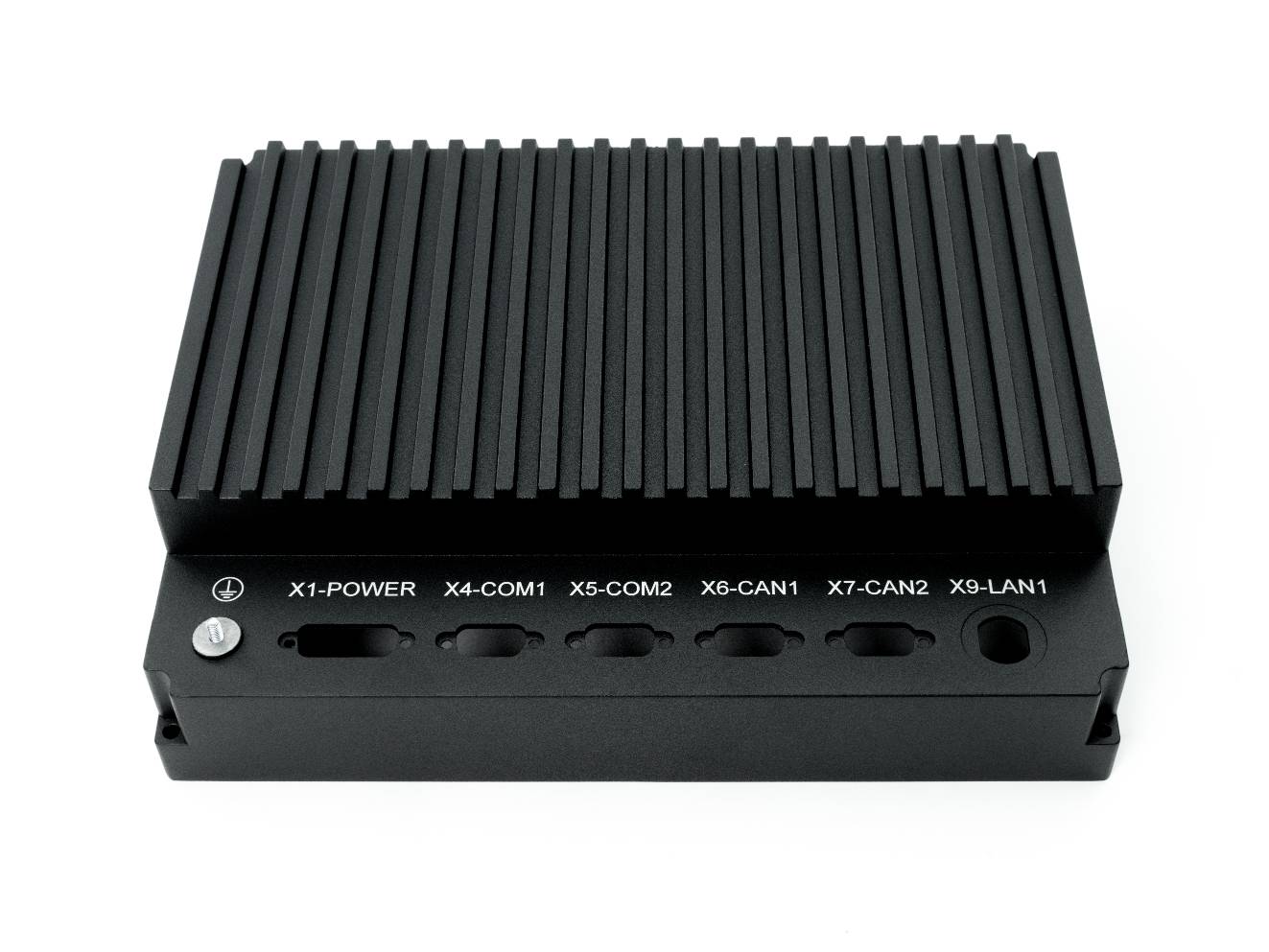

Die Casting Enclosure is a shell component manufactured through die-casting technology. Die casting is a molding method that injects molten metal into a mold under high pressure, which can produce metal parts with complex shapes and high precision. Die cast casings are widely used in electronic devices, automotive components, mechanical equipment and other fields as important components for protecting internal components, providing structural support and aesthetic appearance.

2、 Characteristics

High precision and complexity: Die casting technology can manufacture shell components with complex shapes and precise dimensions, meeting the precision and complexity requirements of various application scenarios.

High strength and corrosion resistance: Die cast shells are usually made of high-quality materials such as aluminum alloy and zinc alloy, which have high strength and corrosion resistance, and can maintain stable performance in harsh environments.

Good heat dissipation: The design of die-casting shells usually considers heat dissipation requirements. By optimizing the structure and material selection, it can effectively dissipate the heat generated by internal components and ensure the normal operation of the equipment.

Lightweight: The application of lightweight materials such as aluminum alloy enables the die-casting shell to achieve lightweight design while maintaining high performance, which is beneficial for reducing the overall weight and energy consumption of the equipment.

Beautiful appearance: The surface treatment process of the die-casting shell is diverse, such as sandblasting, polishing, electroplating, etc., which can present rich texture and color, enhance the beauty and market competitiveness of the product.

3、 Function

Protecting internal components: The die-casting shell serves as the external protective layer of the equipment, effectively preventing damage to internal components from external factors such as dust, moisture, and vibration, and extending the service life of the equipment.

Provide structural support: The die-casting shell has high strength and rigidity, which can provide stable structural support for the equipment and ensure its normal operation in complex environments.

Heat dissipation function: By optimizing the shell structure and material selection, the die-casting shell can effectively dissipate the heat generated by internal components, preventing performance degradation or damage caused by overheating.

Aesthetics and Identification: The appearance design of the die-casting shell can enhance the product's aesthetics and market competitiveness, while the identification and labels on the shell can also provide product information and usage instructions.

4、 Maintenance and upkeep

Regular cleaning: Regularly use a soft cloth or tissue dipped in an appropriate amount of cleaning agent to wipe the surface of the die-casting shell, removing dust and dirt. Avoid using metal brushes or rough fabrics to avoid scratching the surface of the casing. For stubborn stains, professional cleaning agents or solvents can be used for cleaning, but it is important to pay attention to the dilution ratio and usage method to avoid corrosion or damage to the shell.

Check fasteners: Regularly inspect the fasteners on the die-casting shell, such as screws, nuts, etc., to ensure that they are securely fastened. If loose or damaged fasteners are found, they should be replaced or repaired in a timely manner to avoid safety hazards caused by loose or deformed shells.

Avoid collision and scratching: When using and storing die cast shells, avoid contact with hard or sharp objects to prevent damage to the shell caused by collision or scratching. At the same time, it is also necessary to avoid pressing heavy objects on the shell to prevent deformation or rupture of the shell.

Pay attention to the usage environment: Although die-casting shells have high corrosion resistance and weather resistance, they may still be affected in extreme environments. Therefore, when using equipment with die-casting shells, attention should be paid to the usage environment and avoid prolonged exposure to harsh environments such as high temperature, humidity, and corrosion.

5、 Precautions

Safety first: When disassembling and cleaning the die-casting shell, be sure to disconnect the power supply of the equipment and wait for a few minutes to ensure that the internal capacitors discharge, avoiding electric shock or damage to the equipment. At the same time, personal protection should be taken into account during the operation to avoid injury.

Choosing the appropriate cleaning agent: Using the appropriate cleaning agent can effectively remove stains and dirt from the surface of the die-casting shell, but it is important to avoid using highly corrosive cleaning agents or solvents to prevent damage to the shell. When choosing a cleaning agent, you can refer to the requirements of the shell material and surface treatment process for selection.

Professional maintenance: If the die-casting shell is severely damaged or cannot be repaired, seek the help of professional maintenance personnel. Avoid disassembling or repairing on your own, which may cause greater losses or safety hazards.

Pay attention to the compatibility of the casing: When replacing or upgrading the die-casting casing, pay attention to the compatibility between the casing and the internal components of the equipment. Ensure that the new casing can fully cover and protect the internal components without affecting the normal operation and heat dissipation performance of the device.

Storage and Preservation: For temporarily unused die-casting shells, they should be stored and preserved properly. Avoid prolonged exposure to direct sunlight or humid environments to prevent aging, deformation, or corrosion of the casing. At the same time, it is also necessary to avoid contact between the shell and flammable and explosive materials to prevent fire or explosion accidents.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018