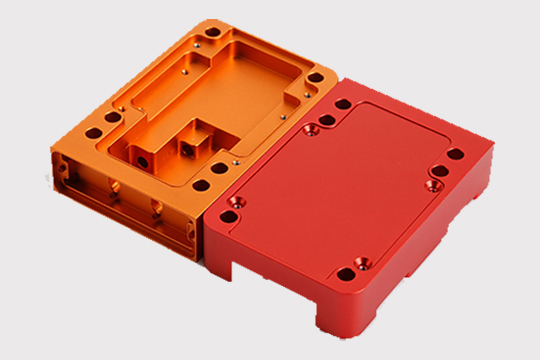

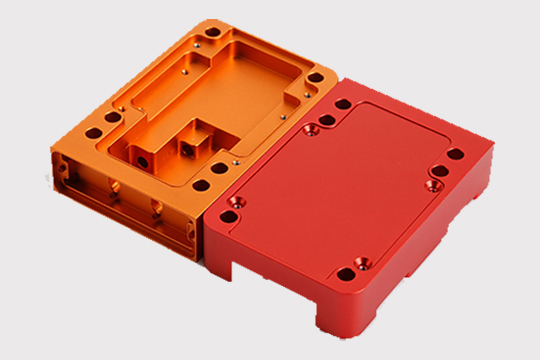

Our CNC milled parts are the epitome of precision engineering, utilizing advanced Computer Numerical Control (CNC) milling technology to achieve unparalleled accuracy down to the micrometer level. Crafted from high-quality materials, these parts undergo rigorous quality control measures from material selection to final inspection, ensuring durability and long-lasting performance. We use only the finest raw materials to cater to the unique demands of your project.

Our in-house design team collaborates closely with clients to understand their needs, translating complex designs into reality through advanced CAD/CAM software. This enables us to offer highly customized solutions, ranging from one-off prototypes to large-scale production runs.

Product Parameters:

Material: Options Aluminum, Stainless Steel, Brass, ABS Plastic, etc

Surface Finish: Anodizing, Powder Coating, Polishing, Plating (as required)

Tolerances: ±0.01mm to ±0.05mm (depending on part complexity and material)

Dimension Range: Customized to any specified size

Package : Plastic bags+ Cartons/Cartons+Pallet/wooden box

Lead Time: Prototypes within 7-14 days, Mass Production 2-4 weeks

Product Features & Benefits:

Precision Machining: Guarantees tight tolerances and smooth surfaces

Material Versatility: Supports a wide range of materials for diverse applications

Custom Design Capabilities: Fully customizable to match your exact specifications

Durability: High-quality materials ensure long-term performance and reliability

Quick Turnaround Time: Fast prototyping and efficient production processes

Product Application Scenarios:

Aerospace & Defense

Automotive Industry

Medical Equipment

Electronics & Semiconductors

Robotics & Automation

Precision Instrumentation

Heavy Machinery

Product FAQs:

Q: Can I customize the material and dimensions of the CNC milled parts?

Absolutely! We offer full customization services, including material selection and dimensional specifications.

Q: What is the minimum order quantity for CNC milled parts?

Our minimum order quantity depends on the part's complexity and chosen material. We cater to both one-off prototypes and large-scale production runs.

Q: How do you ensure the quality of CNC milled parts?

We adhere strictly to quality control protocols throughout the manufacturing process, from material sourcing to final inspection. Each part is meticulously checked using precision measurement tools to ensure it meets or exceeds industry standards.

Q: How long does it take to produce custom CNC milled parts?

Lead times vary based on part complexity, material, and production volume. Typically, prototypes can be completed within 7-14 days, while mass orders may take 2-4 weeks.

Q: Do you offer post-processing services like anodizing or powder coating?

Yes, we offer a range of post-processing services to enhance the appearance and functionality of CNC milled parts, including anodizing, powder coating, polishing, and plating.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018