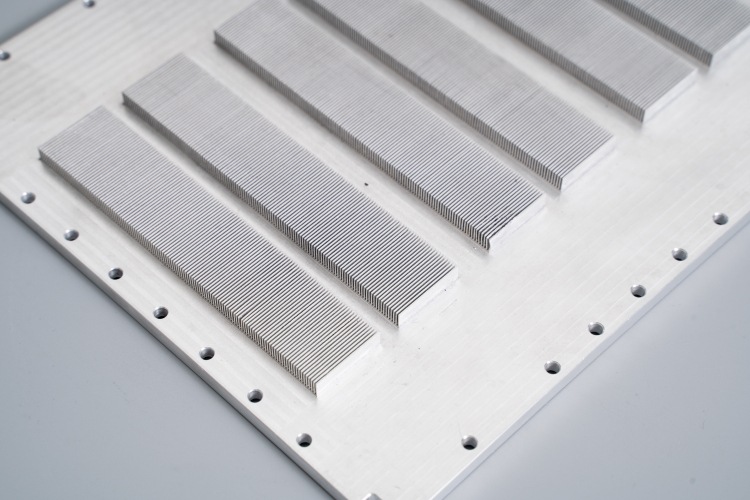

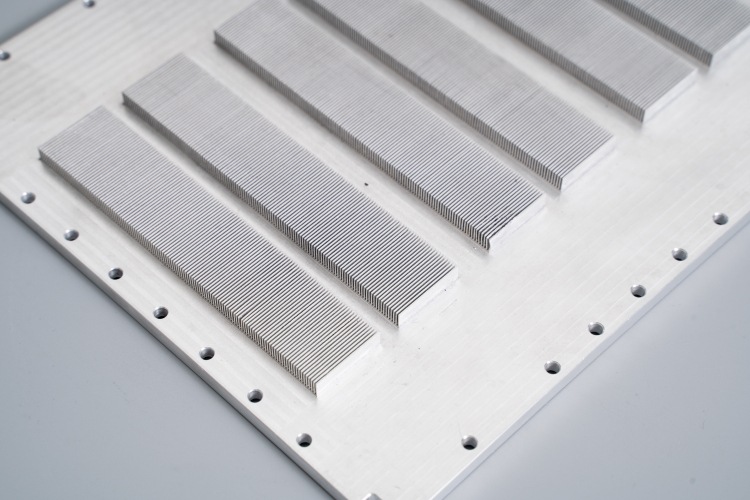

The main material used for Aluminum Skived Fin Heat Sink Parts is aluminum alloy, especially 1060 aluminum alloy. 1060 aluminum alloy is a high-quality heat dissipation material with lightweight, efficient heat dissipation and corrosion resistance. It can effectively transfer heat from the heat source to the surface of the heat sink, and dissipate heat to the surrounding environment through air convection or fan forced convection.

Thickness

The thickness of the Heat Sink is one of the important factors affecting its heat dissipation performance. Generally speaking, the thinner the thickness of the heat sink, the larger its heat dissipation area and the better the heat dissipation effect. However, a heat sink that is too thin may reduce its structural strength and durability. Therefore, when designing and manufacturing heat sinks, factors such as heat dissipation performance, structural strength and durability need to be comprehensively considered to determine the appropriate thickness.

Specific to aluminum chipped heat sinks, the thickness can be determined according to customer needs and heat dissipation requirements. In high-performance electronic devices, the thickness of the heat sink may be only a few millimeters, while in some large industrial equipment, the thickness of the heat sink may be thicker.

KingKa's inspection of aluminum chipped heat sinks mainly includes the following aspects:

Appearance inspection: Observe the surface quality of the heat sink visually or under a microscope, including whether there are defects such as cracks, scratches, oxidation, etc.

Dimension inspection: Use measuring tools (such as vernier calipers, micrometers, etc.) to detect whether the size of the heat sink meets the design requirements, including thickness, length, width, etc.

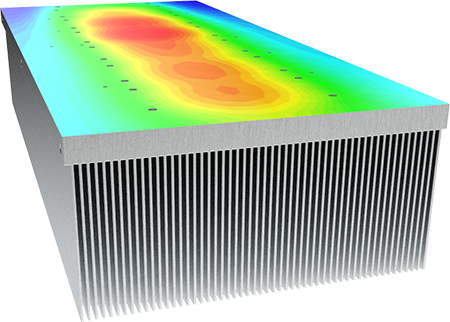

Performance test: Use thermal testing equipment to detect the heat dissipation performance of the heat sink, including parameters such as heat dissipation efficiency and thermal resistance. This usually needs to be done under specific test conditions, such as constant heat source temperature, wind speed, etc.

Material testing: Use chemical analysis methods (such as spectral analysis, energy spectrum analysis, etc.) to detect whether the material composition of the heat sink meets the requirements. This helps to ensure that the heat sink uses high-quality aluminum alloy materials.

Aluminum chipped heat sinks have the following significant advantages:

Efficient heat dissipation: Because the heat sink is manufactured using the chipping process, it has a large heat dissipation area and high heat dissipation efficiency. This helps to quickly transfer heat to the surrounding environment and reduce the temperature of the equipment.

Lightweight and durable: Aluminum alloy materials are lightweight and high-strength, so that the heat sink has good durability and corrosion resistance while ensuring heat dissipation performance.

Easy to process: Aluminum alloy materials are easy to process and form, and heat sinks of various shapes and sizes can be manufactured to meet the needs of different equipment.

Cost-effectiveness: Compared with other heat dissipation materials, the price of aluminum alloy materials is relatively low, making aluminum chipped heat sinks highly cost-effective.

Aluminum chip heat sinks are widely used in various electronic devices that require heat dissipation, including but not limited to the following aspects:

Computers and servers: In computers and servers, high-performance processors such as CPUs and GPUs require efficient heat dissipation solutions to maintain their stable operation. Aluminum chip heat sinks have become a commonly used heat dissipation component in these devices due to their efficient heat dissipation and lightweight and durable characteristics.

Communication equipment: In communication equipment, such as base stations, routers, etc., efficient heat dissipation solutions are also required due to the need to run for a long time and process a large amount of data. Aluminum chip heat sinks can provide stable heat dissipation performance to ensure the normal operation of communication equipment.

Industrial equipment: In some large industrial equipment, such as inverters, power supplies, etc., heat sinks are also needed to reduce the temperature of the equipment. Aluminum chip heat sinks are also widely used in these devices due to their efficient heat dissipation and easy processing.

Automotive electronics: In the field of automotive electronics, such as car chargers, car entertainment systems, etc., heat sinks are also needed to ensure the stable operation of the equipment. Aluminum chip heat sinks have become a commonly used heat dissipation component in these devices due to their lightweight, durable and cost-effective characteristics.

LED lighting: In the field of LED lighting, since LED lamps generate a lot of heat when working, heat sinks are needed to reduce the temperature of the lamps. Aluminum skived fin heat sinks are also widely used in the field of LED lighting due to their high efficiency in heat dissipation and easy processing.

Aluminum skived fin heat sink parts have broad application prospects in the field of electronic equipment heat dissipation due to their advantages of high efficiency in heat dissipation, light weight and durability, easy processing and cost-effectiveness. With the continuous development of science and technology, aluminum skived fin heat sinks will continue to play an important role in the future and provide strong guarantee for the stable operation of various electronic equipment. Welcome to contact KingKa to customize the Aluminum Skived Fin Heat Sink Parts you need.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018