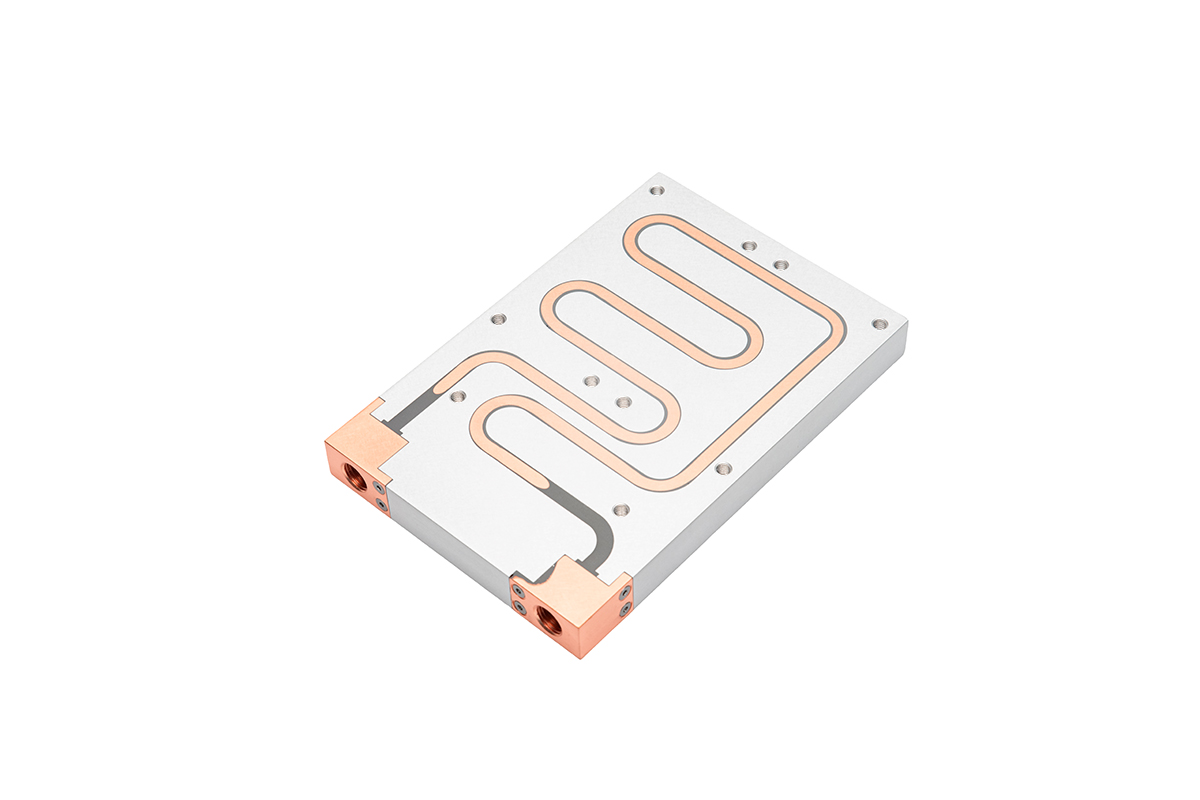

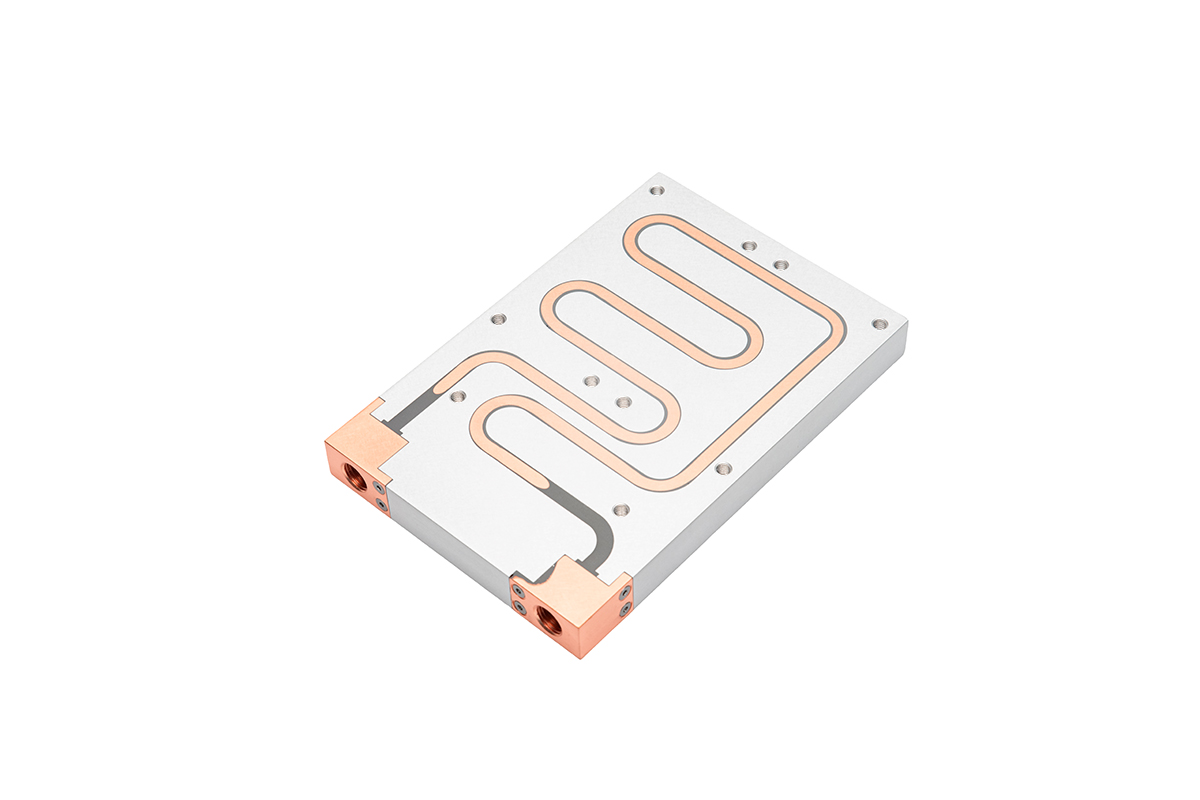

The Aluminum Tubed Liquid Cold Plate with Embedded Copper Tubes (also referred to as Tubed Cold Plate, Liquid Cooled Tubed Cold Plate, Cold Plate with Copper Tubes, Embedded Copper Tube Cold Plate, or Embedded Tube Cold Plate) is a high-performance thermal management solution designed for demanding applications. By combining 6061/6063-T6 aluminum plates with high-purity copper tubes and thermally conductive epoxy or silicone adhesives, this cold plate ensures efficient heat dissipation, structural stability, and long-term reliability in electronic, industrial, and automotive systems.

Our Tubed Cold Plate is engineered to provide uniform cooling across surfaces, maintaining components at optimal operating temperatures. With embedded copper tubes, it achieves direct heat transfer, reducing thermal resistance and enabling compact, high-efficiency designs. The integration of aluminum and copper ensures excellent thermal conductivity, while the adhesive-filled design enhances mechanical strength and prevents leakage under long-term use.

Key features:

High thermal efficiency with low contact thermal resistance.

Strong structural integrity due to precise tube embedding.

Compatibility with various liquids including water, glycol, or dielectric coolants.

Customizable flow channel design to meet specific heat load requirements.

Aluminum Plate (6061/6063-T6): Certificates verified (AMS/ASTM), mechanical tests (tensile strength, yield, hardness), dimensional check (flatness ≤0.1mm, surface finish Ra ≤1.6μm).

Copper Tubes (TP1/C1100): Diameter inspection (φ6mm, φ8mm, custom), roundness ≤0.02mm, straightness ≤0.1 mm/m, RoHS/REACH compliance.

Adhesives: Two-component thermally conductive epoxy or silicone; pre-inspected for sedimentation or crystallization; mixed precisely (±0.1g).

CAD & Simulation: Import customer 3D model → thermal-fluid coupling analysis (CFD+FEA) → optimize tube layout.

Groove Design:

Depth: 42–48% of copper tube OD (φ6mm → 2.5–2.9mm, φ8mm → 3.4–3.8mm).

Protrusion: 0.1–0.3mm for metal-to-metal contact.

Width: Tube OD + 0.1–0.2mm.

Depth tolerance: ±0.05mm.

DFM Review: Aluminum machinability, copper tube tolerance, adhesive flow simulation, thermal stress prediction.

Copper Tube Bending: Minimum bending radius R ≥ 2.5D–3D, wrinkle prevention, programmed on 3D CNC bending machine.

Fixture Design: Positioning, injection, curing, and inspection fixtures.

Aluminum Plate: Cutting (waterjet/laser) → CNC rough & precision machining → groove & tube hole machining → second-side machining (back sealing, threaded ports, installation holes) → deburring, cleaning, drying.

Copper Tubes: Straightening → cutting → end forming → CNC bending → ovality ≤8%, angle & position verified → surface cleaning.

Alkali degreasing 50–60°C → hot water rinse → acid activation (5% HNO₃).

Optional: sandblasting 60–80 mesh, chemical etching, polishing.

Adhesion-promoting coating if required → drying.

Adhesive: Pre-condition to 23±2°C, degassing, precise mixing, bubble-free.

Assembly: Aluminum plate fixed in fixture → copper tubes inserted → low-pressure adhesive injection (overfill 5%) → mild vibration (60Hz, 30s) → surface cleanup → curing.

Room temperature 23±2°C, humidity 50±10%, duration 4–8h, monitored to avoid flow or thickening.

Dimensional: CMM inspection, critical dimensions ±0.05mm, flatness ≤0.1mm, parallelism ≤0.08mm.

Leak Testing: Pressure decay 1.5×working pressure, ≤0.5% drop; optional helium mass spectrometry ≤1×10^-6 mbar·L/s.

Performance: Flow rate 0.5–5 L/min; thermal resistance Rth = ΔT/Q, ±15%; heat load 200–2000W.

Reliability: Salt spray 5% NaCl, 35°C, 48h; check corrosion, delamination, leakage.

Cleaning & drying, protective port plugs, laser marking, shock-resistant foam, moisture-proof & ESD packaging, documentation (material certificates, inspection reports, process records).

| Parameter | Value / Range |

|---|---|

| Aluminum Plate | 6061/6063-T6 |

| Copper Tube | TP1/C1100, OD 6–8mm |

| Tube Wall Thickness | 0.5–1mm |

| Groove Depth | 42–48% of tube OD |

| Tube Protrusion | 0.1–0.3mm |

| Flatness | ≤0.1mm |

| Parallelism | ≤0.08mm |

| Max Pressure | ≤5 bar |

| Flow Rate | 0.5–5 L/min |

| Thermal Resistance | 0.05–0.15 K/W |

| Heat Load | 200–2000W |

| Surface Treatment | Degrease + acid + optional sandblasting |

| Leak Rate | ≤1×10^-6 mbar·L/s (optional) |

High Thermal Efficiency: Embedded copper tubes reduce thermal resistance.

Reliable Sealing: Adhesive-filled design ensures long-term leak-free operation.

Precision Engineering: Groove and tube tolerances ensure uniform assembly.

Customizable Flow Paths: Optimized layout for varying heat loads and fluid types.

Robust Structure: Aluminum-copper integration with mechanical stability.

Wide Compatibility: Works with water, glycol solutions, or dielectric coolants.

Data Centers: Server cooling and high-density computing systems.

Electronics: Power modules, semiconductor devices, LED cooling.

Automotive & EV: Battery and inverter thermal management.

Industrial Equipment: Laser systems, power electronics, machining tools.

Aerospace & Defense: Compact, high-reliability thermal solutions.

Q1: What is the difference between a Tubed Cold Plate and a traditional cold plate?

A1: A Tubed Cold Plate integrates embedded copper tubes for direct liquid cooling, providing higher thermal efficiency and lower thermal resistance compared to plain channels.

Q2: Can the cold plate handle different coolant types?

A2: Yes, it is compatible with water, glycol solutions, or dielectric fluids depending on design and material compatibility.

Q3: What flow rates are supported?

A3: Typical 0.5–5 L/min, adjustable based on design.

Q4: How precise is the copper tube embedding?

A4: Groove depth tolerance ±0.05 mm, tube protrusion 0.1–0.3 mm for optimal metal-to-metal contact, ensuring uniform heat transfer.

Q5: What is the maximum heat load?

A5: Up to 2000 W per unit, depending on cold plate size and design.

Q6: Are customized sizes available?

A6: Yes, Aluminum Tubed Liquid Cold Plates with Embedded Copper Tubes can be custom-designed according to customer heat load, flow path, and dimensional requirements.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018