As modern electronics continue to advance, the demand for high-performance devices with fast processors and high transistor density is growing rapidly. While these devices offer incredible computational power, they also generate significant heat during operation. Without proper thermal management, this heat can lead to component failure, reduced performance, and shortened device lifespan. This is where a heat sink comes into play—a critical component designed to dissipate heat efficiently and ensure stable operation.

In this guide, we will explore what a heat sink is, how does a heat sink work, what does a heat sink do, what is the purpose of a heat sink, and how to design a heat sink. Additionally, we will cover common materials, designs, and applications for both standard and custom cooling solutions, such as custom heatsink, aluminum heat sink, CPU heatsink, heat sink extrusion, and heat pipe heatsink.

What Is a Heat Sink?

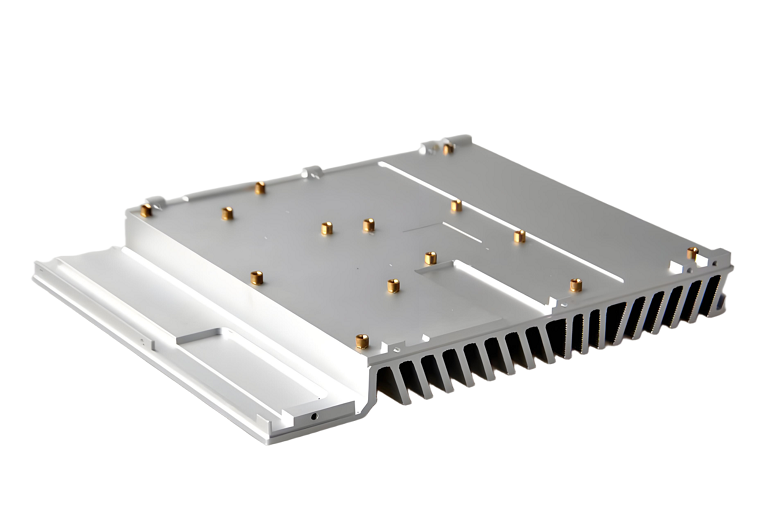

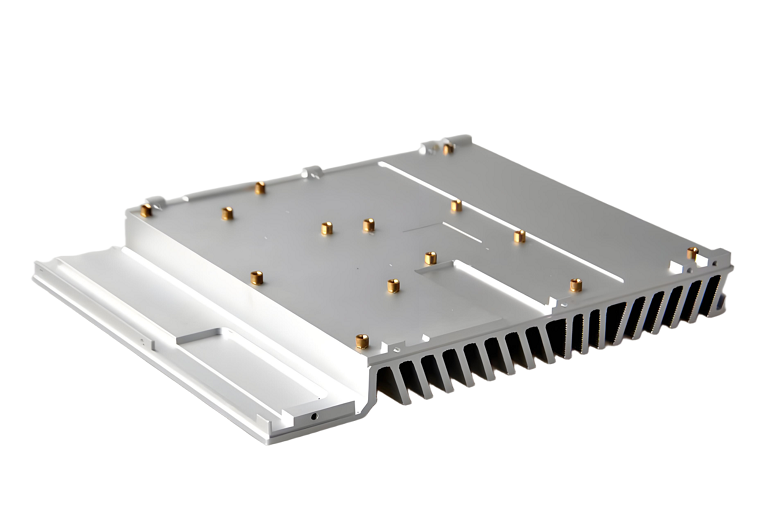

A heat sink is a mechanical component used in electronic devices to transfer heat away from sensitive components to the surrounding environment. Its main function is to prevent electronic parts, such as CPUs, power transistors, diodes, voltage regulators, and integrated circuits, from overheating.

Types of heat sinks include:

Extrusion Heat Sink: Made by extruding aluminum or copper to form fins, ideal for standard applications.

Skived Fin Heat Sink: Fins are sliced and bent from a solid block, providing high surface area for efficient heat transfer.

Bonded Fin Heat Sink: Separate fins are attached to a base through soldering or adhesive bonding.

Cold forging heat sink: High-density fins are created through forging, offering excellent thermal performance.

Die-casted heat sink: Suitable for complex shapes and mass production.

Heat pipe thermal module: Uses heat pipes to rapidly transfer heat from high-power components to the fins for efficient cooling.

For specialized applications, custom heatsink solutions are often designed to fit unique electronic layouts, ensuring optimal cooling performance.

How Does a Heat Sink Work?

A heat sink works by absorbing heat from electronic components and dissipating it into the surrounding medium, usually air or a liquid coolant. The heat transfer occurs through three primary mechanisms:

Conduction: Heat travels from the component to the heat sink base.

Convection: Heat moves from the heat sink fins to the air or liquid flowing around it.

Radiation: Some heat is emitted as infrared radiation.

For enhanced performance, many heat sinks incorporate heat pipe technology. A heat pipe heatsink can transfer heat quickly from a concentrated source to a larger fin array, improving thermal efficiency, especially in high-power CPUs or GPU modules.

What Does a Heat Sink Do?

The primary function of a heat sink is to prevent overheating and maintain a stable operating temperature for electronic devices. Key benefits include:

Thermal regulation: Heat sinks maintain controlled temperatures within the device, preventing thermal spikes.

Enhanced reliability: By reducing heat stress, heat sinks improve the lifespan and stability of electronic components.

Performance consistency: Components operate efficiently under optimal temperature, ensuring consistent device performance.

Versatility: Heat sinks are widely used across consumer electronics, industrial devices, LED lighting, and server hardware.

A well-designed CPU heatsink ensures that processors can handle high workloads without throttling, while aluminum heat sinks in power modules or LED drivers provide lightweight, cost-effective cooling.

What Is the Purpose of a Heat Sink?

The purpose of a heat sink extends beyond simple cooling: it ensures the overall thermal management of electronic systems. Heat sinks prevent the internal components of electronics from reaching unsafe temperatures, which could lead to permanent damage or reduced efficiency.

In high-performance applications, such as gaming PCs, servers, and industrial electronics, a custom heatsink may be designed to meet precise thermal requirements, ensuring that even high-density components remain safe and reliable.

How to Design a Heat Sink

Designing a heat sink involves understanding the heat dissipation requirements and optimizing the device for efficiency. Critical factors in how to design a heat sink include:

1. Thermal Resistance (Rth)

Thermal resistance measures how easily heat flows from the component to the environment. The lower the thermal resistance, the more efficiently heat is dissipated.

Rhs=PTj−TAMB−Rth−jc−Rinterface

Where:

Tj = junction temperature

TAMB = ambient temperature

P = power dissipation

Rth−jc = junction-to-case thermal resistance

Rinterface = thermal interface material resistance

2. Material Selection

Most heat sinks are made of aluminum or copper:

Aluminum heat sink: Lightweight, low-cost, easy to extrude, widely used in electronics.

Copper heat sink: High thermal conductivity, ideal for high-power applications.

Custom heatsink solutions may combine materials to balance cost, weight, and thermal efficiency.

3. Thermal Interface Material (TIM)

TIM is placed between the component and the heat sink base to reduce contact resistance and enhance heat transfer. Common TIMs include thermal grease, phase-change materials, or mica pads.

4. Fin Design

The shape, thickness, and arrangement of fins are crucial. Efficient heat sink extrusion designs or skived fins increase surface area, facilitating faster heat transfer through air or liquid flow.

5. Mounting Methods

Proper attachment of the heat sink to components ensures minimal thermal resistance:

Thermal adhesive or tape

Clips or brackets

Spring-loaded screws

What Are Heat Sinks Made Of?

Heat sinks can be manufactured from a variety of materials depending on application needs:

Aluminum: Lightweight, cost-effective, easily shaped via extrusion or die casting.

Copper: High thermal conductivity, ideal for high-power heat dissipation.

Composite materials: Offer specialized performance for demanding applications.

Common manufacturing techniques include extrusion heat sink, skived fin heat sink, bonded fin heat sink, cold forging heat sink, and die-casted heat sink. For high-performance electronics, heat pipe thermal module solutions combine heat pipes with fins for superior cooling.

Heat Sink Applications

Heat sinks are essential in almost all electronics:

CPU heatsink: Ensures processors operate under heavy loads without thermal throttling.

Aluminum heat sink: Used in LED drivers, power modules, and telecommunications equipment.

Heat pipe heatsink: Transfers high heat flux efficiently in GPUs, servers, and industrial electronics.

Custom heatsink: Tailored solutions for unique electronic layouts, maximizing performance and space efficiency.

Flexible heat sink: Designed for applications with irregular surfaces or limited space.

By choosing the appropriate type, material, and design, heat sinks can meet even the most demanding thermal management requirements.

A heat sink is an essential component in electronic devices that absorbs and dissipates heat to prevent overheating. Understanding what is a heat sink, how does a heat sink work, what does a heat sink do, and what is the purpose of a heat sink is critical for engineers and designers.

From standard aluminum heat sinks to high-efficiency heat pipe heatsinks and tailored custom heatsink solutions, effective thermal management ensures electronic devices operate reliably and efficiently. Incorporating proper materials, fin design, thermal interfaces, and mounting methods allows engineers to optimize heat sink extrusion, CPU heatsink, and other cooling solutions for both performance and longevity.