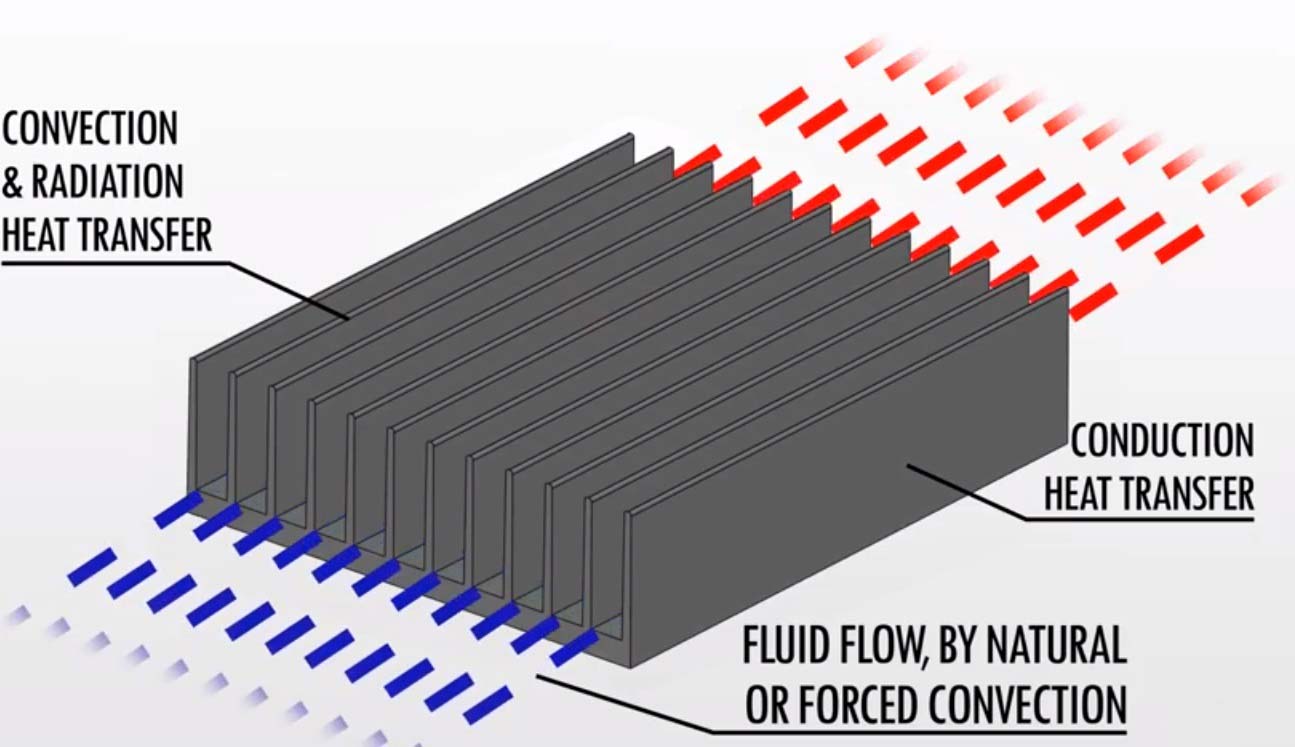

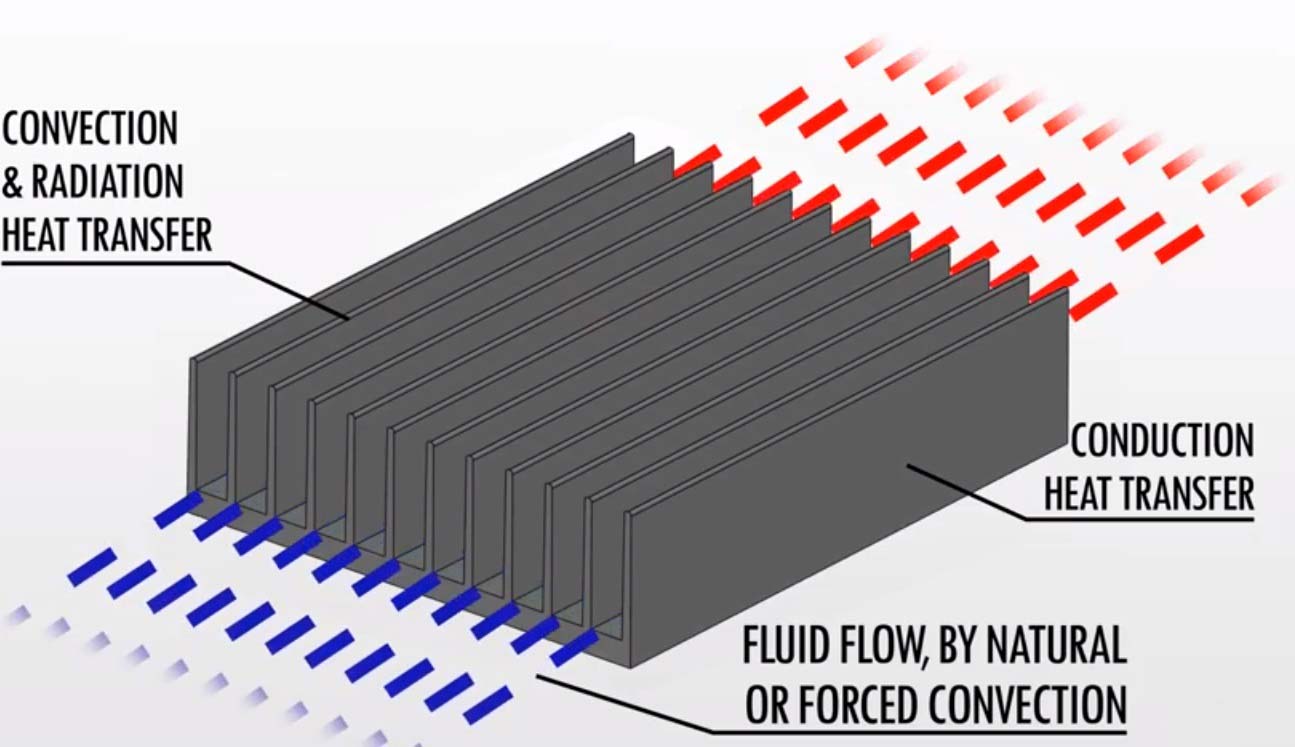

extruded aluminum heatsinks are made by heating and extruding aluminum with thermal conductivity into custom shapes with fins, ribs, or other designs. These heatsinks are widely used as efficient thermal management components in electronic devices, industrial equipment, automotive sectors, and new energy industries. They primarily help dissipate heat from electronics, machinery, and other heat-generating components, preventing overheating and ensuring stable operation.

Main Applications:

Heat Dissipation: extruded aluminum heatsinks accelerate the transfer of heat from components to the surrounding air, preventing overheating.

Optimal Operation: They help maintain devices within the ideal temperature range, extending the lifespan and improving performance.

Component Protection: Sensitive electronic components can be damaged by high temperatures, but Extruded Aluminum Heatsinks prevent this, ensuring the safety of the equipment.

Energy Efficiency: By reducing the load on cooling systems, Extruded Aluminum Heatsinks contribute to lower energy consumption.

Temperature Stability: In applications such as industrial, automotive, or consumer electronics, the temperature stability provided by aluminum extruded thermal sinks is critical for long-term operation and effective temperature control.

Aluminum Material Properties:

Aluminum used for Extruded Aluminum Heatsinks has high thermal conductivity (approximately 205 W/m·K), which allows efficient heat transfer from heat-generating components like CPUs, LEDs, and power electronics to the surrounding environment. This ensures even heat distribution across the heatsink, minimizing hotspots and maintaining stable temperatures for critical devices. Compared to other metals like copper, aluminum strikes a balance between excellent heat transfer and a lightweight structure, making it ideal for applications requiring both weight and thermal management, such as automotive, consumer electronics, and telecom equipment.

High Thermal Efficiency of heat sink Extrusions:

Heat sink extrusions feature complex fin designs that increase surface area, maximizing heat dissipation to the surrounding air and promoting better airflow, especially in active or passive air circulation systems. Made from high thermal conductivity aluminum (205 W/m·K), they quickly absorb and evenly distribute heat, preventing hotspots and enhancing overall cooling efficiency. Additionally, their lightweight nature and customizable designs make them ideal for high-performance applications with weight constraints. Kingka Heat Sink Extrusions offer custom designs based on drawings and are suitable for large-scale production.

Applications of Aluminium Heat Sink Extrusion:

Electronics: Used in CPUs, graphics cards, power supplies, and LED lighting to dissipate heat quickly, preventing overheating and extending component life.

Electric Vehicles and Automotive Electronics: Essential for battery management systems, inverters, and other key components, helping improve vehicle performance and range.

Industrial Automation: Equipment such as servo motors and inverters rely on aluminum heatsinks to maintain efficient, long-term operation and avoid heat-related failures.

Telecom Equipment: Aluminum heat sinks are used in base stations and servers, ensuring low temperatures in high-power environments and reducing failure rates.

LED Lighting: Streetlights and other LED systems depend on aluminum heatsinks to control temperatures, extend the lifespan of lights, and improve energy efficiency.

Household Appliances: Aluminum heatsinks are used in refrigerators, air conditioners, and televisions to improve efficiency, extend the life of the devices, and reduce energy consumption.

Kingka, an extruded aluminum heatsink manufacturer, offers custom designs to meet client specifications, tailoring fin shapes, sizes, and spacing to maximize heat dissipation based on specific thermal requirements. Common aluminum alloys such as 6063, 6061, 1050, 6060, and 6082 are available, ensuring the chosen alloy meets the conductivity, strength, and corrosion resistance demands of the application. Additional surface treatments, such as anodizing or powder coating, are available to enhance the thermal performance and durability of the heatsinks.

Feel free to contact us and visit our website to learn more about custom heat sink solutions!