Hot Stamping Automotive Parts refer to vehicle components manufactured using advanced hot Stamping technology, a state-of-the-art forming method developed for ultra-high strength steel (UHSS). This technique plays a critical role in the production of structural automotive components that meet the industry's growing demands for safety, weight reduction, and performance.

Hot Stamping is a thermo-mechanical process where boron steel blanks are heated above the austenitization temperature (~900°C), fully austenitized, and then rapidly transferred to a cooled die for forming and quenching in a single operation. This results in martensitic transformation, giving parts strength up to 1500 MPa or more, while achieving high dimensional accuracy.

Hot stamped parts can reach tensile strengths of 1500 MPa or higher, significantly enhancing crash performance. At the same time, optimized part design and material usage reduce weight, supporting better fuel efficiency and emissions compliance.

Forming at elevated temperatures allows for complex shapes and deep drawn parts with minimal springback. The result is tight tolerance components that require little to no post-processing.

Using aluminized boron steel or applying zinc coatings, hot stamped components offer high resistance to oxidation, chemicals, and harsh environments—ideal for both internal and external automotive parts.

Hot stamping lines are optimized for high-volume production, enabling automotive manufacturers to produce large batches of safety-critical parts with consistent quality.

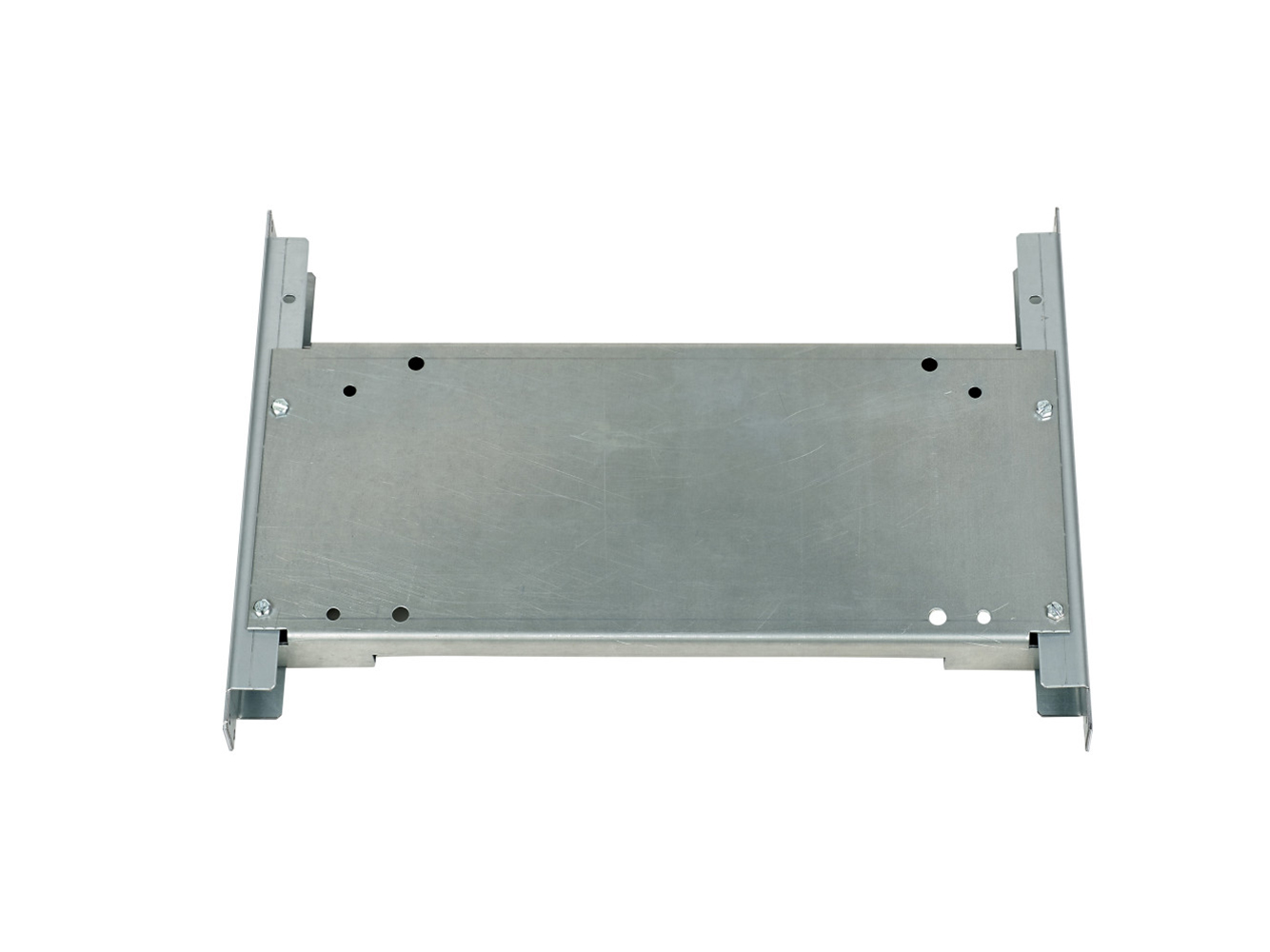

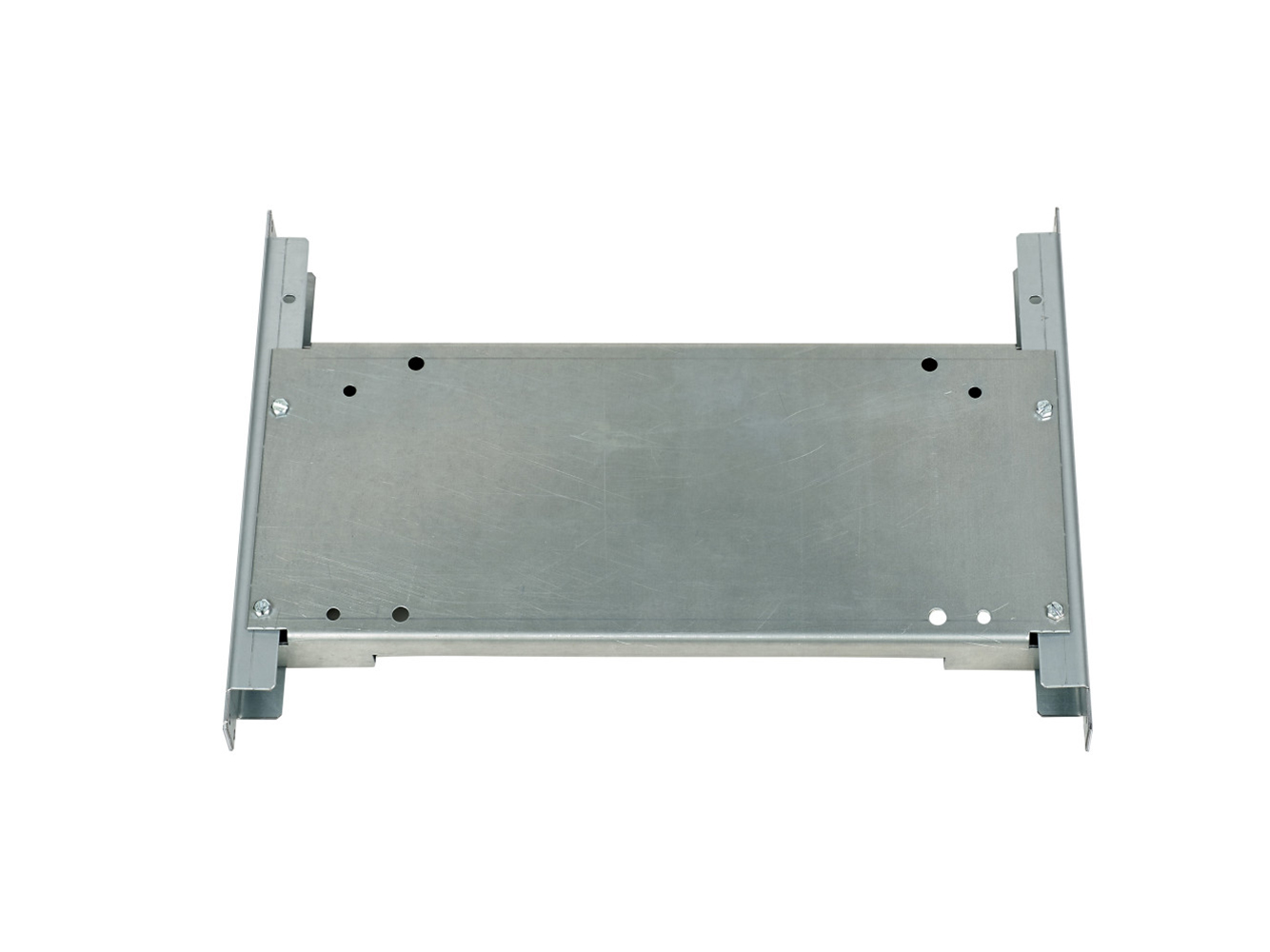

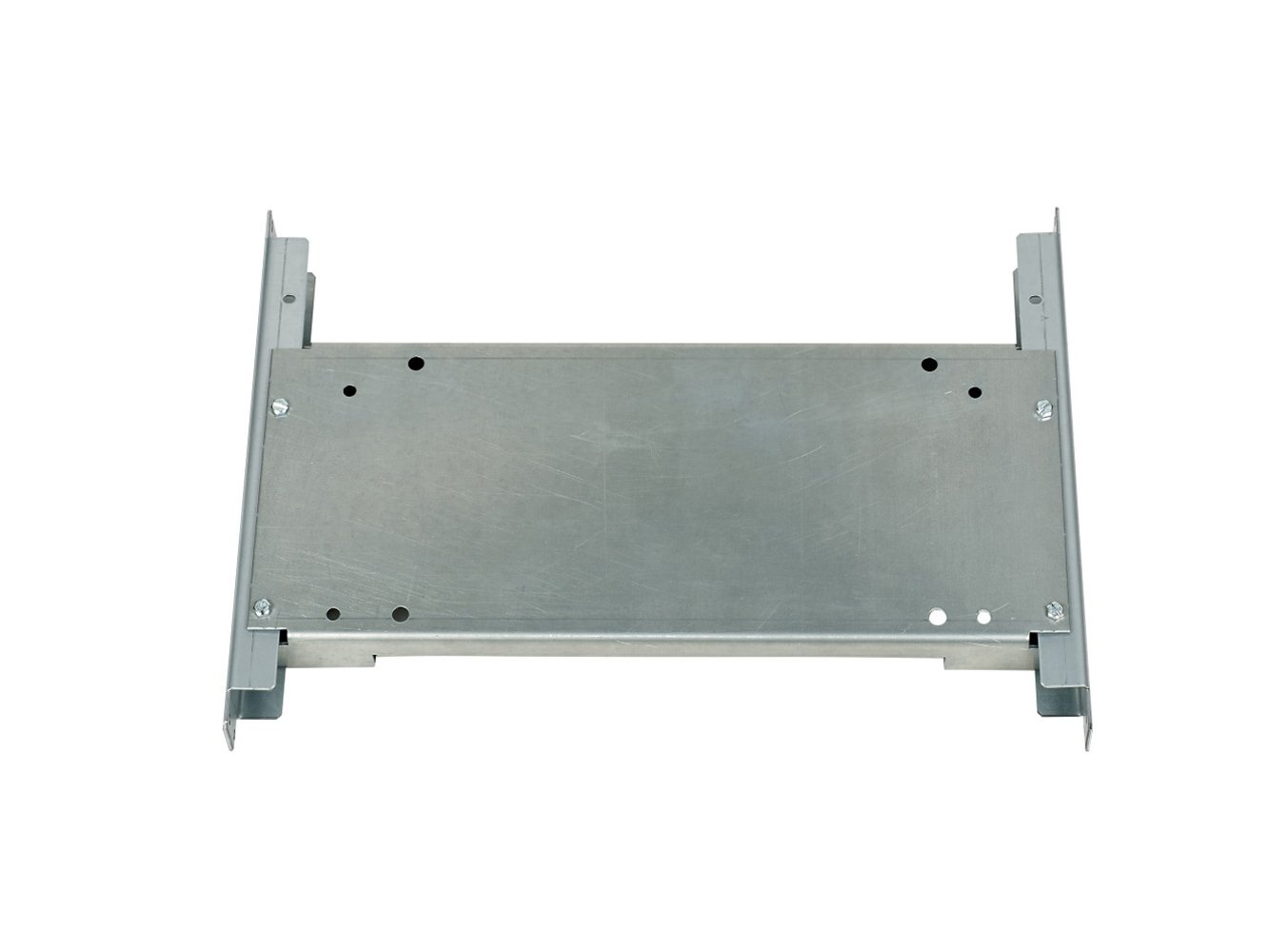

Hot stamping parts are widely used in the body-in-white (BIW) and chassis systems of modern vehicles, including:

Body Structure: A-pillars, B-pillars, roof rails, side sills, floor tunnels

Crash Safety Components: Door intrusion beams, bumper reinforcements, crash boxes

Chassis Components: Suspension brackets, subframes, seat frames

Interior & Underbody Parts: Cross members, battery housings (for EVs), reinforcements

These components play vital roles in crash energy absorption, body stiffness, passenger protection, and overall vehicle integrity.

| Function | Description |

|---|---|

| Structural Support | Reinforces vehicle frame and absorbs road or collision loads |

| Safety Protection | Enhances crash performance by maintaining cabin integrity during impact |

| Component Integration | Facilitates welding, bolting, and modular integration in vehicle assembly |

| Vehicle Performance | Supports better driving dynamics through lighter weight and stronger parts |

Maintenance & Upkeep Tips

To ensure long-term reliability of hot stamping automotive parts:

Regular Inspection: Check for cracks, deformation, or corrosion in structural and safety-critical areas.

Surface Cleaning: Use soft cloths and neutral cleaners to avoid damaging protective coatings.

Lubrication (if applicable): Keep moving hot-stamped components properly lubricated to reduce wear.

Avoid Mechanical Impact: Protect components from collision during service, transport, or parking.

Professional Replacement: Severely worn or damaged parts should be repaired or replaced by qualified technicians.

Use Correct Tools for Disassembly: Prevent deformation during repair.

Follow Manufacturer’s Guidelines: Each OEM part may have different maintenance procedures.

Rust Prevention: In highly corrosive environments, apply protective coatings or oils as needed.

Inspect Connection Points: Regularly check welds and bolts to prevent failure at joints.

ISO/TS 16949-Certified Manufacturing

Custom Part Design & Tooling

OEM & Tier 1 Automotive Supplier Experience

Full Traceability & Material Certifications

Support for Prototypes & Mass Production

Advanced Simulation & CAE Forming Analysis

Packaging: Anti-corrosion wrap + foam protection + wooden crate (optional for export)

Delivery: Global shipping by air, sea, or courier; support for JIT/automotive line delivery

MOQ: Flexible – from samples to large-scale production

A: Hot stamping automotive parts are vehicle components made from ultra-high strength steel that is heated and formed at high temperatures, then rapidly cooled in a mold. This process increases strength, precision, and safety performance.

A: The primary material is boron steel (such as 22MnB5), often aluminized or zinc-coated for corrosion resistance. It is specially designed for high-strength applications in automotive structures.

A: Key advantages include high strength (up to 1500 MPa), lightweight design, excellent crash resistance, minimal springback, and high dimensional precision.

A: They are commonly used in body-in-white structures like A-pillars, B-pillars, door reinforcements, bumper beams, roof rails, and crash beams.

A: Yes, we offer OEM/ODM customization services, including part design, tool development, and simulation to meet your specific automotive application needs.

A: Regular inspections, surface cleaning, corrosion protection in harsh environments, and careful handling are key to maintaining performance and longevity.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018