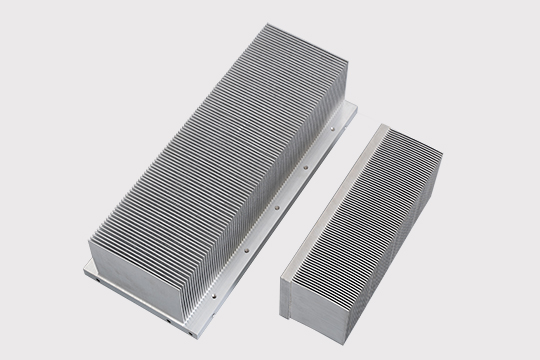

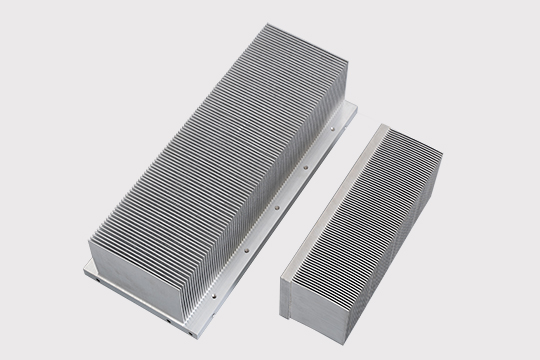

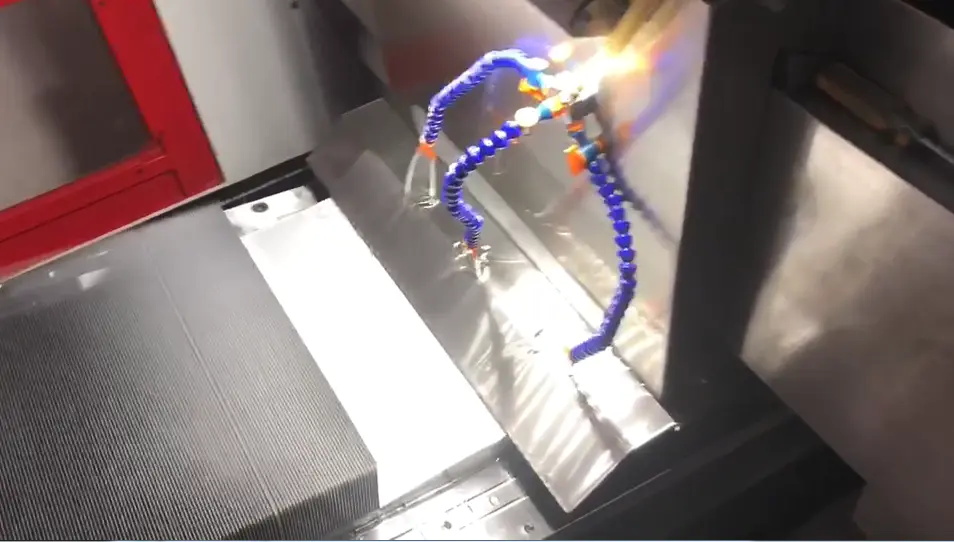

Skived Fin Heat Sink is a heat sink component made by Skived Fin process. This process forms a piece of metal into a Heat Sink with fins, and forms a consistent gap and structure between the fins, thereby enhancing the heat dissipation capacity of the Heat Sink.

Application Material

Skived Fin Heat Sink Parts are mainly used in copper and aluminum. Copper is widely used due to its high thermal conductivity, especially in applications that require high heat dissipation performance. However, copper is relatively expensive and is easily deformed during processing. Aluminum is a lightweight, inexpensive and easy-to-process metal. Although its thermal conductivity is slightly inferior to copper, it is still within an acceptable range, so it is often used as the material of Skived Fin Heat Sink.

Thickness

The fin thickness of Skived Fin Heat Sink Parts usually depends on the specific application requirements and processing capabilities. Generally speaking, the thinner the thickness of the fin, the better the heat dissipation performance of the radiator. However, too thin fins are prone to deformation during processing, so it is necessary to consider the processing stability and strength of the fins while ensuring heat dissipation performance. In actual applications, the thickness of the fins is usually between 0.25mm and 2.0mm.

Detection Method

The inspection of Skived Fin Heat Sink Parts mainly includes two aspects: appearance inspection and performance inspection.

Appearance inspection: Visually inspect the appearance of the radiator to ensure that it has no obvious defects, such as scratches, deformations, stains, etc. In addition, it is also necessary to check whether the fins are arranged neatly and the gaps are consistent.

Performance inspection: Performance inspection focuses on the heat dissipation performance of the radiator. The heat dissipation effect of the radiator can be evaluated by thermal testing, that is, measuring the temperature change of the radiator under specific conditions to determine whether its heat dissipation capacity meets the design requirements.

Advantages

Skived Fin Heat Sink has the following significant advantages over other types of radiators:

High heat dissipation performance: Due to the consistent gaps and structures formed between the fins, the Skived Fin Heat Sink can provide a larger heat dissipation surface area, thereby improving the heat dissipation performance.

Low noise: Skived Fin Heat Sink usually does not require additional fans to enhance the heat dissipation effect, so its operating noise is relatively low.

High stability: Skived Fin Heat Sink is made by one-piece molding, which avoids the problems of reduced heat dissipation coefficient and increased conduction thermal resistance caused by welding, thereby improving the stability and reliability of the radiator.

Easy to process and customize: Skived Fin Heat Sink can be customized according to specific application requirements, such as changing the thickness, spacing and shape of the fins to meet different heat dissipation requirements.

Skived Fin Heat Sink is widely used in various occasions that require efficient heat dissipation due to its excellent heat dissipation performance and stability. The following are some typical application scenarios:

Automotive industry: Skived Fin Heat Sink is widely used in the heat dissipation system of automobile engines, transmissions and other components to ensure that these components can operate normally in high temperature environments.

Aerospace: In the aerospace field, Skived Fin Heat Sink is used to dissipate heat from key components such as aircraft engines and navigation systems to ensure flight safety.

Electronic equipment: With the continuous development of electronic equipment, its power density continues to increase, and the demand for heat dissipation is also increasing. Skived Fin Heat Sink is widely used in the heat dissipation system of electronic equipment such as computers, servers, and data centers due to its high heat dissipation performance and low noise characteristics.

Industrial equipment: In the industrial field, Skived Fin Heat Sink is used for heat dissipation of various high-power machines, such as frequency converters, inverters, power battery packs, etc. These devices generate a lot of heat during operation and require an efficient heat dissipation system to maintain normal operation.

New energy vehicles: Key components such as battery management systems and motor controllers in new energy vehicles also require efficient heat dissipation systems to maintain normal operation. Skived Fin Heat Sink is widely used in the heat dissipation systems of these components due to its excellent heat dissipation performance and stability.

As an efficient heat dissipation component, Skived Fin Heat Sink has been widely used in various fields. Its excellent heat dissipation performance, low noise, high stability and easy processing and customization make it an indispensable heat dissipation solution in modern industry. KingKa is a hardware processing and manufacturing supplier, welcome to contact us.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018