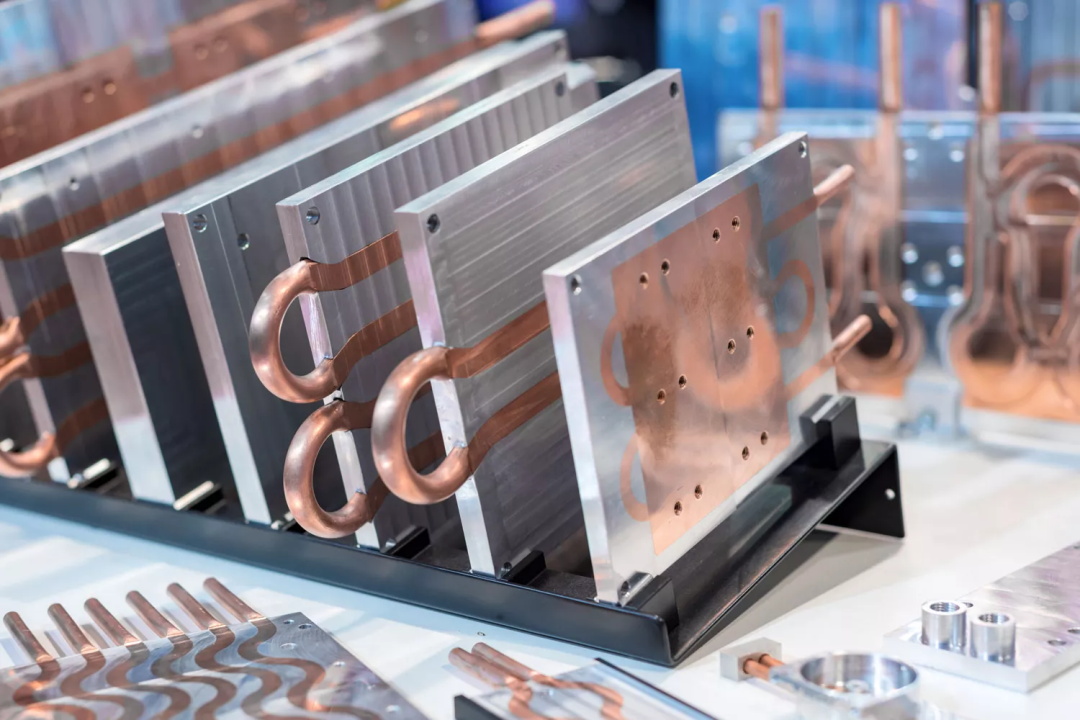

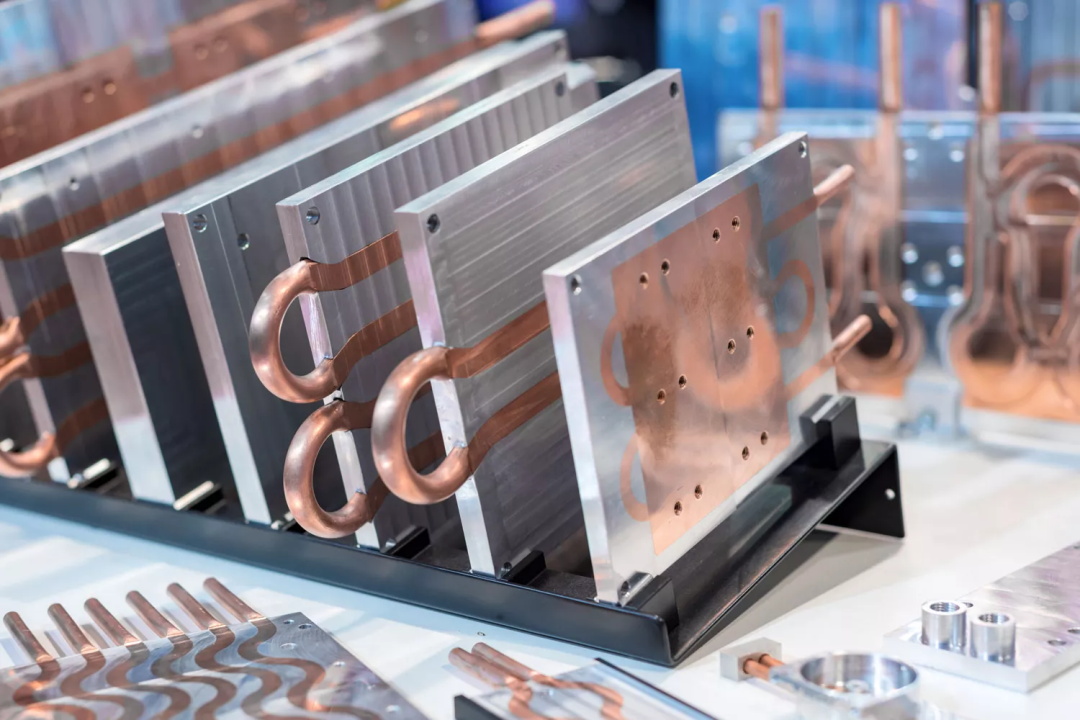

With the rapid growth of data centers, AI servers, and high-performance computing (HPC) platforms, liquid cooling cold plates have become a critical component of modern thermal management systems. In particular, water cooling plates and liquid cold plates are widely adopted for removing high heat flux from CPUs, GPUs, and AI accelerators.

However, conventional water cold plate cooling solutions face several inherent challenges during long-term operation. KINGKA addresses these challenges through advanced engineering, precision manufacturing, and proven Liquid Cold Plate solutions for data centers.

1. Corrosion Issues in Conventional Water Cooling Plates

Problem: Corrosion in Brazed Water Cold Plates

Most traditional water cooling cold plates use brazed copper microchannel structures. The combination of copper substrates and brazing filler metals introduces electrochemical potential differences, which can cause galvanic corrosion when exposed to water-based coolant.

Additional corrosion mechanisms include:

Over time, corrosion degrades internal microchannels, reducing the reliability of cold plate cooling systems.

KINGKA Solution: Corrosion-Resistant Liquid Cold Plate Design

KINGKA reduces corrosion risks through:

High-purity copper and aluminum materials for liquid cold plate manufacturing

Friction Stir Welding (FSW) cold plate technology, eliminating brazing materials

Smooth, precision-machined microchannels to reduce corrosion initiation

Strict material certification and environmental compliance (RoHS / REACH)

By adopting FSW water cooling cold plates, KINGKA significantly improves chemical stability and service life.

2. Blockage Risks in Microchannel Liquid Cold Plates

Problem: Flow Restriction in Water Cooling Plates

Microchannel liquid cooling plates are highly sensitive to contamination. Scale deposits, oxidation particles, and biological growth can accumulate inside channels, causing partial or complete blockage.

This leads to:

KINGKA Solution: Optimized Microchannel Cold Plate Engineering

KINGKA minimizes blockage risks by:

High-precision CNC Machining for consistent microchannel geometry

Controlled surface roughness in water cold plate fabrication

Multi-stage ultrasonic cleaning before and after welding

Flow resistance testing for every liquid cold plate for data center applications

This ensures long-term flow stability and reliable liquid cooling cold plate performance.

3. Leakage Risks in Water-Based Cold Plate Cooling Systems

Problem: Coolant Leakage and Electrical Safety

Conventional water cooling plate systems rely on seals, hoses, and multiple connection points. Thermal cycling and pressure fluctuations accelerate aging of O-rings and tubing, increasing leakage risk.

Because water is electrically conductive, even minor leakage can cause:

This is a major concern for AI data center liquid cooling systems.

KINGKA improves system safety through:

FSW liquid cold plate welding, creating dense, pore-free joints

Gas/Liquid Leakage Test and Pressure Holding Test for every cold plate

Structural optimization to reduce stress at joints

Assembly-ready water cooling plates with verified sealing integrity

These measures make KINGKA’s liquid cold plate cooling solutions suitable for continuous high-load operation.

4. Thermal Performance Stability for High-Power AI Chips

Problem: Uneven Cooling and Thermal Hot Spots

As AI accelerators exceed kilowatt-level power density, inconsistent coolant distribution can lead to uneven temperature profiles, reducing performance and component lifespan.

KINGKA Solution: High-Performance Cold Plate Cooling Design

KINGKA ensures stable thermal performance through:

CFD-based thermal simulation during cold plate design

Uniform flow distribution in liquid cold plate cooling systems

Precision flatness control for optimal thermal contact

Thermal resistance validation under real operating conditions

This enables reliable cold plate cooling for AI servers and data centers.

5. Why KINGKA Liquid Cold Plates for Data Centers

KINGKA provides complete liquid cooling cold plate solutions, combining:

15+ years of experience in thermal management

Advanced friction stir welding cold plate manufacturing

Precision CNC machining and strict quality control

Custom water cooling plate design for AI, HPC, and data center applications

From prototype to mass production, KINGKA delivers reliable liquid cold plate solutions optimized for performance, safety, and long-term operation.

While traditional water cold plates face challenges such as corrosion, blockage, and leakage, these risks can be effectively mitigated through advanced design and manufacturing. KINGKA’s FSW liquid cold plates, precision machining, and rigorous testing provide a robust and scalable solution for next-generation data center liquid cooling systems.