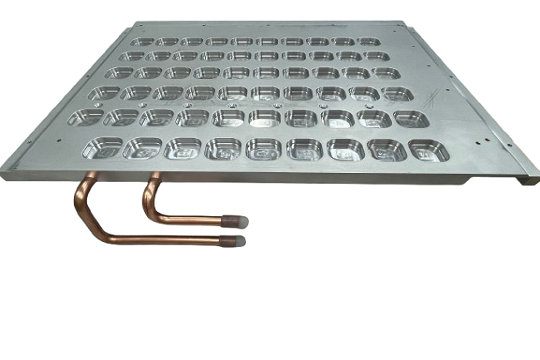

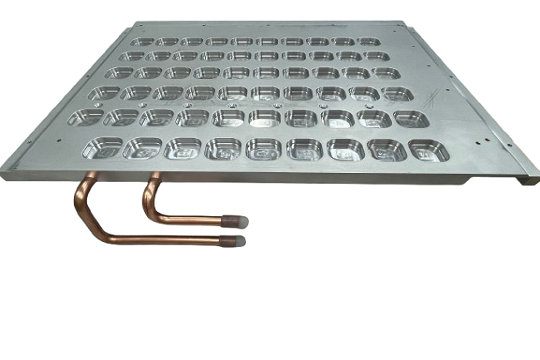

Extruded liquid cold plates are integrated thermal management components manufactured through aluminum alloy extrusion processes. These liquid cold plates utilize liquid cooling media—such as water, water–glycol mixtures, or fluorinated fluids—to achieve efficient heat exchange.

The core feature of this cold plate liquid cooling technology is the formation of enclosed or multi-cavity internal flow channels within a single extruded aluminum profile. This structure provides low flow resistance, high pressure tolerance, compact design, and controlled cost, making it widely used in high power density electronics, battery packs, server liquid cooling, and power electronics.

Understanding how liquid cold plates work is critical: heat is conducted from the heat source into the cold plate body, transferred to the internal liquid flow channels, and then carried away by forced convection. Compared with tubed cold plates or brazed liquid cold plates, extruded designs offer higher structural integrity and reduced leakage risk.

Core Technical Characteristics

One-piece extruded flow channels

Seamless internal channels formed during extrusion eliminate weld seams and reduce leakage risk compared to brazed or tubed structures.

High thermal conductivity materials

Typically manufactured from 6061 or 6063 aluminum alloys with thermal conductivity ≥ 180 W/m·K. While copper cold plates offer higher conductivity, aluminum provides a superior balance of weight, cost, and corrosion resistance.

Customizable flow channel designs

Supports parallel channels, serpentine channels, and multi-cavity configurations, enabling flexible Liquid Cold Plate design.

High pressure capability

Typical operating pressure: 0.5–1.5 MPa

Burst pressure: ≥ 3.0 MPa

Lightweight structure

20–40% lighter than CNC-machined or plate liquid cooling solutions.

Excellent surface treatment compatibility

Suitable for anodizing, electroless nickel plating, and functional coatings.

Typical Application Scenarios

Electric vehicle battery pack water cooling plate systems

Server CPU / GPU cold plates for electronics

High-power laser cooling systems

IGBT and power module cold plate cooling

Energy storage system thermal management

Extruded Liquid Cold Plates Manufacturing Process

1. Raw Material Preparation Stage

Aluminum billet selection → Chemical composition analysis (spectrometer) → Mechanical property testing (hardness, tensile strength) → Pre-processing (cutting, end-face machining) → Material warehousing

2. Die Design and Manufacturing Stage

Flow channel design (CFD thermal simulation optimization) → Extrusion die design (port holes, welding chamber, bearing land) → Die steel selection (H13 hot work tool steel) → CNC rough machining → Heat treatment (quenching + triple tempering) → Precision machining (EDM, wire cutting) → Polishing (bearing land Ra ≤ 0.4 μm) → Trial extrusion validation

This stage directly determines the internal geometry and performance of extruded liquid cold plates, distinguishing them from brazed liquid cold plate structures that rely on post-assembly bonding.

3. Extrusion Forming Stage

Aluminum billet preheating (480–520°C) → Die preheating (450–480°C) → Extrusion parameter setup → Profile extrusion (speed 1–5 m/min) → Online quenching (air or mist cooling) → Pulling and straightening → Fixed-length cutting → Aging treatment (T5 / T6 condition)

The extrusion process enables consistent internal flow channels that support stable plate liquid cooling performance.

4. CNC Precision Machining Stage

Datum surface machining (coordinate system establishment) → End-face machining (flow channel opening) → Interface machining (inlet/outlet ports, mounting holes) → Sealing surface machining (flatness ≤ 0.05 mm) → Deburring → Cleanliness inspection

Machining Requirements

5. End Cap Machining and Welding Preparation

End cap material selection (same or compatible alloy) → CNC finishing → Sealing surface finishing (Ra ≤ 1.6 μm) → Welding groove machining → Cleaning (ultrasonic cleaning) → Assembly positioning (dedicated fixtures)

End Cap Design Parameters

6. Welding and Sealing Stage

Welding process selection → Fixture assembly → Welding parameter setup → Automated welding execution → Post-weld heat treatment (stress relief) → Weld appearance inspection

Welding Process Comparison

Friction Stir Welding (FSW):

No filler material, high joint strength, ideal for long straight seams

Laser Welding:

Small heat-affected zone, high precision, suitable for complex seams

TIG Welding:

Cost-effective, flexible, suitable for small-batch custom liquid cold plate production

7. Pressure and Sealing Tests

Helium leak testing

Hydrostatic pressure testing (1.5× working pressure)

Burst pressure testing (≥ 3× working pressure)

Pressure cycle testing (100,000 cycles)

Test Standards

Leak rate: ≤ 1×10⁻⁷ mbar·L/s (helium)

Pressure holding: 1.5 MPa × 5 min, pressure drop ≤ 0.01 MPa

Burst pressure: ≥ 3.0 MPa

Pressure cycling: 0.2–1.0 MPa, 100,000 cycles without leakage

8. Surface Treatment Stage (Optional)

Pre-treatment (degreasing, pickling) → Anodizing (natural / black) → Sealing → Functional coatings → Baking and curing

Surface Treatment Options

Anodizing:

Electroless nickel plating:

PTFE coating:

Improved chemical resistance

Insulating coatings:

For electrical isolation requirements

9. Cleaning and Drying Process

High-pressure DI water flushing → Ultrasonic cleaning (neutral detergent) → Triple-stage counterflow rinsing → Hot air drying (80–100°C) → Vacuum drying (high-reliability applications) → Nitrogen filling for oxidation prevention

Cleanliness Standards

10. Accessory Assembly

Seal installation (silicone / FKM / EPDM) → Quick-connect fittings assembly → Temperature sensor installation (optional) → Pressure sensor installation (optional) → Labeling (product info and flow direction)

Accessory Requirements

Seal materials: EPDM, FKM, silicone (−40°C to 150°C)

Connector standards: DIN, SAE, JIS, BSPP

Sensor accuracy:

Temperature ±0.5°C

Pressure ±1% FS

11. Finished Product Performance Testing

Thermal resistance testing (standard heat source method) → Flow resistance testing (flow vs. pressure drop curve) → Flow uniformity testing (multi-channel designs) → Durability testing (thermal and pressure cycling) → Final helium leak reinspection (100% inspection)

Performance Indicators

Thermal resistance: 0.01–0.05 °C/W (design and flow dependent)

Flow resistance: ≤ 50 kPa @ 10 L/min (typical)

Flow uniformity deviation: ≤ 10%

Operating temperature range: −40°C to 120°C

12. Final Inspection and Packaging

Visual inspection → Dimensional sampling (CMM) → Documentation preparation → Anti-corrosion packaging (VCI) → Shockproof packaging → Outer carton labeling

Packaging Specifications

Single-unit protection: PE bag + VCI paper

Packing orientation: Vertical placement

Label content: Product ID, production date, flow direction, fragile marking

Storage conditions: −10°C to 40°C, ≤ 70% RH

13. Documentation and Traceability

Certificate of conformity → Material certificates → Performance test reports → Process records → Traceability labels (QR code / barcode) → Installation and operation manual

Critical-to-Quality (CTQ) Control Points

| Process Stage | Control Parameter | Method | Acceptance Criteria |

|---|

| Raw Material | Chemical composition | Spectral analysis | Conforms to 6061/6063 |

| Extrusion | Channel dimensions | Caliper / projector | ±0.1 mm |

| Machining | Flatness | Granite plate | ≤0.05 mm / 100 mm |

| Welding | Leak integrity | Helium leak test | ≤1×10⁻⁷ mbar·L/s |

| Surface | Coating thickness | Eddy current gauge | 10–15 μm ±2 μm |

| Final Test | Pressure resistance | Burst test | ≥3.0 MPa |

Process Capability and Production Capacity

Design Guidelines and Best Practices

Flow Channel Design

Hydraulic diameter: 4–8 mm

Aspect ratio: ≤ 10:1

Bend radius: ≥ 1.5× channel width

Bell-mouth inlet/outlet design

Optional internal fins for enhanced heat transfer

Structural Design

Uniform wall thickness

Reinforcement ribs at critical locations

Stress-free mounting layout

Thermal expansion allowance

Material Selection Strategy

General applications: 6063-T5

High-performance applications: 6061-T6

Harsh environments: Additional coatings

Cost Optimization

Standardized cross-sections

Improved material utilization

Reduced secondary machining

Economies of scale in mass production

With their one-piece extruded structure, low leakage risk, high reliability, and excellent cost efficiency, extruded liquid cold plates play an irreplaceable role in high power density cold plate cooling applications. As industries such as electric vehicles, data centers, 5G communications, and renewable energy continue to grow, Custom Cold Plates and custom liquid cold plate solutions will evolve toward higher performance, lighter weight, and smarter thermal management—providing robust and scalable solutions for next-generation liquid cooling systems.