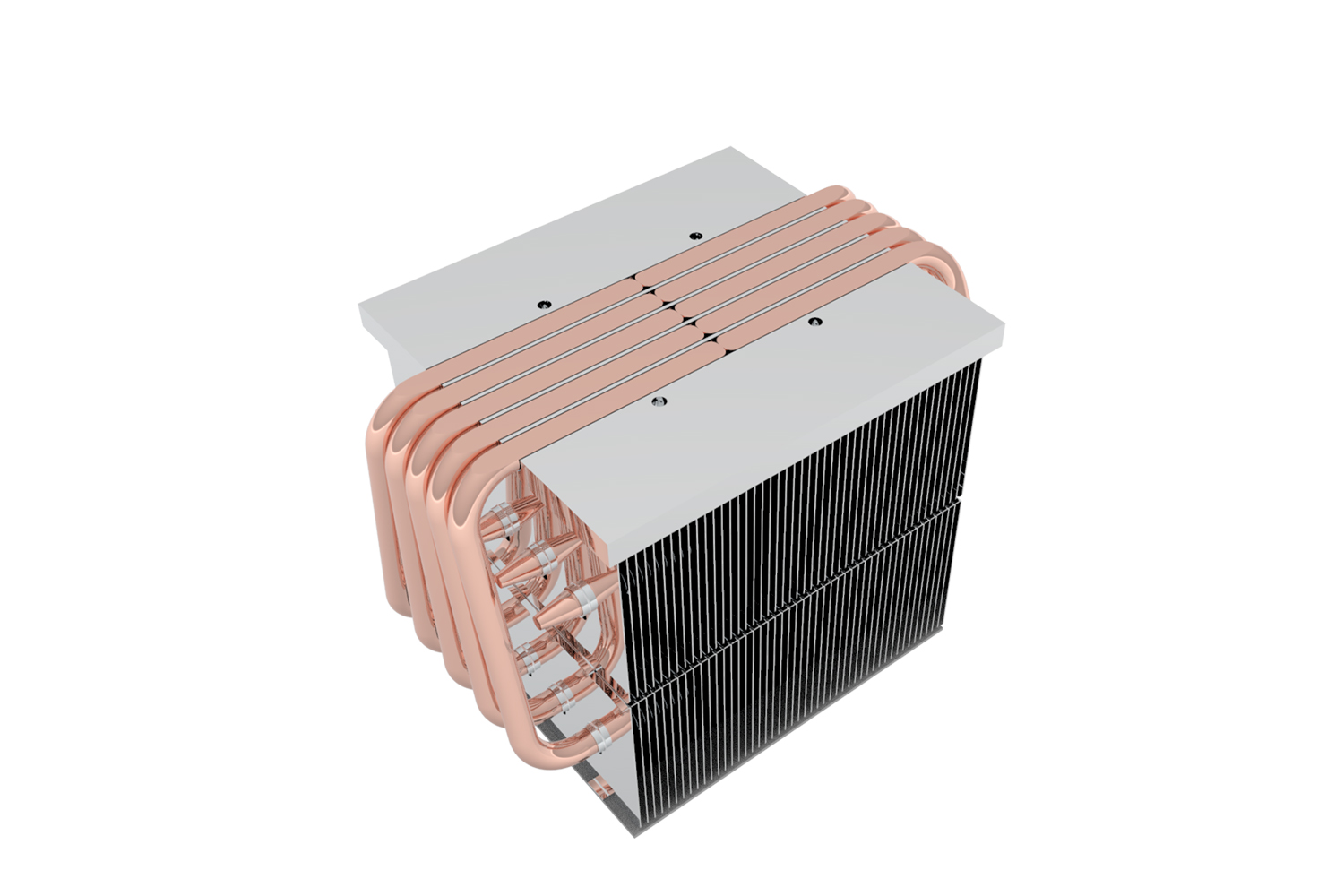

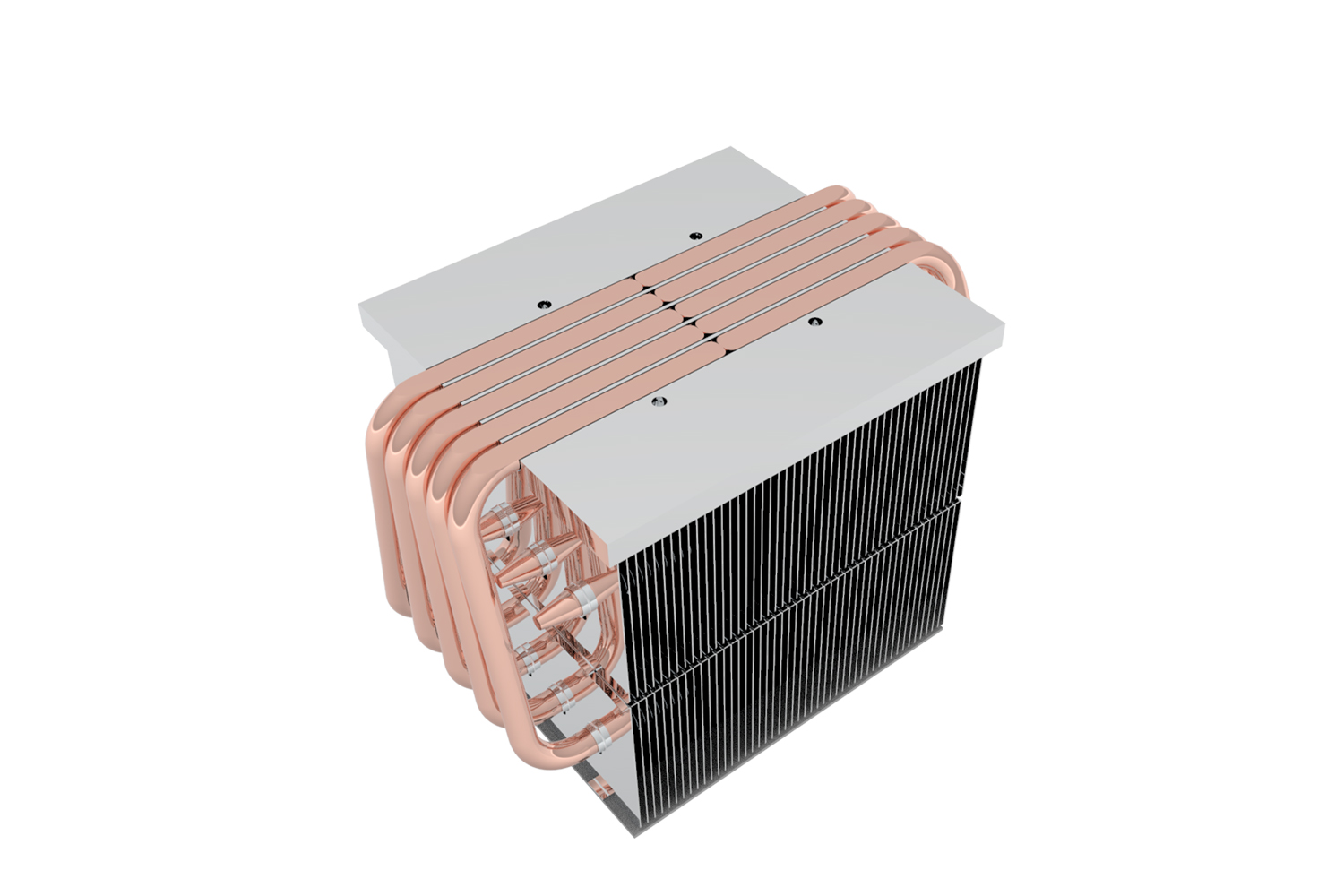

As electronic devices become increasingly powerful, efficient heat dissipation is critical to maintaining performance, reliability, and longevity. The heat sink With Heat Pipe, also known as a Heat Pipe Heat Sink, is an advanced thermal management solution designed for high-power electronics, including computers, LED lighting, servers, automotive electronics, and industrial equipment.

By combining traditional Heat Sinks with integrated Heat Pipes, this technology effectively transfers heat from the source to the Heat Sink surface, dissipating it into the surrounding environment through convection and radiation.

Heat Pipes are typically made of high-conductivity materials like copper or aluminum. Inside each pipe is a working fluid that absorbs heat at the evaporation end, moves it through the pipe via vaporization, and releases it at the condensation end. The fluid then returns through a capillary structure, creating a highly efficient heat transfer cycle.

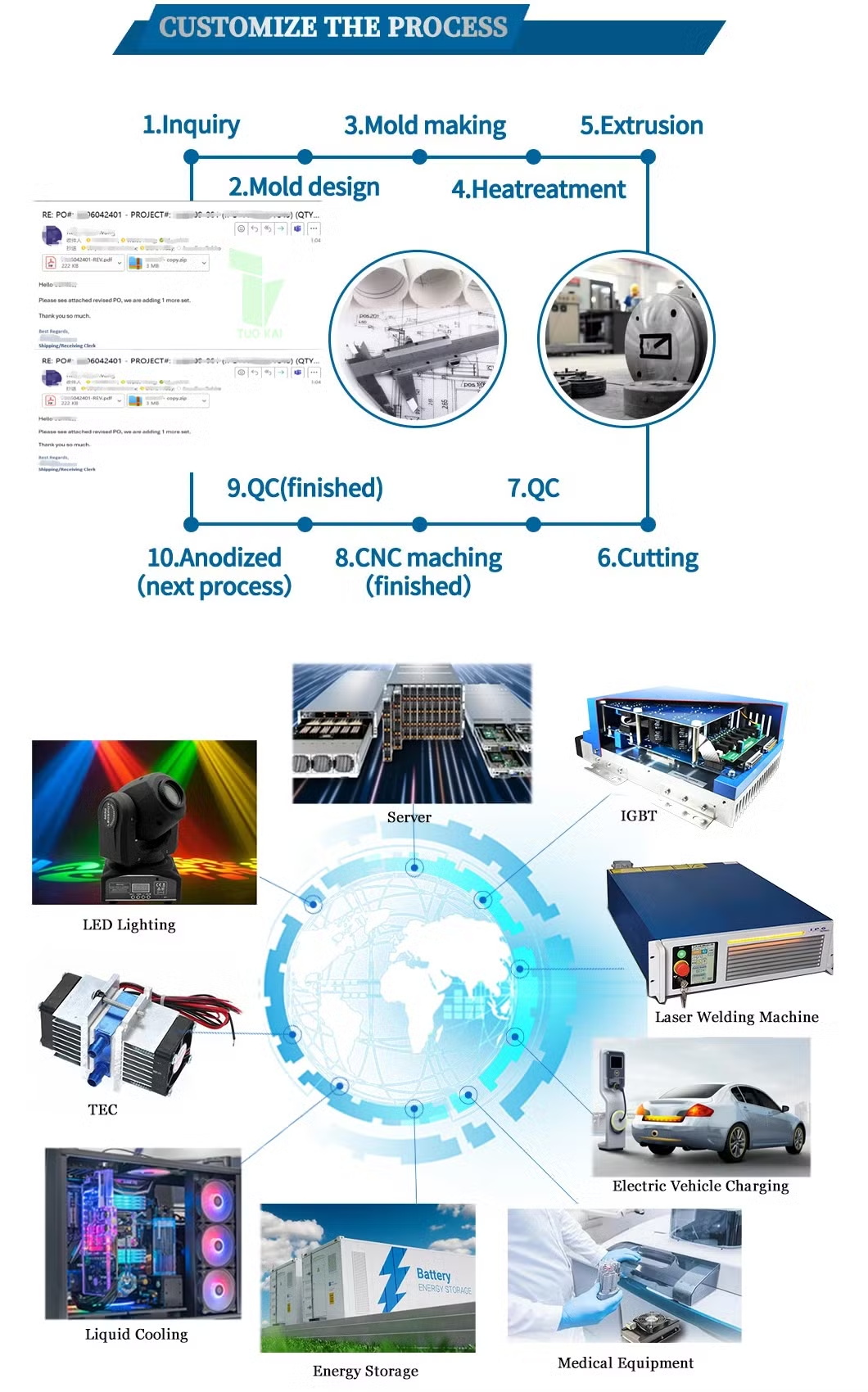

Manufacturing Process of Heat Pipes:

Precision copper/aluminum tube processing

Inner wall coating with working fluid

Pressurized sealing and vacuum injection

Rigorous testing to ensure consistent evaporation and condensation efficiency

The Heat Sink component is usually crafted from aluminum alloy and features multiple fins designed through CNC milling or stamping to maximize surface area for heat dissipation.

Surface treatments enhance performance:

Anodizing: Improves corrosion resistance, hardness, and thermal conductivity

Spraying: Applies coatings that enhance thermal transfer and protect against corrosion

Special Coatings: Materials like graphene or carbon nanotubes improve conductivity

Metal Plating: Nickel or silver plating increases oxidation resistance and durability

Connection methods include welding or hot pressing, ensuring direct thermal contact for optimal heat transfer. This integration is critical for high-performance Heat Pipe Heat Sinks, enabling them to manage high thermal loads efficiently.

Heat Pipe Dimensions: 6–12mm in diameter, customizable lengths, ±0.1mm tolerance

Fin Spacing: Typically 1–5mm, with ±0.1mm precision to maximize airflow and cooling efficiency

Thermal Resistance: 0.2°C/W to 2°C/W depending on design

Thermal Conductivity: Aluminum alloy 200–220 W/m·K; copper up to 380 W/m·K

Electronic Devices: CPUs, GPUs, game consoles, routers, and other high-power components benefit from enhanced thermal management to prevent throttling and extend hardware life.

LED Lighting: Heat Pipe Heat Sinks reduce operating temperatures for high-power LEDs, prolonging lifespan and maintaining light output efficiency.

Servers and Data Centers: High-density server racks generate significant heat. Heat Pipe Heat Sinks prevent overheating, maintain reliability, and enable higher server density.

Automotive Electronics: Used in battery management systems, engine control units, and other electronic modules in electric, hybrid, and traditional vehicles.

Industrial Equipment: Automation machinery, medical devices, and communication systems rely on efficient Heat Pipe Heat Sinks to operate safely under heavy load.

To ensure optimal performance:

Regular Cleaning: Remove dust from fins using compressed air or a soft brush

Check Heat Pipe Connections: Inspect welding or hot-pressed joints for integrity

Avoid Excessive Impact: Prevent mechanical damage to the heat pipe

Ambient Temperature Control: Maintain recommended operating temperatures to prevent overload

Leak Prevention: Protect the heat pipe from punctures or sharp objects

Ensure correct orientation: evaporation end faces the heat source, condensation end faces the fins

Operate within the manufacturer’s recommended temperature range and load limits

Select materials based on the environment, such as nickel-plated aluminum for corrosive conditions

Choose products with proper quality certification for long-term reliability

The Heat Sink With Heat Pipe provides:

Superior Thermal Performance: Efficiently moves heat away from high-power components

Extended Equipment Life: Maintains stable temperatures, reducing wear

Compact Design: Integrates into high-density electronic assemblies

Versatile Application: Ideal for computers, servers, LED lighting, automotive, and industrial equipment

With the growing thermal requirements of modern electronics, Heat Pipe Heat Sinks are becoming essential in high-performance thermal management. By combining precision engineering, advanced materials, and innovative surface treatments, these heat sinks deliver reliable, long-term cooling solutions for demanding applications.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018