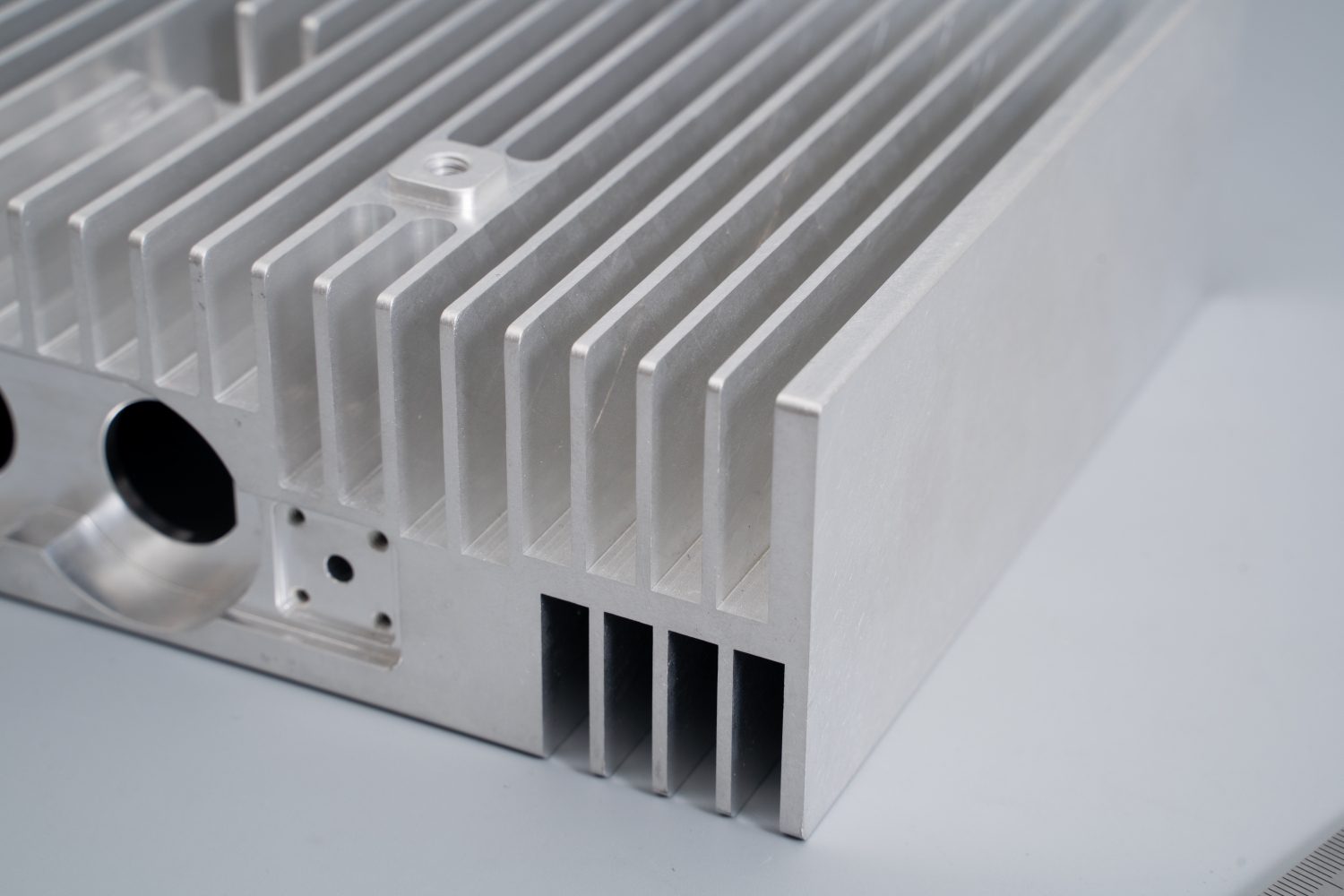

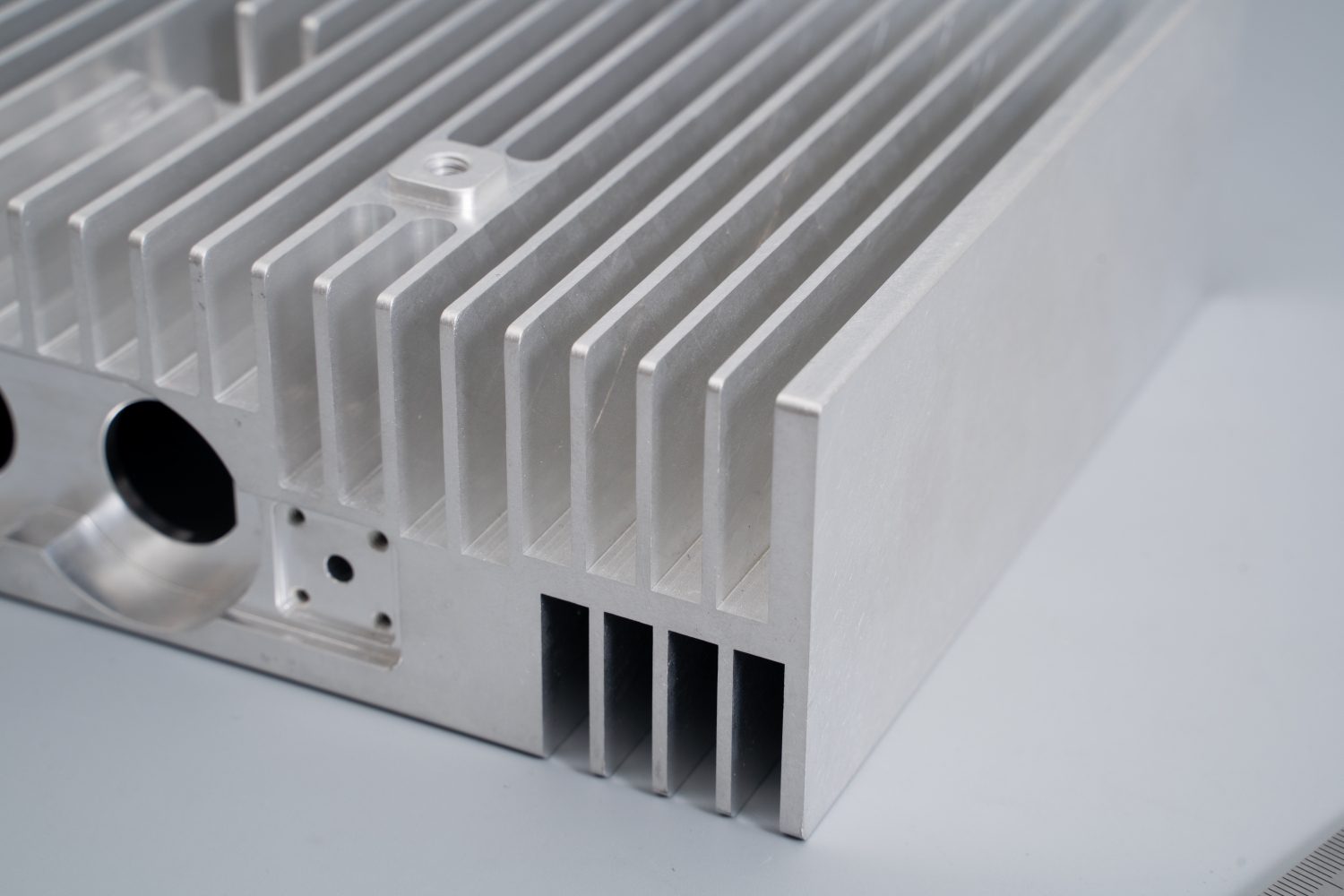

Aluminum Extrusion Heat Sink is a heat sink made by aluminum extrusion process. It uses the high thermal conductivity of aluminum and is extruded by a specific die to form a heat dissipation structure with an efficient heat dissipation area. Aluminum extrusion heat sinks have been widely used in many fields due to their low cost, convenient processing, good heat dissipation effect and other advantages.

Function

The main function of aluminum extrusion heat sink is to absorb and dissipate heat to ensure that related equipment operates at normal operating temperature. In the field of computer hardware, especially in electronic equipment and systems that handle high-speed computing, the role of aluminum extrusion heat sink is particularly prominent. It can effectively reduce the temperature of key components such as CPU and graphics card to prevent performance degradation or damage caused by overheating. In addition, in the automotive industry, power electronics field, aerospace field, etc., aluminum extrusion heat sinks also play an important role to ensure the normal operation and performance of various key equipment.

The manufacturing process of aluminum extrusion heat sink mainly includes the following steps:

Aluminum ingot heating: Heat the aluminum ingot to about 520~540℃ to reach the solid-liquid critical point for easy extrusion molding.

Extrusion molding: Under high temperature and high pressure environment, the aluminum liquid is extruded through a die. The design of the mold determines the shape and heat dissipation area of the radiator.

Subsequent processing: The extruded radiator is subjected to subsequent processing such as cutting, grinding, and polishing to improve its heat dissipation effect and aesthetics.

Quality i

nspection: The finished product is quality inspected to ensure that it meets relevant standards and requirements.

Precision

The precision of the aluminum extruded radiator mainly depends on the design of the mold, the control of the extrusion process, and the quality of subsequent processing. High-quality molds and precise extrusion processes can ensure that the radiator has a uniform heat dissipation area and precise dimensions. In addition, the quality of subsequent processing also directly affects the heat dissipation effect and aesthetics of the radiator. Therefore, the quality of each link needs to be strictly controlled during the manufacturing process to ensure the precision and heat dissipation effect of the radiator.

Features

High thermal conductivity: Aluminum is an excellent thermal conductive material, and its thermal conductivity is second only to silver and copper. The radiator manufactured by the aluminum extrusion process has an efficient heat dissipation area and excellent thermal conductivity.

Low cost: The aluminum extrusion process is relatively simple, the equipment cost is low, and the price of aluminum is relatively cheap, so the cost of aluminum extruded radiators is low.

Easy processing: Aluminum is easy to process and can be processed by extrusion, cutting, grinding and other processes, which is convenient for manufacturing radiators of various shapes.

Strong corrosion resistance: Aluminum has good corrosion resistance and can be used for a long time in harsh environments without rusting or corrosion.

Advantages

Efficient heat dissipation: Aluminum extruded radiators have efficient heat dissipation area and excellent thermal conductivity, which can quickly dissipate heat and ensure that the equipment operates at normal operating temperature.

Energy saving and environmental protection: Because aluminum extruded radiators have efficient heat dissipation effects, they can reduce the energy consumption and carbon emissions of equipment, meeting the requirements of energy saving and environmental protection.

Long service life: Aluminum has good corrosion resistance and mechanical strength, and can be used for a long time without damage or deformation.

Easy maintenance: The structure of aluminum extruded radiators is simple, easy to disassemble and clean, and convenient for users to maintain and maintain.

Aluminum extruded radiators have been widely used in many fields, mainly including the following aspects:

Computer hardware: In the field of computer hardware, aluminum extruded radiators are widely used for heat dissipation of key components such as CPUs and graphics cards. It can effectively reduce the temperature of these components and improve the stability and performance of the computer.

Automotive industry: In the automotive industry, aluminum extruded radiators are used to dissipate heat for automotive engines, batteries and other components. It can effectively reduce the temperature of these components and improve the reliability and safety of the car.

Power electronics: In the field of power electronics, aluminum extruded radiators are used to dissipate heat for power electronic equipment, inverters and other components. It can effectively reduce the temperature of these devices and prevent performance degradation or damage caused by overheating.

Aerospace: In the field of aerospace, aluminum extruded radiators are used to dissipate heat for spacecraft such as aircraft and satellites. It can effectively reduce the temperature of spacecraft and ensure its normal operation in extreme environments.

In addition, aluminum extruded radiators are also widely used in communication equipment, medical equipment, industrial control equipment and other fields. With the continuous development of science and technology, the application field of aluminum extruded radiators will continue to expand.

The development trend of aluminum extruded radiators mainly presents the following aspects:

Efficiency: By improving mold design, optimizing extrusion process and other methods, the heat dissipation efficiency and heat dissipation area of the radiator are improved to meet higher requirements for heat dissipation.

Lightweight: Under the premise of ensuring the heat dissipation effect, the weight of the radiator is reduced by adopting new materials and optimizing structural design to improve the portability and energy efficiency of the equipment.

Intelligence: Integrate intelligent components such as sensors and controllers into the radiator to realize intelligent control and adjustment of the radiator, improve the heat dissipation effect and the stability of the equipment.

Environmental protection: Use environmentally friendly materials and processes to manufacture radiators, reduce the impact and pollution on the environment, and meet the requirements of sustainable development.

Aluminum extruded radiators, as a high-efficiency, low-cost, and easy-to-process heat dissipation device, have been widely used in many fields. With the continuous development of science and technology, aluminum extruded radiators will continue to develop in the direction of high efficiency, lightweight, intelligence and environmental protection, providing more reliable guarantees for the normal operation and performance of related equipment.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018