With the rapid growth of data centers, AI computing, and high-performance electronic systems, heat flux density continues to increase while available installation space becomes more limited. Conventional extruded or bonded heat sinks often struggle to meet these thermal challenges.

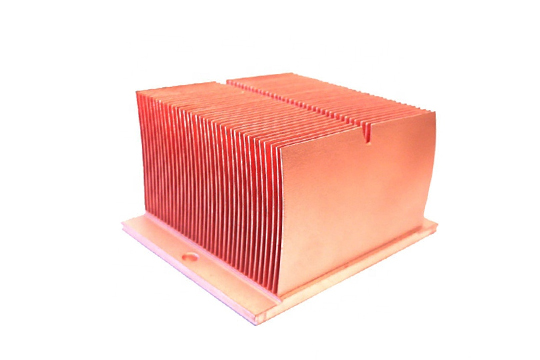

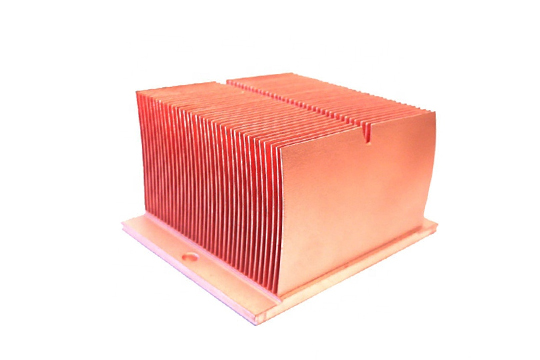

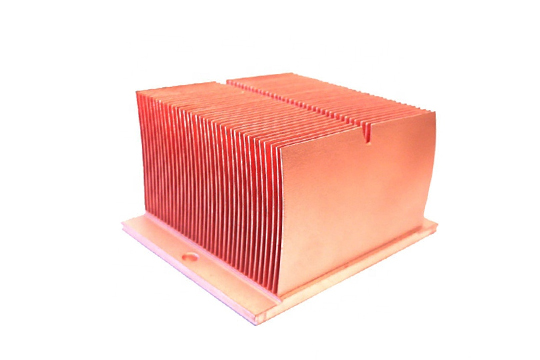

Skived Fin Heat Sinks provide a highly efficient and reliable air-cooling solution by enabling ultra-dense fin structures formed directly from a solid metal base. Through advanced heat sink skiving technology, thermal resistance is minimized, making skived fin heat sinks ideal for high-power and high-reliability applications.

A skived fin heat sink—also referred to as a skived heatsink or skiving heat sink—is manufactured using a precision skiving process. During this process, a specialized cutting tool gradually slices thin layers of metal from a solid aluminum or copper block and lifts them into vertical fins.

Unlike extrusion, brazing, or bonded-fin processes, skived fin structures remain fully integrated with the base material, creating a monolithic heat sink with no thermal interface between fins and base.

This structure significantly improves heat conduction efficiency and mechanical strength.

Because the fins and base are formed from the same piece of material, there is no solder layer, adhesive, or brazing interface. This eliminates interface thermal resistance and ensures direct heat flow from the heat source to the fins.

The skiving process allows:

Thinner fin thickness

Smaller fin pitch

Higher fin aspect ratio

This results in a much larger heat dissipation surface area compared to traditional extruded heat sinks.

High-density skived fins increase turbulence in forced-air environments, improving convective heat transfer when paired with fans or ducted airflow.

Common alloys: Aluminum 6061 / 6063

Lightweight and cost-effective

Suitable for most server, telecom, and industrial air-cooling applications

Manufactured through copper skiving

Extremely high thermal conductivity

Ideal for high heat flux applications where rapid heat spreading is critical

Commonly used in AI accelerators, GPUs, and power modules

Skived copper heatsinks are often selected when performance is prioritized over weight and material cost.

Our skiving heat sink production follows a tightly controlled, step-by-step process to ensure consistency, precision, and traceability.

Aluminum or copper coil material incoming inspection

RoHS / REACH compliance testing

Material certificate verification

Batch traceability and controlled warehouse storage

Review of customer drawings and 3D models

Skived fin feasibility analysis

DFM (Design for Manufacturability) report

Process route confirmation with customer

CAM programming for skiving and CNC operations

Custom fixture design

First article inspection plan preparation

Base Preparation

Coil material feeding and blank cutting

CNC rough machining and reference surface creation

Fin Skiving

Dedicated skiving machine setup

Tool installation and calibration

First article skived fin inspection

Adjustment of fin height, pitch, and geometry

Mass production skiving with real-time monitoring of:

Tool wear

Fin consistency

Surface finish

Precision Machining

CNC finishing of mounting holes, threads, and locating features

Chamfering and deburring

Ultrasonic cleaning to remove oil and debris

Drying process

Optional surface treatments:

Anodizing (natural, black, custom colors)

Electroless nickel plating

Sandblasting

Polishing (mirror or brushed finish)

Secondary cleaning and drying

CMM inspection: fin height, fin pitch, flatness, parallelism

Optical inspection of fin profile and angles

Visual inspection for scratches, dents, or coating defects

Optional salt spray testing

Coating adhesion testing (when applicable)

Anti-static and anti-scratch packaging

Desiccant placement

Optional vacuum packaging

Labeling with part number, batch number, and inspection status

Complete documentation delivery:

Dimensional inspection reports

Material certificates

Quality inspection records

| Process | Control Parameter | Inspection Method | Standard |

|---|---|---|---|

| Skived Fin | Fin height tolerance | Optical projector / CMM | ±0.05 mm |

| Skived Fin | Fin pitch consistency | Optical comparator | ±0.02 mm |

| Surface Treatment | Coating thickness | Thickness gauge | Customer spec ±10% |

| Appearance | Surface defects | Visual / AOI | No visible defects |

Data center servers

AI computing and GPU modules

Telecom and 5G equipment

Power electronics and inverters

Industrial automation systems

High-reliability embedded systems

Higher fin density than extruded heat sinks

Lower thermal resistance than bonded or brazed designs

Strong mechanical integrity and long service life

Excellent performance under forced-air cooling

Highly customizable for complex thermal requirements

Q1: What makes skived fin heat sinks better than extruded heat sinks?

Skived fin heat sinks offer higher fin density and lower thermal resistance, making them suitable for higher power densities and compact designs.

Q2: When should I choose a skived copper heatsink?

When heat flux is extremely high or rapid heat spreading is required, skived copper heatsinks provide superior performance.

Q3: Can skived fin heat sinks be customized?

Yes. Fin geometry, base thickness, mounting features, and surface treatments can all be customized.

Q4: What is the typical production lead time?

Standard lead time is 7–15 working days, depending on complexity and quantity.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018