KINGKA Tech Industrial Limited, founded in 2010, is a professional manufacturer specializing in aluminum alloy thermal solutions. Our main products include high-performance Heat Sinks and Liquid Cold Plates, designed to meet the most demanding thermal management requirements in industries such as telecom, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting, and multimedia/consumer applications.

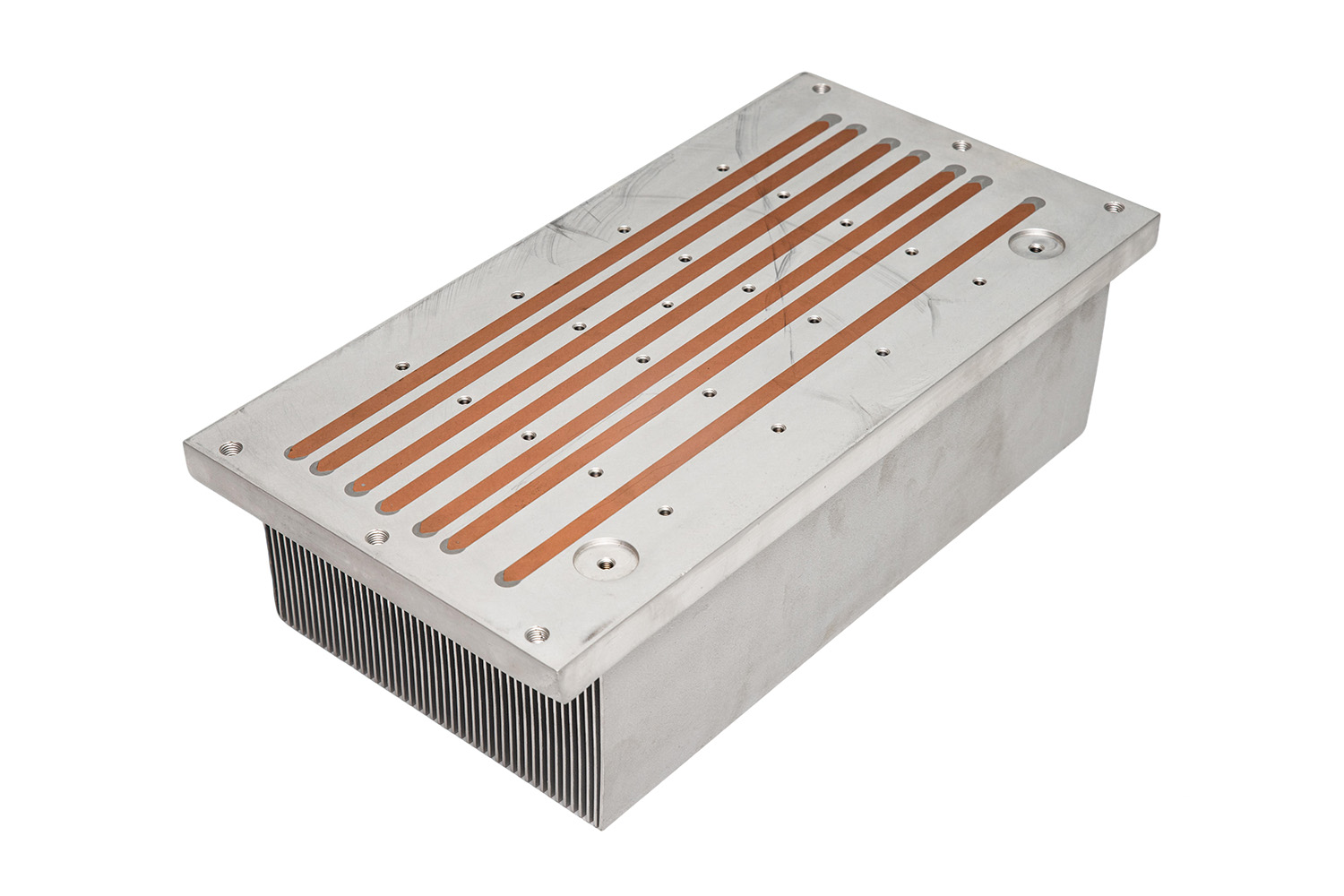

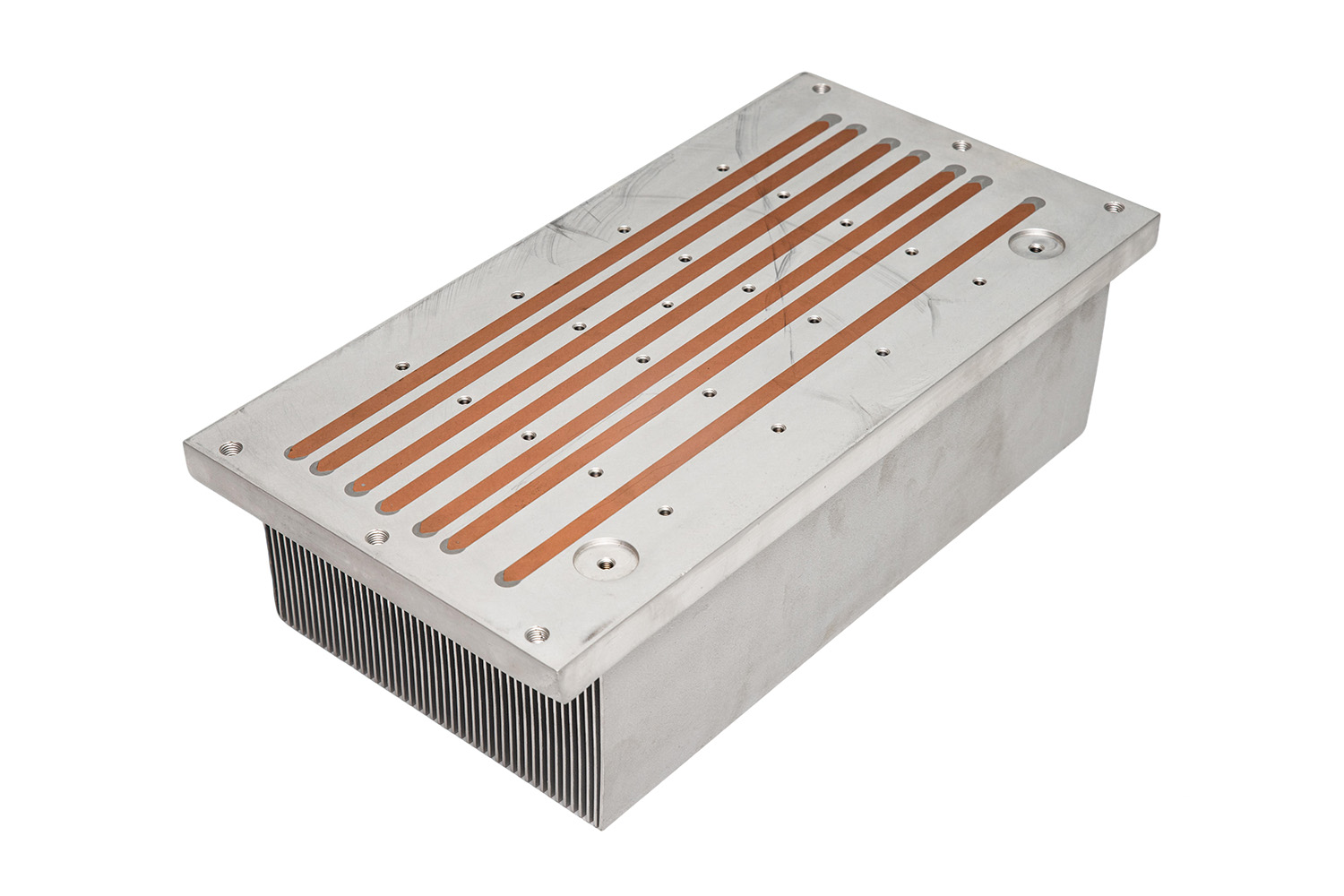

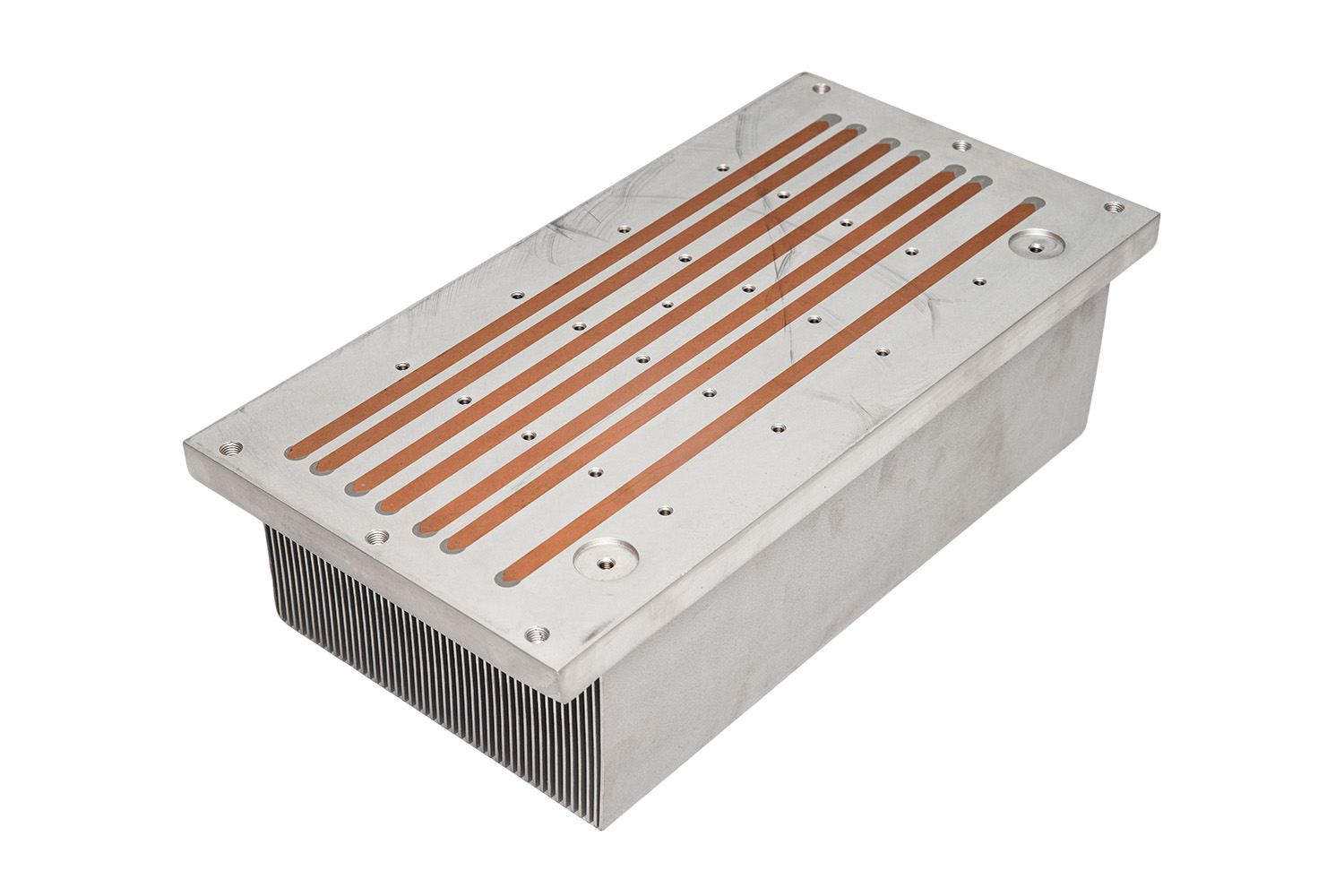

The Aluminum Skiving Fin Heat Sink is an advanced cooling component produced by a high-precision skiving process, which slices ultra-thin fins directly from a solid aluminum or copper block. This technique ensures excellent thermal conductivity, high fin density, and superior heat dissipation performance compared with traditional heat sink extrusion or die-cast methods. It is widely used where compact size, high efficiency, and lightweight design are essential.

High-Efficiency Thermal Performance:

The Skived Fin Heat Sink provides a large surface area and minimal thermal resistance, allowing rapid heat transfer from electronic components to the surrounding air.

Premium Aluminum Material:

Made from aluminum heat sink material such as AL1050, AL6061, or AL6063, ensuring excellent heat conduction and lightweight structure.

Compact and Flexible Design:

Customizable heat sink design to fit space-limited enclosures and high-power density devices. Fins can reach as thin as 0.2 mm, maximizing airflow efficiency.

Custom Manufacturing:

As a custom heatsink manufacturer, KINGKA provides design optimization, thermal simulation, and OEM/ODM production services for different applications.

Strong Mechanical Integrity:

The continuous base-to-fin structure ensures superior durability and reduces the risk of fin detachment compared to bonded or soldered types.

Surface Finishing Options:

Includes anodizing, nickel plating, powder coating, and sandblasting for improved corrosion resistance and thermal radiation.

| Specification | Details |

|---|---|

| Product Name | Aluminum Skiving Fin Heat Sink |

| Manufacturer | KINGKA Tech Industrial Limited |

| Material Options | Aluminum (AL1050, AL6061, AL6063), Copper (C1100, C1020) |

| Heat Sink Type | skived fin Heat Sink / Pin Fin Heat Sink / extruded heat sink |

| Process Technology | Skiving Process + CNC Machining + Surface Treatment |

| Thermal Conductivity | Aluminum: 180–220 W/m·K; Copper: 380–400 W/m·K |

| Fin Thickness | 0.2–1.0 mm (customizable) |

| Fin Height | 5–60 mm |

| Fin Pitch | 0.5–3 mm |

| Base Thickness | 2–10 mm (depending on heat load) |

| Dimension Range | Up to 400 mm length (custom sizes available) |

| Surface Treatment | Anodizing (black/silver/natural), Nickel Plating, Powder Coating |

| Operating Temperature | -40°C ~ +150°C |

| Thermal Resistance | ≤0.05°C/W (depends on design and airflow) |

| Mounting Method | Thermal Pads, Screws, Clips, or Adhesive Bonding |

| Application Power Range | 10W–1500W (depending on fin density and airflow) |

| Certifications | ISO9001:2015, CE, RoHS |

| Customization Service | OEM/ODM Design, Rapid Prototyping, Thermal Simulation |

| Lead Time | 15–30 working days |

Superior Thermal Efficiency:

Compared with traditional heat sink extrusion or bonded fin methods, the skived fin heat sink offers better thermal performance due to continuous material structure and thin fin capability.

Lightweight Aluminum Structure:

The aluminum heat sink material provides excellent thermal conductivity with lower weight, ideal for compact and mobile electronic systems.

Customizable Designs:

KINGKA, as a leading custom heatsink manufacturer, supports full customization for heat sink design, size, fin density, and surface finishing.

Cost-Effective and Scalable Production:

The skiving process allows mass production without expensive molds, providing faster lead times and competitive pricing.

Reliable and Durable:

The solid mechanical bonding between the base and fins enhances long-term stability and heat dissipation consistency.

KINGKA’s Aluminum Skiving Fin Heat Sinks are widely applied in:

Telecommunication equipment (base stations, servers, routers)

Automotive electronics (EV controllers, inverters, LED headlights)

Aerospace systems (avionics and onboard power modules)

Industrial control equipment (PLC, variable frequency drives)

Power electronics (IGBT, MOSFET, rectifiers)

LED lighting and displays (high-power LED modules)

Medical devices (diagnostic and imaging equipment)

Consumer and multimedia electronics (gaming consoles, projectors, amplifiers)

Material Selection:

Choose high-purity aluminum heat sink material or copper blocks based on required thermal performance.

Skiving Process:

Precision blades slice ultra-thin fins from a solid block, maintaining perfect base-to-fin continuity for optimal heat flow.

CNC Machining:

Machined surfaces ensure dimensional accuracy and easy mounting with power devices.

Surface Treatment:

Anodizing or nickel plating enhances corrosion resistance and improves heat radiation.

Inspection & Testing:

Every heat sink undergoes strict thermal resistance and mechanical stability tests to ensure reliability.

Q1: What is a Heat Sink?

A heat sink is a passive cooling device that dissipates heat from electronic components into the surrounding air or liquid through conduction and convection.

Q2: What makes a Skived Fin Heat Sink different from an Extruded Heat Sink?

The skived fin heat sink is manufactured by slicing fins directly from a solid block, resulting in thinner fins and better thermal performance than an extruded heat sink.

Q3: Why use Aluminum for Heat Sinks?

Aluminum heat sink material combines excellent thermal conductivity, lightweight structure, and corrosion resistance, making it ideal for most thermal applications.

Q4: Can KINGKA provide custom heat sink designs?

Yes. As a custom heatsink manufacturer, KINGKA offers complete heat sink design, simulation, and prototyping services tailored to your project requirements.

Q5: What industries use Skived Fin Heat Sinks?

They are used in telecom, automotive, aerospace, power electronics, industrial control, and LED lighting applications requiring efficient thermal management.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018