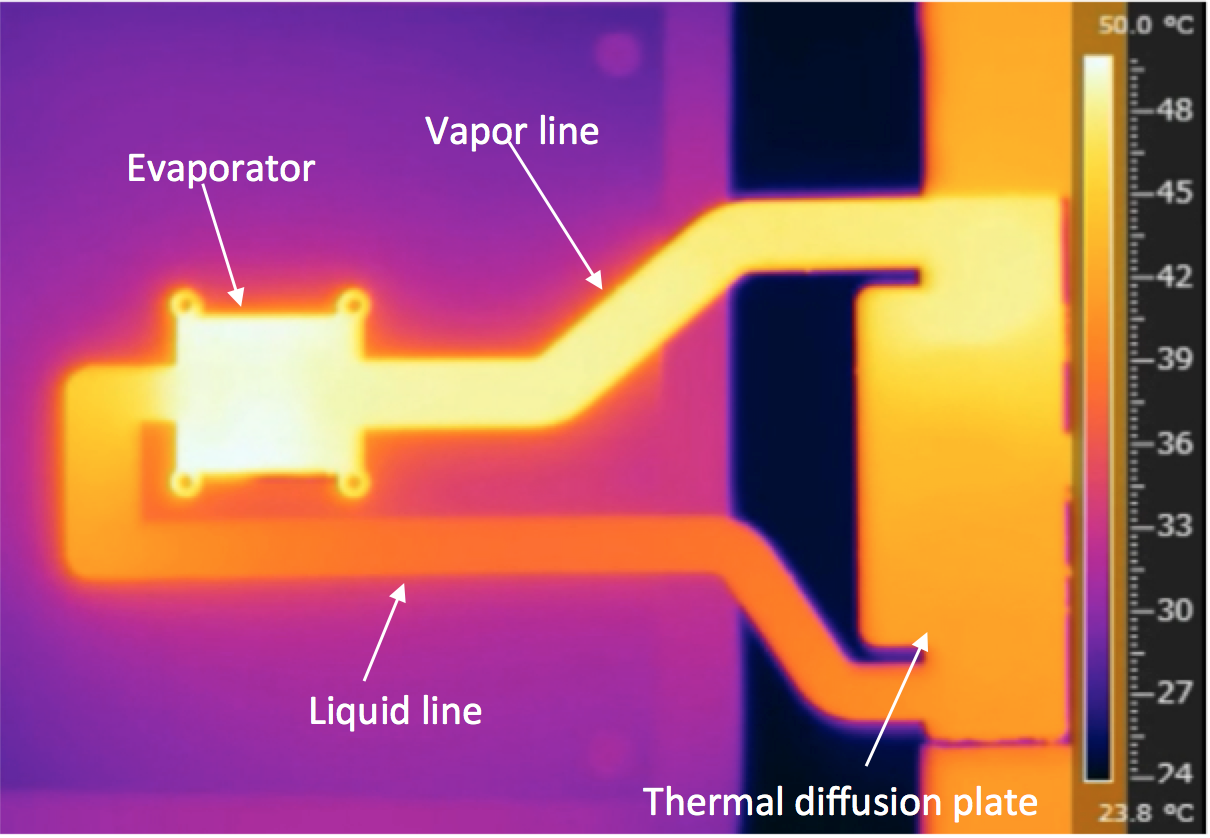

Heat Pipe Thermal Module Parts are key components that make up the heat pipe cooling module. The heat pipe cooling module achieves effective heat dissipation by utilizing the efficient heat transfer performance of the heat pipe to quickly conduct heat from the heating end to the cooling end. The tightness is ±0.01mm~±0.05mm.

Main materials:

Copper: Copper is one of the commonly used materials in heat pipe cooling module components. It has good thermal conductivity and ductility, which can ensure the rapid transfer of heat in the heat pipe. In addition, copper has high strength and corrosion resistance, which is suitable for various harsh working environments.

Aluminum: Aluminum is another commonly used heat pipe cooling module component material. Compared with copper, aluminum has a lower density, but its thermal conductivity is also quite good. In addition, aluminum has excellent processing performance and corrosion resistance, which can meet the needs of heat pipe cooling module components of different shapes and sizes.

Material advantages:

High thermal conductivity: Both copper and aluminum have excellent thermal conductivity and can quickly transfer heat from the heating end to the cooling end.

Good processing performance: Both materials are easy to process and form, which can meet the needs of heat pipe cooling module components of different shapes and sizes.

Corrosion resistance: Both copper and aluminum have good corrosion resistance and can maintain stable performance in harsh working environments.

Thickness and tightness detection

Thickness:

The thickness of heat pipe cooling module components is usually determined according to specific application scenarios and needs. Generally speaking, in order to maintain the shape and strength of the heat pipe while ensuring effective heat transfer, the component needs to have a certain thickness. However, with the development of technology, heat pipe cooling module components are moving towards thinner and lighter directions. For example, heat pipe cooling module components in mobile devices such as mobile phones and tablets need to be as thin as possible to fit the limited internal space.

The specific thickness value may vary for different heat pipe cooling module components. Some high-end heat pipe cooling module components may adopt a thinner design to improve heat dissipation efficiency and reduce weight.

Tightness detection:

Tightness is one of the important indicators of the performance of heat pipe cooling module components. It is related to the flow of working fluid inside the heat pipe and the efficiency of heat transfer. Therefore, the components need to be tested for tightness during the manufacturing process.

Commonly used tightness detection tools include vernier calipers, micrometers, microscopes, etc. These tools can accurately measure the size and shape of the components to determine whether their tightness meets the requirements.

Surface treatment

The surface treatment of heat pipe cooling module components is of great significance to improve their performance and service life. Common surface treatment methods include anodizing, sandblasting and electroplating.

Anodizing: Anodizing is a treatment method that forms an oxide film on the metal surface by electrochemical methods. This oxide film can improve the corrosion resistance and hardness of the metal, while increasing its aesthetics.

Sandblasting: Sandblasting is a method of cleaning and roughening the metal surface by high-pressure spraying of abrasives such as sand. It can remove dirt and oxide layers on the metal surface, while increasing the surface roughness and improving the adhesion of the coating or plating.

Electroplating: Electroplating is a method of plating a layer of other metals or alloys on the metal surface. This coating can improve the corrosion resistance, hardness and aesthetics of the metal. At the same time, electroplating can also change the color of the metal surface to meet different aesthetic needs.

Heat pipe cooling module components are widely used in various fields due to their excellent heat dissipation performance and stability:

Aerospace: In the aerospace field, heat pipe cooling module components are used to control the temperature of aircraft to ensure their stable operation.

Electronics industry: In the electronics industry, heat pipe cooling module components are used in heat sinks, radiators and other components to effectively reduce the temperature of electronic equipment.

Automotive industry: In the automotive industry, heat pipe cooling module parts are used in engine cooling systems, air conditioning systems and other components to improve the operating efficiency and comfort of the car.

Chemical and metallurgical fields: In the chemical and metallurgical fields, heat pipe cooling module parts are used in various heat exchangers to achieve efficient heat transfer and recovery.

KingKa is a custom supply wholesaler of Heat Pipe Thermal Module Parts. It has passed ISO, CE and other international quality certifications, provides a variety of material options such as copper and aluminum, and adopts surface treatment processes such as anodizing, sandblasting, and electroplating. Supports customization according to drawings, and each part is strictly tested to ensure compliance with international standards, providing customers with high-quality heat pipe cooling module parts.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018