With the rapid growth of high-power electronics, electric vehicles, and advanced industrial systems, effective heat dissipation is no longer optional—it is essential. The Vacuum Brazing Liquid Cold Plate provides a cutting-edge solution for efficient thermal management, combining high thermal conductivity, structural integrity, and long-term reliability. Designed for demanding applications, our brazed liquid cold plates are engineered to meet the highest standards of performance.

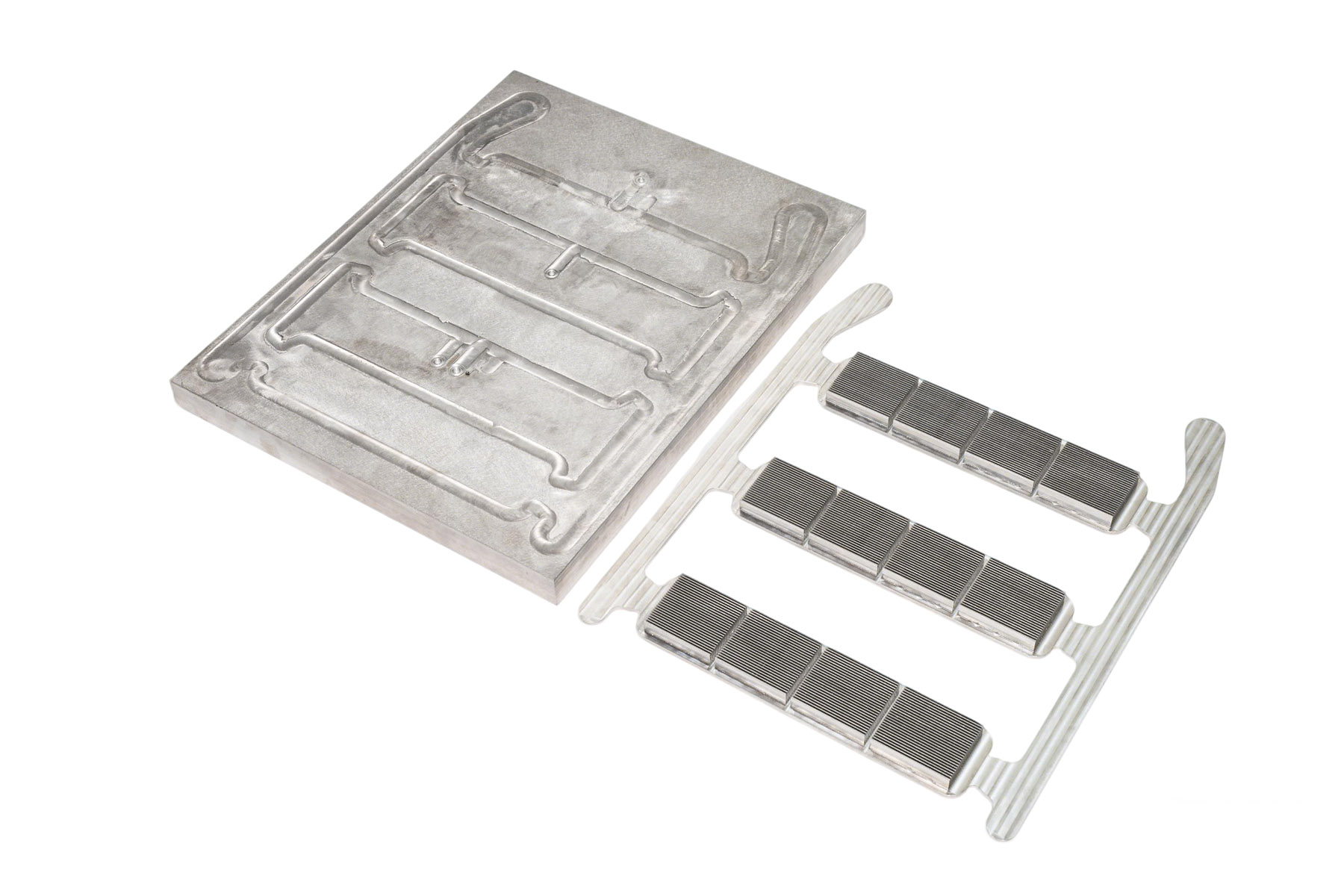

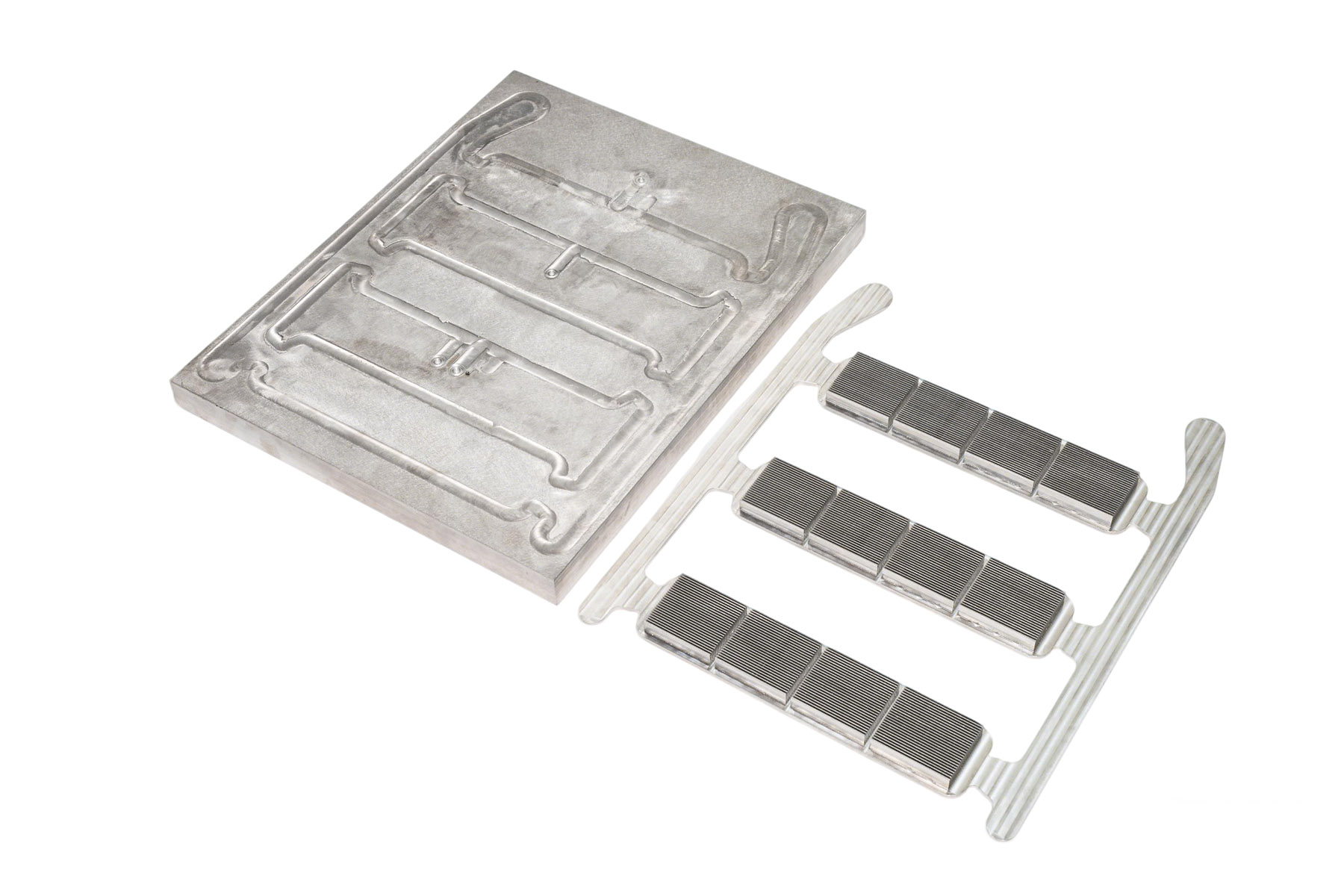

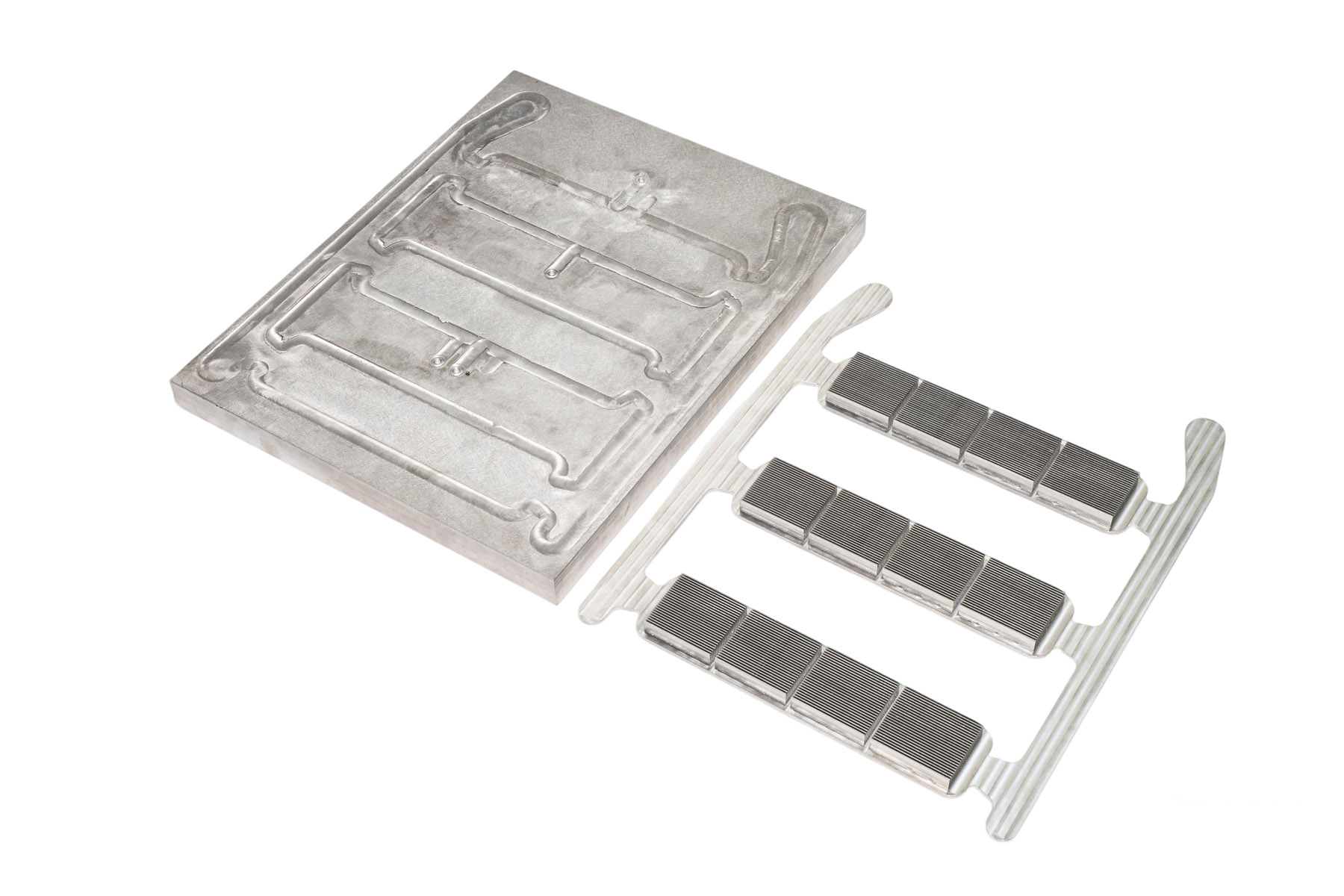

A vacuum brazing cold plate is a type of liquid cold plate produced using advanced vacuum brazing technology. Unlike traditional soldering or mechanical assembly, vacuum brazing joins metal components—commonly aluminum or copper—under high temperature in a vacuum environment. The process allows the filler metal to form a metallurgical bond without oxidation, contamination, or voids.

Key characteristics of a brazed cold plate include:

Exceptional Thermal Conductivity: Minimal thermal resistance ensures heat is transferred efficiently from heat-generating components to the cooling fluid.

Leak-Free and Durable Construction: Vacuum brazing produces strong joints, eliminating the risk of leaks under high pressure or thermal cycling.

Uniform Heat Distribution: The brazed structure ensures consistent temperature across the plate surface, preventing hotspots.

Our liquid cooling plates are designed for high efficiency and long-term reliability. Key features include:

High-Performance Cold Plate Design: Optimized internal channels provide maximum heat transfer and pressure drop balance for high-performance cold plates.

Customizable Solutions: We offer custom liquid cold plate designs with flexible channel layouts, inlet/outlet configurations, and surface area options to suit your specific liquid cooled cold plate requirements.

Material Selection: Aluminum for lightweight applications, copper for maximum thermal conductivity, or hybrid designs to meet unique system requirements.

Compact and Space-Saving: Ideal for high-density electronics, EV battery modules, power semiconductors, and aerospace systems.

Corrosion and Leak Resistance: Seamless vacuum brazing ensures long-term durability and reliability even in harsh operating conditions.

Versatile Fluid Compatibility: Designed for water, glycol, dielectric fluids, and specialized coolants.

Understanding how liquid cold plates work is critical for system design:

The coolant flows through the internal channels of the liquid cold plates, absorbing heat directly from electronic or power components.

The heated fluid is transported to a heat exchanger, radiator, or chiller for dissipation.

Continuous circulation ensures stable operating temperatures, reducing thermal stress and improving component lifespan.

This cold plate liquid cooling system provides superior heat management compared to air cooling, particularly in high-density or high-heat-flux applications.

As a professional Vacuum Brazing Liquid Cold Plate manufacturer, we utilize precise and controlled processes:

Material Preparation: High-purity aluminum or copper plates are machined to form channels.

Assembly: Components are stacked and aligned with brazing foils or pastes.

Vacuum Brazing: The assembly is placed in a vacuum furnace, where heat causes the filler metal to flow and bond components.

Inspection & Testing: Each brazed liquid cold plate undergoes leak testing, dimensional verification, and thermal performance evaluation.

This rigorous process ensures superior quality and consistent performance for every liquid cooling plate we produce.

Our liquid cold plates are widely used across industries:

Data Centers & Servers: High-density servers and GPU clusters requiring efficient thermal management.

Electric Vehicles (EVs): Battery thermal management and power electronics cooling for extended lifespan and safety.

Power Modules & Semiconductors: IGBTs, MOSFETs, and high-current modules in industrial electronics.

Aerospace & Defense: Precision cooling for avionics, radar systems, and laser equipment.

Industrial Machinery: High-power lasers, robotic systems, and other thermal-critical devices.

Custom Liquid Cold Plate Solutions: We design custom liquid cold plates tailored to your thermal requirements, including complex geometries and multi-inlet/outlet configurations.

Reliable Performance: Our brazed liquid cold plates provide leak-free operation and superior thermal management under extreme conditions.

Expert Supplier: As a trusted Vacuum Brazing Liquid Cold Plate supplier, we offer engineering support, design consultation, and scalable manufacturing for OEMs and bulk orders.

Cost-Effective: Our manufacturing expertise and optimized designs ensure competitive pricing without compromising quality.

A vacuum brazing liquid cold plate is a type of liquid cold plate manufactured using vacuum brazing technology. During this process, metal components (commonly copper or aluminum) are joined under high temperature in a vacuum environment, forming a brazed cold plate with high thermal conductivity, leak-free joints, and superior durability.

Liquid cold plates operate by circulating coolant (water, glycol, or dielectric fluids) through internal channels. The coolant absorbs heat from electronic components or power modules and carries it to a heat exchanger or radiator. This cold plate liquid cooling system ensures efficient heat removal and stable operating temperatures.

High thermal performance: Seamless metal bonds reduce thermal resistance.

Leak-free and durable: Vacuum brazing ensures strong joints that resist leaks and corrosion.

Customizable: Custom liquid cold plates can be designed for specific channel layouts, sizes, and applications.

Compact design: Ideal for high-density electronics, EV battery modules, and aerospace applications.

Most liquid cooling plates are made from high-purity copper or aluminum, or a combination of both for hybrid designs. Copper offers superior thermal conductivity, while aluminum provides lightweight advantages. The choice depends on application requirements, including thermal load, weight, and cost considerations.

Yes. We offer custom liquid cold plate solutions tailored to your needs, including:

Specific channel geometries for optimal coolant flow

Multi-inlet/outlet designs

Different material selections (copper, aluminum, or hybrid)

Surface treatments for corrosion resistance or enhanced heat transfer

Our brazed liquid cold plates are widely used in:

High-power electronics and semiconductor cooling

Data centers and server racks

Electric vehicle battery thermal management

Aerospace and defense electronics

Industrial laser and robotic systems

Yes. The vacuum brazing process ensures seamless, metallurgically bonded joints, making brazed liquid cold plates highly resistant to leaks, even under high pressure or thermal cycling conditions.

Consider the following factors when selecting a high-performance cold plate:

Thermal load and heat flux requirements

Coolant type and flow rate

Space constraints and mounting options

Material preference (copper for maximum conductivity, aluminum for lightweight design)

Customization requirements for complex systems

Yes. As a professional Vacuum Brazing Liquid Cold Plate manufacturer and supplier, we can handle both small custom orders and large-scale production, providing consistent quality and reliable delivery schedules.

Maintenance is straightforward:

Regularly inspect for leaks and corrosion

Ensure coolant is clean and compatible with the plate material

Flush the system periodically to remove debris or buildup

Monitor operating temperatures to maintain performance

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018