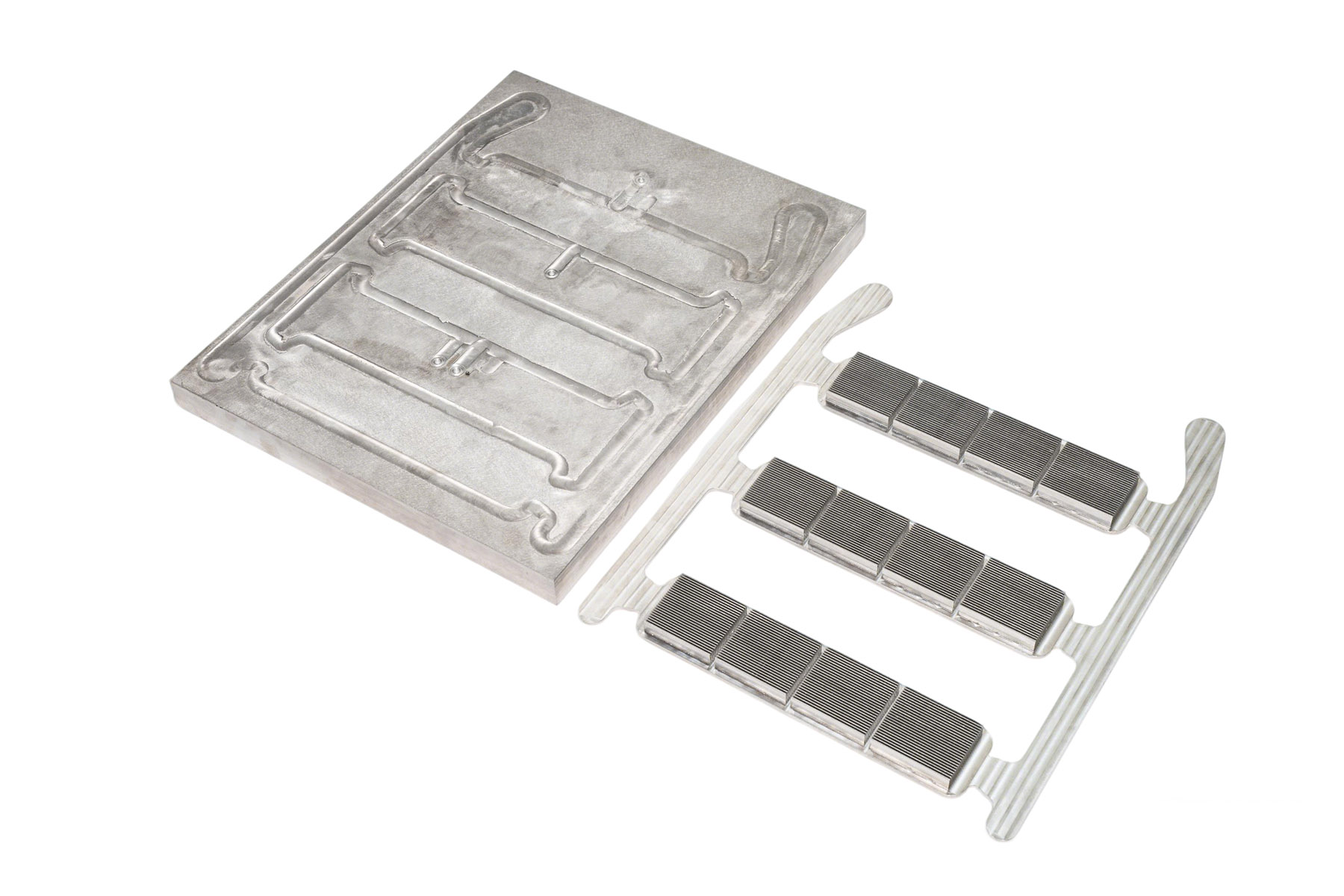

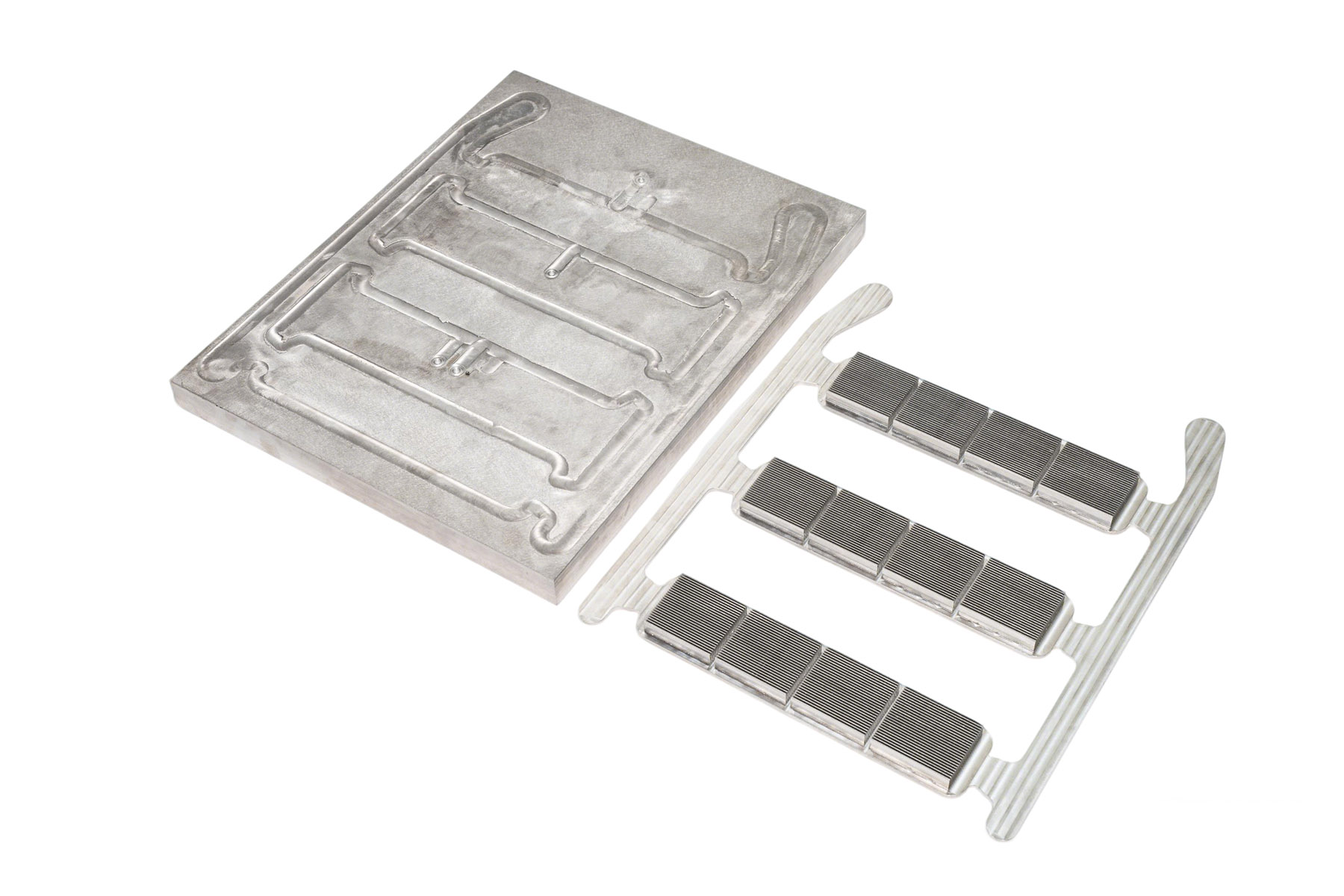

Vacuum-brazed aluminum cold plates are widely used in battery thermal management, power electronics cooling, new-energy vehicles, and high-density servers. As a professional Vacuum Brazing Liquid Cold Plate manufacturer and Vacuum Brazing liquid cold plate supplier, we provide an in-depth overview of how material selection and brazing process control determine the quality and performance of liquid cold plates.

1. Why Vacuum Brazing Is Critical for Liquid Cold Plates

Vacuum brazing is performed under a high vacuum environment (≤10⁻³ Pa), without using flux. This prevents oxidation and ensures a clean, high-strength, leak-free internal channel—critical for any liquid cooling plate or Brazed Liquid Cold Plate. The process offers several advantages:

Production of extremely clean joints

Excellent capillary flow of filler metal

High reliability for complex internal channels

Suitable for thin-walled and multi-layer structures

Ideal for thermal management cold plate applications requiring long-term stability

Compared with mechanical joining or TIG welding, vacuum brazing is currently the most reliable technology for manufacturing liquid cooled cold plates used in EV battery packs, telecom modules, and industrial inverters.

2. Characteristics of 3003 Aluminum Alloy in Vacuum Brazing

Material Overview

3003 is an Al-Mn alloy with:

Vacuum Brazing Behavior of 3003

3003 performs excellently in Vacuum brazing cold plate manufacturing due to its stable structure and lack of volatile elements.

Key characteristics:

Mn refines grains and improves brazing stability

Fewer defects and less erosion when temperature is controlled at 580–590°C

Suitable for thin-walled designs such as honeycomb cores and high-flow cooling channels

This makes 3003 ideal for brazed cold plate designs that prioritize manufacturability and corrosion resistance.

3. Characteristics of 6061 Aluminum Alloy in Vacuum Brazing

Material Overview

6061 is an Al-Mg-Si alloy that:

Vacuum Brazing Behavior of 6061

The main challenge is Mg volatilization at brazing temperature (≈588°C).

Mg evaporation can:

Contaminate the vacuum chamber

Influence filler metal wetting behavior

Narrow the allowable temperature window

Therefore, when designing custom liquid cold plate or high-load high-performance cold plate using 6061, strict control of the following is essential:

Although the process is more demanding, 6061 offers superior mechanical strength—ideal for liquid cold plates used in aerospace, EV battery structural cooling panels, and high-power semiconductor modules.

4. Key Vacuum Brazing Process Parameters for Liquid Cooling Plates

(1) Filler Metal Selection

Common filler metal: 4004 (Al–Si–Mg)

For 6061 structures requiring lower temperatures, advanced low-melting Al-Si-Cu-Mg fillers (514–538°C) can effectively reduce overheating and grain growth.

(2) Temperature and Holding Time

Temperature is the most critical parameter:

Too low → Poor melting, weak bonding

Too high → Base metal erosion, honeycomb dissolution, Mg volatilization (6061)

Holding time must complement temperature and filler metal diffusion behavior.

(3) Degree of Vacuum (≤10⁻³ Pa)

High vacuum eliminates oxide film and ensures clean seam formation.

(4) Surface Cleanliness and Fit-Up Gap

(5) Tooling and Fixturing

Good fixture design helps:

These factors are critical because a single tiny leak inside a brazed liquid cold plate can cause catastrophic failure in EV or industrial cooling systems.

5. Common Defects and Solutions in Brazed Cold Plates

1. Excess Filler Flow (Solder Overflow)

Reasons: Excessive temperature, long holding time, small grain size

Solutions:

2. Base Metal Erosion

Reasons: Over-temperature, long soak time, filler melting point too close to base metal

Solutions:

3. Poor Weld Formation / Porosity

Reasons: Insufficient vacuum, contamination, improper clearance

Solutions:

Improve surface cleaning

Optimize vacuum system

Adjust joint design

6. Material Selection Guide for Liquid Cold Plates

When to choose 3003 cold plates

High corrosion resistance required

Complex internal channels

Cost-effective thermal management

EV battery cooling, heat exchangers, telecom modules

When to choose 6061 cold plates

High strength or structural load needed

Aerospace and defense electronics

High-pressure coolant systems

High-power IGBT or inverter modules

3003 provides a wider process window, while 6061 provides higher joint strength—both suitable for brazed liquid cold plate solutions, depending on your application.

7. How Liquid Cold Plates Work (Overview)

A liquid cold plate uses circulating coolant inside precision-engineered internal channels or micro-channels to absorb and transfer heat away from electronic components.

Working principle:

Heat enters the cold plate base (usually 3003 or 6061 aluminum).

Coolant flows through internal channels formed by vacuum brazing.

Heat is transferred to the coolant by conduction and convection.

The heated coolant exits and is cooled by a radiator or chiller.

This mechanism provides significantly better heat dissipation than natural convection or heatsinks alone, making cold plate liquid cooling the preferred choice for high-power electronics.

Vacuum brazing is essential for manufacturing high-performance cold plates with reliable, leak-free channels.

With optimized filler metals, strict temperature control, and precision fixtures, both materials can deliver excellent results in brazed cold plates, liquid cooling plates, and custom liquid cold plates.

As an experienced Vacuum Brazing Liquid Cold Plate manufacturer and supplier, we offer comprehensive design, machining, and brazing solutions tailored for EV, telecom, aerospace, industrial automation, and high-power electronics cooling.