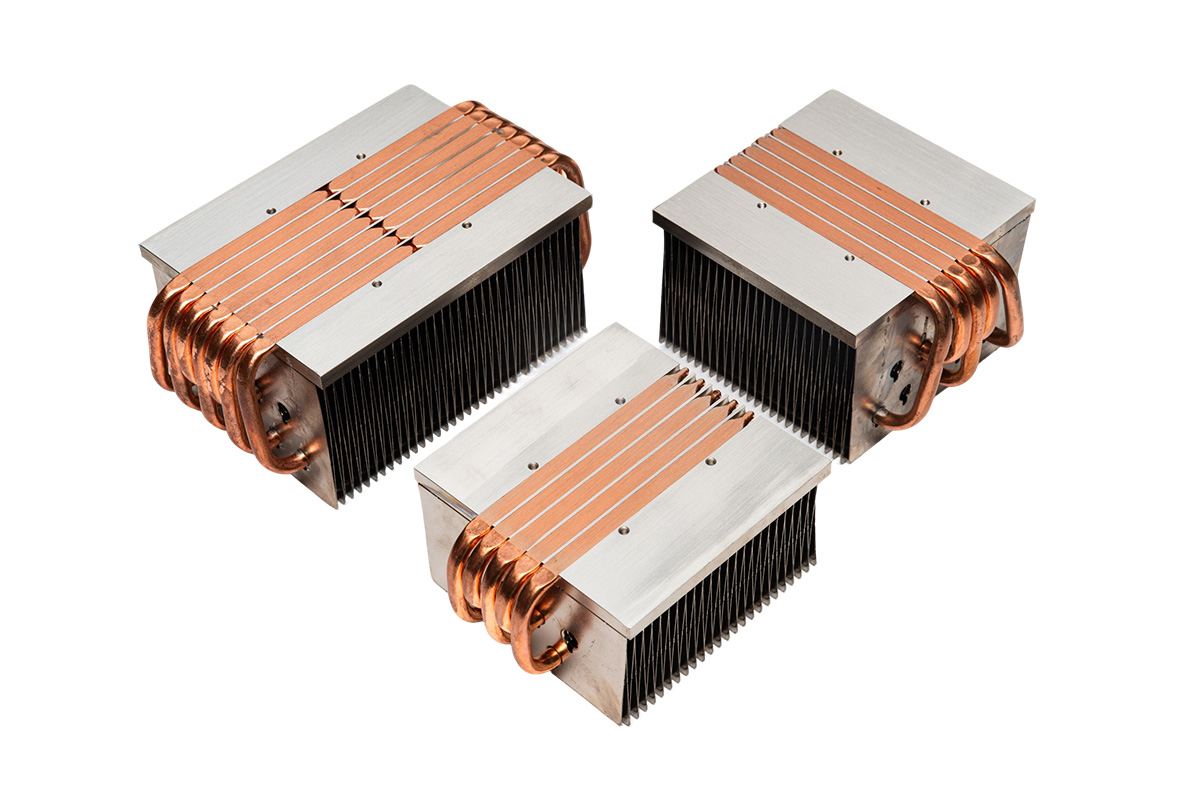

The Zipper Fin Heat Sink is a cutting-edge thermal management solution designed for high-performance electronic devices. It is engineered to efficiently dissipate heat, ensuring stable operation and extended lifespan for sensitive components. Also known as a zipper fin heatsink, this innovative design combines advanced manufacturing techniques with superior materials to provide unmatched cooling performance.

A high-performance zipper fin heat sink is built to maximize heat transfer efficiency by increasing the surface area exposed to air or liquid cooling. Unlike traditional heat sinks, the zipper fin design features interlocking fins resembling a zipper, which enhances airflow and reduces thermal resistance. This makes the zipper fin cooler ideal for applications requiring high thermal conductivity and reliable cooling under heavy loads.

These heat sinks are often paired with custom heatsink solutions to fit specific electronic layouts, allowing designers to optimize cooling in compact or complex environments.

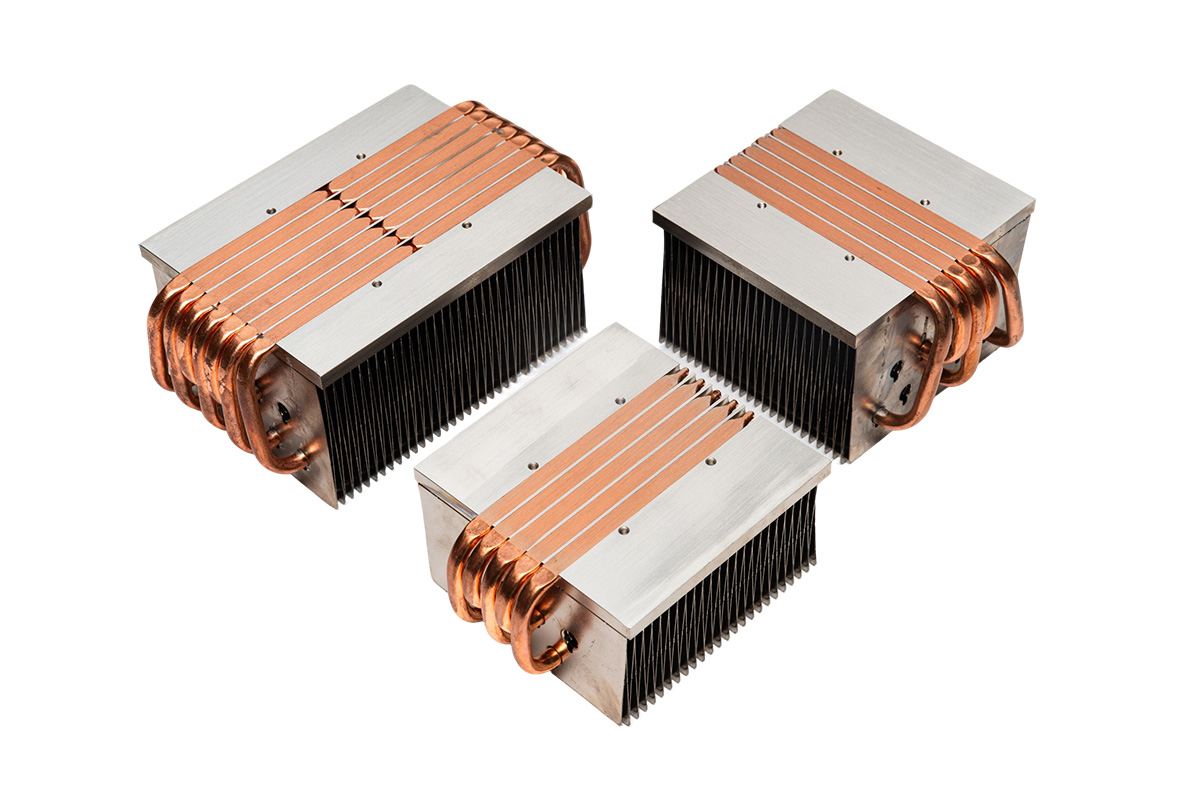

The Zipper Fin Heat Sink is commonly fabricated from high-quality copper or aluminum, depending on the thermal requirements:

skived copper heatsink: Copper is known for its excellent thermal conductivity, making copper skiving an ideal method for creating thin, high-density fins.

Aluminum option: Lightweight and cost-effective, suitable for applications where weight is a concern.

The manufacturing process often involves skiving heat sink techniques, also called heat sink skiving. In skiving, a block of metal is precisely sliced to form thin fins while maintaining a solid base for thermal conduction. This results in a skived fin heat sink or skived heatsink, where fins are closely spaced for superior airflow and enhanced heat dissipation.

Key advantages of skived fin designs include:

High thermal performance due to increased surface area

Precise fin thickness and spacing

Excellent mechanical strength for durable applications

The Zipper Fin Heat Sink leverages the principles of skiving heat sink technology to provide maximum cooling efficiency. Key design features include:

Interlocking Fins: The zipper-style fins create turbulence in the airflow, improving heat transfer through convection.

High-Density Fins: Skiving allows for thinner and denser fins compared to extrusion methods, increasing the surface area without adding bulk.

Direct Thermal Path: A solid base connects directly to the heat source, ensuring minimal thermal resistance.

Customizability: Custom heatsink designs can adjust fin length, spacing, and material to meet specific power dissipation requirements.

The combination of skived fin technology and zipper-style layout ensures that these heat sinks maintain optimal performance even under high-power operation.

Typical specifications for a Zipper Fin Heat Sink include:

Material: Copper (skived) or aluminum

Fin Height: 10–50 mm (depending on application)

Fin Thickness: 0.1–0.5 mm for skived copper

Base Thickness: 3–10 mm

Thermal Conductivity: Up to 400 W/m·K for copper skived heatsinks

Dimensions: Customizable according to device layout

Surface Treatment: Nickel plating or anodizing for corrosion resistance

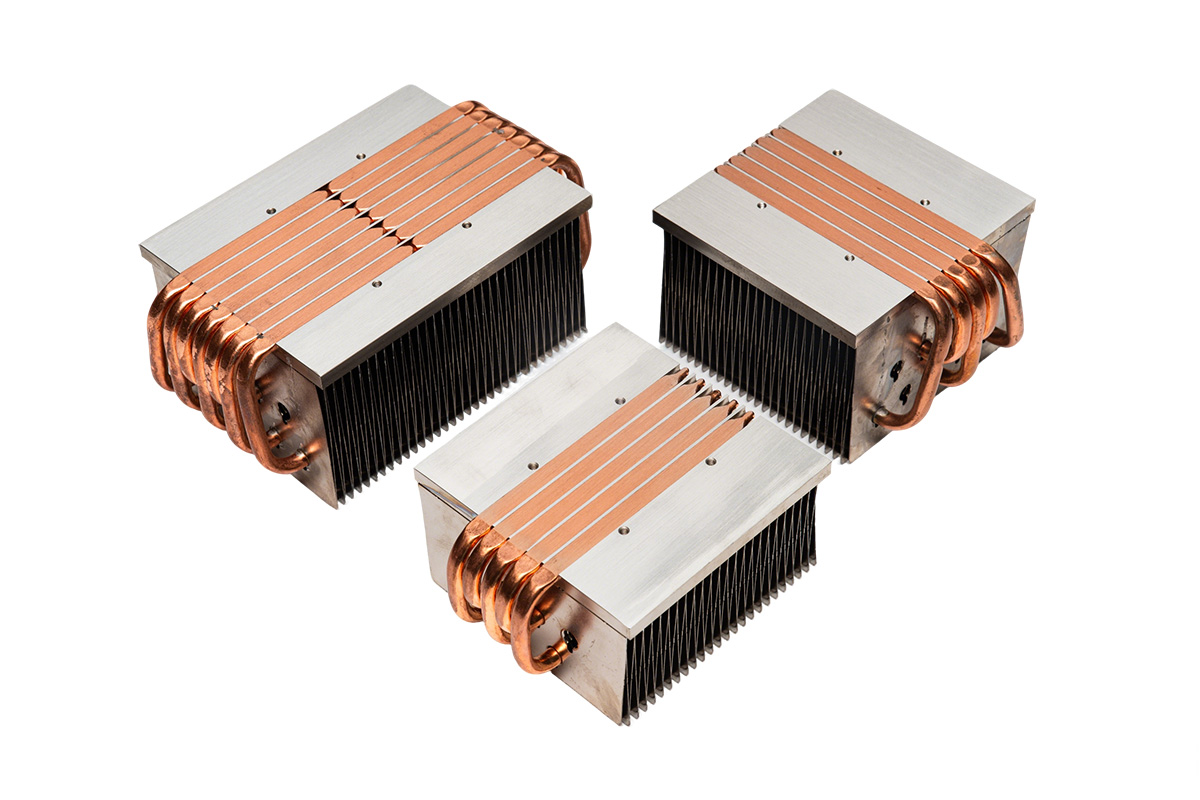

The zipper fin heatsink is suitable for a wide range of high-performance electronic applications, including:

Power electronics: Voltage regulators, inverters, and power modules

Computing devices: CPU and GPU cooling for high-performance computing

LED lighting: High-power LED modules that generate significant heat

Telecommunication equipment: Routers, servers, and base stations

Industrial electronics: Motor drivers, amplifiers, and other heavy-duty electronics

Thanks to its superior thermal management, the high-performance zipper fin heat sink ensures stable operation, increased reliability, and longer component life.

Choosing a zipper fin cooler provides several advantages over traditional heat sinks:

Enhanced heat dissipation through skived fin technology

Increased airflow due to interlocking fin design

Ability to create custom heatsink solutions for unique applications

High durability and corrosion resistance

Compatible with both copper skiving and aluminum manufacturing

Whether you need a skived heatsink for a high-power CPU or a zipper fin heatsink for industrial power electronics, this design ensures optimal thermal performance in compact and high-density layouts.

A Zipper Fin Heat Sink is a high-performance cooling solution designed to dissipate heat from electronic components. It features interlocking “zipper-style” fins that increase airflow and improve thermal efficiency. These heat sinks are often used in high-power devices and can be customized as a custom heatsink.

The zipper fin heatsink works by conducting heat from the electronic component into its base and transferring it to the fins. The interlocking fins create turbulence in the airflow, improving convection cooling. When combined with skived fin heat sink technology, the thin, closely spaced fins maximize surface area, allowing more heat to be dissipated quickly.

Zipper Fin Heat Sinks are typically made from:

Copper: High thermal conductivity; often produced as a skived copper heatsink using copper skiving technology.

Aluminum: Lightweight and cost-effective, commonly used in skived heatsink designs or extrusion-based models (heat sink extrusion).

Both materials allow for high-performance zipper fin heat sink solutions suitable for CPUs, LED modules, power electronics, and other high-power devices.

A standard heat sink may use simple straight fins, while a zipper fin cooler features interlocking fins that enhance airflow and improve heat dissipation. Combined with skived fin or skiving heat sink techniques, zipper fin designs provide higher thermal efficiency in a compact size, making them ideal for demanding electronic applications.

Yes, custom heatsink solutions are widely available. Manufacturers can adjust fin height, thickness, spacing, base size, and material (copper or aluminum) to meet specific thermal requirements. Zipper fin heatsink customization ensures optimal performance for compact devices or unique layouts.

High-performance zipper fin heat sinks are used in:

CPU and GPU cooling for computers and servers

LED modules and lighting systems

Power electronics, including inverters, voltage regulators, and motor drivers

Industrial electronics like amplifiers and high-power controllers

Telecommunication equipment, such as routers and base stations

Increased thermal efficiency due to skived fin design

Enhanced airflow with interlocking fins (zipper fin cooler)

Supports custom heatsink solutions for specific applications

Can be made from copper or aluminum depending on thermal requirements

Compact and high-performance cooling for dense electronic layouts

Skived fin heat sinks (or skived heatsink) are made by slicing thin fins directly from a metal block, providing higher fin density and better surface area compared to traditional heat sink extrusion methods. When combined with zipper fin heatsink design, this allows for superior thermal performance in tight spaces.

Absolutely. The combination of high-performance zipper fin heat sink design and skived copper heatsink technology allows for rapid heat dissipation, making them ideal for high-power CPUs, GPUs, LED modules, and industrial power electronics.

Yes. Zipper fin heatsinks can be paired with fans, heat pipe thermal modules, or liquid cooling solutions to enhance cooling efficiency further. The combination of skived fin design and additional cooling ensures devices maintain optimal operating temperatures even under heavy loads.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018