1. AI Computing Power Is Redefining Data Center Infrastructure

In the era of the digital economy, computing power has become the core productivity, following thermal energy and electricity. With the rapid development of artificial intelligence, cloud computing, and high-performance computing (HPC), data centers are evolving into the backbone of industries such as transportation,finance,manufacturing, healthcare, telecommunications, energy, and scientific research.

According to IDC and CAICT forecasts, global AI computing power is expected to exceed 16 ZFLOPS by 2030, with AI-driven intelligent computing accounting for over 90% of total computing demand. From 2023 to 2030, the global AI market is projected to grow at a compound annual growth rate exceeding 35%, with market size surpassing USD 11 trillion.

As AI becomes the core market driving force, the rapid increase in chip power density is fundamentally reshaping data center thermal management requirements.

2. Rising AI Chip Power Density Creates Severe Thermal Challenges

Modern AI chips—including GPUs, ASICs, and high-end accelerators—are pushing thermal design power (TDP) to unprecedented levels:

High-end GPUs for AI training now exceed 700–1400 W, with next-generation products approaching 2000 W and above

ASIC accelerators and FPGA platforms continue to increase power density to maximize performance per rack

High-density server deployments significantly reduce available airflow and heat dissipation margins

Under such conditions, traditional air-cooling architectures face clear limitations.

According to the “10-degree rule” in electronics reliability, every 10°C increase in operating temperature reduces component lifespan by 30–50%. Overheating not only threatens system stability but also increases failure rates and maintenance costs.

3. Why Liquid Cooling Is Becoming Essential for Data Centers

3.1 Energy Efficiency and PUE Optimization

Power Usage Effectiveness (PUE) has become a critical metric for modern data centers:

Traditional air-cooled data centers typically operate at PUE 1.4–1.5

Liquid-cooled data centers can achieve PUE below 1.2, and in some architectures even lower

Liquid cooling significantly reduces fan power consumption and improves overall energy utilization, directly lowering operating costs and carbon footprint.

3.2 Support for High-Density Deployment

As rack power density continues to rise, airflow-based cooling struggles to scale. Liquid cooling enables:

Higher heat flux handling per unit area

More compact server layouts

Flexible deployment in constrained spaces

3.3 Improved Reliability and Thermal Control

Liquid cooling allows direct heat extraction from the chip, reducing thermal resistance and ensuring stable junction temperatures under sustained high loads.

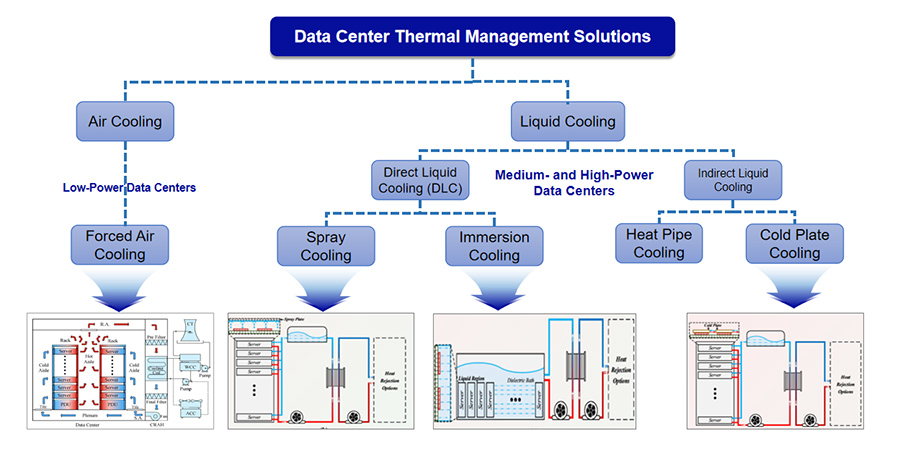

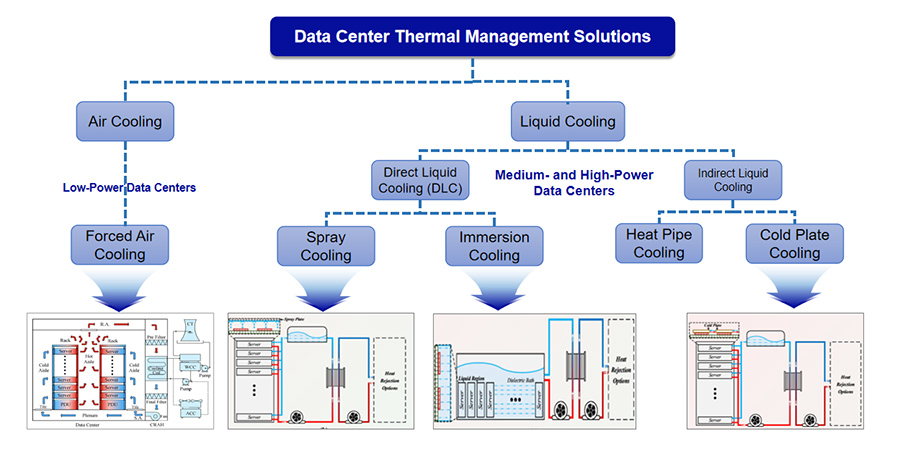

4. Overview of Data Center Liquid Cooling Technologies

4.1 Liquid Cooling System Types

Technology | Cooling Efficiency | PUE Range | Maturity | Key Characteristics |

Single-phase Cold Plate | Medium–High | 1.10–1.20 | High | Most widely adopted |

Two-phase Cold Plate | High | 1.05–1.15 | Low | High efficiency, complex control |

Single-phase Immersion | High | 1.05–1.10 | Medium | High system integration |

Two-phase Immersion | Highest | 1.03–1.05 | Low | Extreme performance, high cost |

Spray Cooling | High | 1.05–1.10 | Low | Niche applications |

Among these solutions, cold plate liquid cooling remains the most mature and widely deployed approach in AI data centers due to its balance of efficiency, maintainability, and compatibility with existing server architectures.

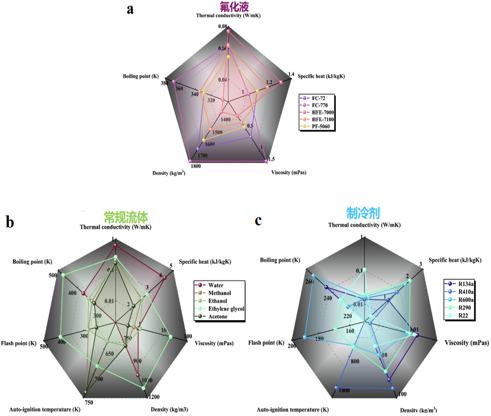

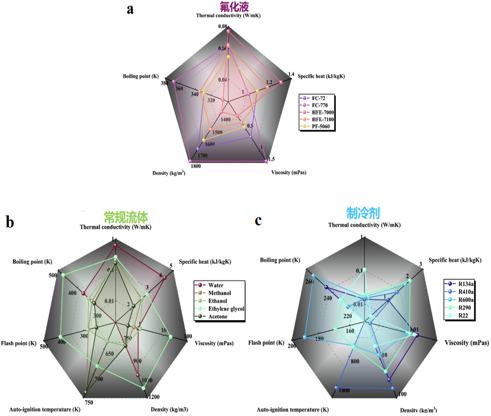

5. Cooling Fluids and Thermal Performance Considerations

Cooling fluid properties directly influence system safety, efficiency, and sustainability. Compared with water-based systems, dielectric refrigerants used in two-phase cooling offer distinct advantages, including electrical insulation and phase-change heat transfer.

Key performance indicators include boiling point, latent heat, operating pressure, thermal conductivity, and environmental impact (GWP).

Two-phase refrigerants enable high heat transfer at lower flow rates, reducing pump power and improving overall system efficiency.

6. Challenges of Conventional Water Cold Plates

While water-based cold plates are widely used, they present several inherent risks in long-term operation:

6.1 Corrosion Risks

Copper microchannel cold plates assembled by brazing may experience galvanic corrosion due to material potential differences, compounded by oxygen, acidity, and microbial activity.

6.2 Blockage Risks

Microchannels are susceptible to scale buildup, oxidation byproducts, and biological growth, which can restrict flow and sharply reduce heat transfer efficiency.

6.3 Leakage Risks

Aging seals, tubing degradation, and connector fatigue increase the risk of coolant leakage. Since water is conductive, leaks may cause short circuits and catastrophic equipment damage.

7. KINGKA’s Role in Data Center Thermal Management

7.1 One-Stop Thermal Solution Provider

With 15 years of experience, KINGKA is a trusted manufacturer specializing in high-performance heat sinks, custom liquid cooling plates, and precision machined components for data centers, electronics, and renewable energy applications.

Our capabilities span the full product lifecycle—from thermal design and CFD simulation to precision manufacturing, testing, packaging, and global delivery.

7.2 Advanced Manufacturing Capabilities

High-precision CNC Machining with tolerances up to ±0.01 mm

5-axis machining for complex cold plate geometries

Skiving, extrusion, and friction stir welding (FSW) for high-performance thermal structures

Leak-proof Liquid Cold Plate fabrication and integrated assembly

7.3 Rigorous Quality Assurance

ISO 9001:2015 and IATF 16949 certified processes

100% dimensional inspection and CMM measurement (accuracy to 1.5 μm)

Gas/Liquid Leakage Test and Pressure Holding Test

7.4 Engineering-Driven Customization

KINGKA works closely with customers to optimize designs based on real-world operating conditions, balancing performance, reliability, manufacturability, and cost.

8. Enabling the Next Generation of AI Data Centers

As AI computing power accelerates, thermal management has become a strategic infrastructure challenge rather than a secondary engineering consideration. Efficient, reliable, and scalable cooling solutions are essential to unlocking the full potential of high-performance AI chips and data center architectures.

By combining advanced thermal engineering, precision manufacturing, and end-to-end customization, KINGKA is committed to supporting global customers in building high-efficiency, future-ready data center thermal management solutions.