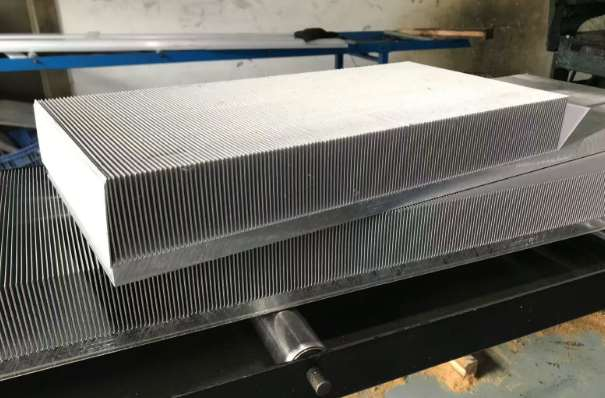

Our Skived Fin Heat Sink is an advanced thermal management solution designed for demanding high-power LED, IGBT, and TEC modules. By precisely skiving high-conductivity metals such as aluminum (AL 1060, AL 6063-T4) or Copper C1100, thin, dense fins are formed directly from the base metal. This one-piece molding technology eliminates thermal resistance caused by welding or bonding, improving overall heat dissipation efficiency.

As a professional Skived Fin heat sink Manufacturer, we provide standard and fully customizable solutions, including Skived Fin Heat Sink with Heat Pipe and Skived Fin Heat Sink Custom Size options, ensuring optimal performance for electronics, industrial automation, automotive, and renewable energy applications.

Superior Thermal Performance – The dense fin arrangement maximizes the heat transfer surface area, efficiently dissipating heat through natural convection or forced air, keeping components within safe operating temperatures.

One-Piece Molding Construction – Avoids issues associated with extrusion, epoxy bonding, or brazing, ensuring stable mechanical strength and improved thermal conductivity.

High Structural Stability – Made from robust metals, the Skived Fin Heat Sink can withstand thermal cycling, vibration, and mechanical stress without deformation.

Customizable Design – Dimensions, fin height, thickness, spacing, and base shape can all be tailored to meet specific application requirements.

Flexible Material Selection – AL 1060, AL 6063-T4, and Copper C1100 are selectable based on thermal and mechanical needs.

Precision Manufacturing – Each unit undergoes CNC Machining, fin cutting, base reshaping, and surface treatment (anodizing or other finishes), ensuring consistent quality and long-term reliability.

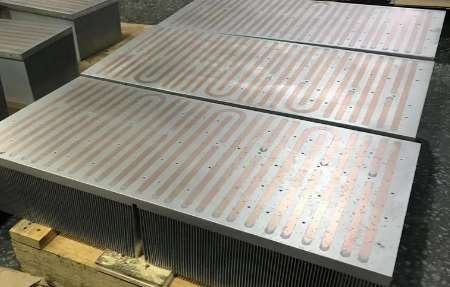

Integration with Heat Pipes – Combines Skived Fin Heat Sink with Heat Pipe technology for enhanced performance in high-density or compact applications.

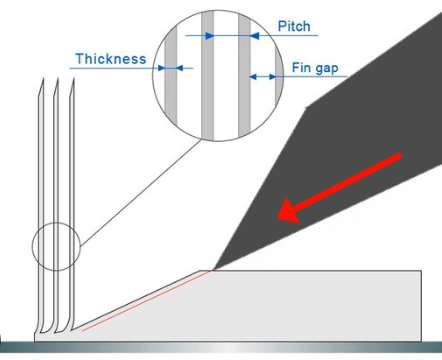

| Parameter | Aluminum | Copper (C1100) |

|---|---|---|

| Max Processing Width | 700mm | 700mm |

| Max Processing Height | 120mm | N/A |

| Max Fin Thickness | 2.0mm | 1.0mm |

| Min Fin Thickness | 0.5mm | 0.05mm |

| Max Fin Gap | 5.5 × Fin Thickness | 5.5 × Fin Thickness |

| Min Fin Gap | 0.5mm | 0.05mm |

These parameters allow high fin density and optimized thermal transfer, balancing manufacturability, mechanical strength, and cooling efficiency.

Extrusion Plate Hardening – Base metal is heat-treated for consistent hardness and stability.

Skived Fin Cutting – Thin, uniform fins are precisely cut from the base material.

Fin Height Adjustment & Base Reshaping – Corrects warping and ensures flatness of the heat sink base.

CNC Machining – Burr removal and preparation for surface treatment.

Surface Treatment – Anodizing or alternative finishes improve corrosion resistance and thermal performance.

Skived Fin Technology Advantages:

Enables high-density fin structures for extreme cooling requirements.

Reduces manufacturing complexity compared to bonded or brazed fin solutions.

Provides cost-effective molds with higher efficiency than traditional extrusion-based heat sinks.

High-Power LED Cooling – Streetlights, stadium lighting, industrial high-bay systems

IGBT Module Thermal Management – Solar inverters, EV power electronics, motor drives

TEC Module Applications – Precision cooling in laser systems, medical devices, and electronics

AI & Data Center Servers – High-performance computing and high-density server racks

Laser Equipment – Diode modules requiring consistent thermal control

Medical Equipment – MRI, imaging devices, and diagnostic machinery

Automotive PTC Heating Tube Cooling – EV and hybrid vehicle thermal management

Industrial Automation & Communication Equipment – Controllers, sensors, and telecom modules

Efficient Heat Transfer – Rapidly moves heat away from sensitive components.

Temperature Control – Maintains stable operating conditions, preventing overheating.

Extended System Reliability – Reduces thermal stress and prolongs the lifespan of electronic components.

Optimized Performance – Enhances overall system efficiency and operational stability.

Tailored Thermal Solutions – Supports complex layouts, customized fin arrangements, and integration with other cooling systems.

Regular Cleaning – Remove dust with a soft brush or dry cloth; avoid water or chemical cleaners.

Performance Monitoring – Inspect airflow, fan operation, and thermal interface materials.

Avoid Prolonged High Loads – Excessive heat can accelerate wear or damage the heat sink.

Professional Maintenance – Damaged heat sinks should be repaired or replaced by professionals.

Proper Installation – Ensure tight contact with the heat source and unobstructed airflow.

Minimize Vibration & Shock – To maintain structural integrity and thermal performance.

As a leading Skived Fin Heat Sink Manufacturer, we provide:

Custom Skived Fin Heat Sink with Heat Pipe solutions for high-power applications

Skived Fin Cooling Modules designed for specific device footprints and airflow requirements

Proven high-precision manufacturing and QC processes for industrial, automotive, and electronics applications

Download our product catalog for full specifications, sizes, and customization options of![]() Skived Fin Heat Sink, High Performance Skived Fin Heat Sink, Skived Fin Thermal Solution, and Skived Fin Cooling Module.

Skived Fin Heat Sink, High Performance Skived Fin Heat Sink, Skived Fin Thermal Solution, and Skived Fin Cooling Module.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018