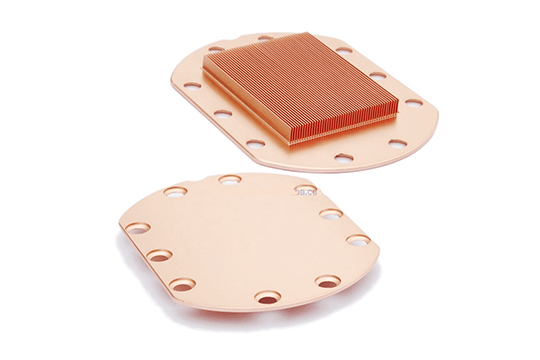

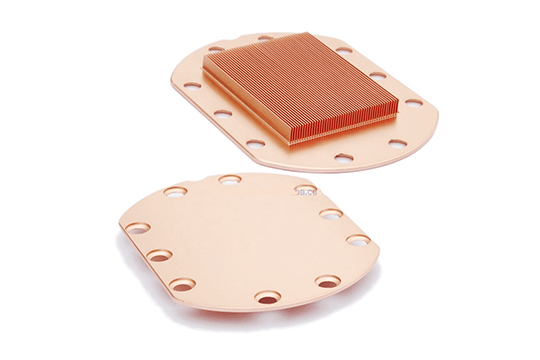

A heat sink is a thermal management component designed to dissipate heat from electronic devices into the surrounding environment. In Heat Sinks for electronics, heat is transferred through conduction from the heat source (such as a CPU or power module) into the heat sink base, then dispersed via heat sink fins through convection and radiation.

Understanding what is a heat sink, how heat sinks work, and how heat sinks are made is essential when selecting solutions such as aluminum heat sinks, copper heat sinks, liquid cooled heat sinks, or custom heatsinks for industrial and electronic applications.

Among all manufacturing methods, CNC machined heat sinks offer the highest design freedom and precision, making them ideal for complex, high-performance, and low-volume applications where extruded heat sinks or heat sink extrusion cannot meet design requirements.

1. Raw Material Management Stage

1.1 Metal Billet Preparation

Material Selection

High thermal conductivity metals and composites are selected according to thermal and mechanical requirements:

Aluminum alloys: AA6061-T6 / AA6063-T5 / T651

Copper alloys: C1100 / C1020

Composite materials: AlSiC, CuW

These materials are commonly used in aluminum heatsinks, copper heat sinks, and high-end industrial heat sink solutions.

Material Certification & Verification

Physical Property Testing

Thermal conductivity:

Aluminum ≥ 180 W/m·K

Copper ≥ 380 W/m·K

Hardness:

6061-T6: HB 95–100

6063-T5: HB 75–85

Tensile strength:

6061-T6 ≥ 290 MPa

6063-T5 ≥ 175 MPa

Billet Pre-Treatment

Stress relief (if required): 300°C × 2 hours, furnace cooling

Surface flatness check: ≤ 0.1 mm / 100 mm

Dimensional tolerance: ±0.5 mm (L × W × H)

1.2 Auxiliary Materials Preparation

Cutting tools:

Coolant systems:

Fixture materials:

2. Process Design and CAM Programming Stage

2.1 Machining Strategy Development

Process Route Planning

Rough machining: High-speed milling (80–90% material removal)

Semi-finishing: Contour machining with 0.1–0.2 mm allowance

Finishing: Precision machining to final dimensions

Toolpath Optimization

Contour machining: Step-over 0.5–2.0 mm

Parallel toolpaths: 30–70% tool diameter

Spiral toolpaths: Reduced tool entry impact

Deformation Control Strategies

2.2 CAM Programming

3D Model Processing

Model repair and simplification

Machining allowance setup:

Roughing: 0.3–0.5 mm

Finishing: 0–0.05 mm

Feature-based machining region segmentation

Toolpath Generation

Post-Processing & Simulation

NC code generation for specific CNC systems

Collision and travel verification

Machining time estimation (±10%)

3. Machining Preparation Stage

3.1 CNC Machine Setup

Machine Selection

3-axis vertical machining centers: Standard CNC machined heat sinks

4-axis / 5-axis CNC: Complex curved surfaces

High-speed machining centers: Spindle ≥ 12,000 rpm for thin fins

Machine Accuracy Verification

3.2 Fixture System Design

Clamping Force Control

Hydraulic clamping: 0.5–1.0 MPa

Pneumatic clamping: 0.4–0.6 MPa

Mechanical clamping: Torque controlled to ±0.1 Nm

4.1 Rough Machining

Workpiece alignment using edge finders (±0.01 mm)

Coordinate systems: G54–G59

Primary datum surface machining (flatness ≤ 0.02 mm)

Rough Cutting Parameters

Spindle speed: 8000–12,000 rpm

Feed rate: 1500–3000 mm/min

Depth of cut: 2–5 mm

Step-over: 60–70% tool diameter

Process Monitoring

4.2 Semi-Finishing

In-Process Control

4.3 Finishing (Critical Process)

Heat Sink Fin Machining

Thin fin processing using φ1–φ3 mm end mills

Spindle speed: 18,000–24,000 rpm

Feed rate: 300–800 mm/min

High-pressure internal coolant (≥70 bar)

Anti-Vibration Measures

Mounting Surface Machining

Face milling (φ40–φ80 mm cutters)

Surface roughness: Ra ≤ 0.8 μm

Flatness: ≤ 0.03 mm / 100 mm

Hole Machining

Special Structures

T-slots and profiled grooves

5-axis curved surface machining

Micro-structure machining (φ0.1–φ0.5 mm tools)

4.4 Advanced Machining Technologies

5. In-Process Quality Control

5.1 Online Inspection

Touch probes for alignment and dimensional inspection

Automatic tool compensation

Laser scanning for surface profiles

Vision systems for defect detection

5.2 Process Parameter Monitoring

6. Critical-to-Quality (CTQ) Control Points

| Stage | Parameter | Method | Standard |

|---|

| Raw Material | Thermal Conductivity | Laser Tester | ≥180 W/m·K |

| Machining | Spindle Runout | Dial Indicator | ≤0.003 mm |

| Dimensional | Mounting Flatness | Granite Plate | ≤0.03 mm/100 mm |

| Surface | Roughness | Roughness Tester | Ra ≤0.8 μm |

| Thermal | Thermal Resistance | Test Bench | ≤ Design +10% |

| Reliability | Salt Spray | Test Chamber | ≥96 hours |

7. Process Capability and Lead Time

Total Lead Time: 18–31 working days

Capacity:

8. Process Characteristics and Advantages

Technical Advantages

Extremely high design freedom

Micron-level precision

Suitable for custom heatsink solutions

Ideal for CPU heatsink, CPU heatsink fan, heatsink fan, heat sink with fan, and liquid cooled heat sink designs

Process Limitations

Recommended Applications

Prototypes and validation

Small-batch, high-value products

Complex geometry heat sinks

High-performance industrial heat sinks

Not recommended for:

High-volume standardized products

Cost-sensitive applications

Simple extruded heat sink designs

This CNC machined heat sink manufacturing process is optimized for high-precision, complex, and low-volume heat sink production. By combining optimized machining strategies, strict process control, and advanced inspection methods, heat sink manufacturers can achieve superior thermal performance, dimensional accuracy, and long-term reliability. The process can be flexibly adjusted to balance performance and cost according to specific application requirements.