As artificial intelligence, big data, and high-performance computing (HPC) accelerate, modern data centers face unprecedented thermal challenges. Imagine a building filled with thousands of super-powered computers, performing complex calculations from AI model training to real-time data rendering. Each second generates immense heat. Traditional air conditioning, which has long supported IT infrastructure, is reaching its limits. The "thermal wall" problem threatens to slow innovation—but Direct Liquid Cooling (DLC) technology is changing the game.

What Is Direct Liquid Cooling?

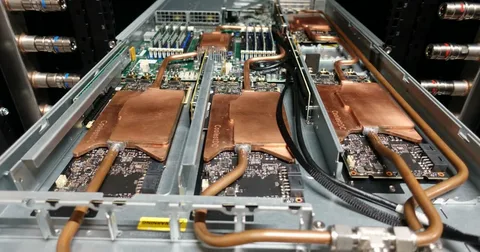

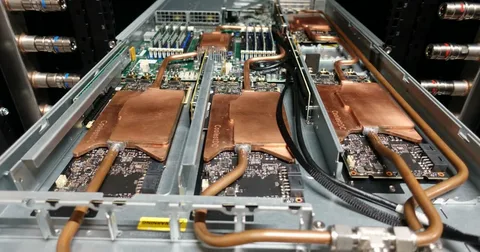

Direct Liquid Cooling (DLC) uses liquid coolant to remove heat from electronic components through direct contact. The core components are liquid cold plates, mounted directly on high-heat processors like CPUs and GPUs. Coolant flows through precision-engineered channels in the cold plates, carrying heat away to a remote heat exchanger for cooling.

Compared to air cooling, DLC offers a more efficient thermal path, enabling higher server density, lower energy consumption, and reliable performance under demanding workloads. Simply put, air cooling is like standing in front of a fan on a hot day, while DLC is like jumping into a cool swimming pool—the difference is dramatic.

Core Principles of DLC

DLC leverages two fundamental heat transfer principles: conduction and convection.

The Thermal Interface Material (TIM) ensures efficient heat conduction by filling microscopic gaps between the chip and cold plate.

Why DLC for High-Performance Data Centers?

Modern AI processors are powerful and generate massive heat. A high-end GPU can have a Thermal Design Power (TDP) exceeding 700W, while a standard CPU might only be 65–120W. Air cooling cannot remove such concentrated heat efficiently, risking throttling or hardware failure. DLC provides precise cooling exactly where it’s needed, supporting full utilization of high-TDP processors.

How DLC Works

A DLC system operates like a car’s water-cooling system:

Coolant Circulation: Pumps drive coolant through a closed loop.

Distribution: The coolant passes through a manifold, splitting into tubes leading to each server or component.

Heat Absorption: Coolant flows through Liquid Cold Plates mounted on CPUs and GPUs, absorbing heat via conduction.

Heat Transport: Warmed coolant returns to a collection manifold.

Heat Rejection: The coolant passes through a heat exchanger, transferring heat to facility water or air, then recirculates.

A Coolant Distribution Unit (CDU) manages the loop, controlling pumps, flow, and temperature.

Single-Phase vs. Two-Phase DLC

Single-Phase: Coolant remains liquid, absorbing heat and circulating to the heat exchanger.

Two-Phase: Special dielectric fluids boil at the hot cold plate, absorbing significantly more heat during phase change. The vapor condenses back to liquid in a condenser, providing extreme cooling efficiency.

DLC System Architecture

DLC can be implemented at different scales:

In-Rack: CDU integrates with a single rack, ideal for high-density upgrades.

In-Row: CDU serves an entire row of racks, balancing efficiency and scalability.

Facility-Level: Connects to the building’s main water system for massive AI/HPC clusters.

Most setups use two separate loops: a primary loop cools servers, while a secondary loop exchanges heat with facility water, preventing direct contact with sensitive IT equipment.

DLC relies on high-precision hardware and advanced coolant design. Key products include:

Liquid Cold Plate / FSW Liquid Cold Plate / Tube Liquid Cold Plate / Brazed Liquid Cold Plate: CNC-machined or precision-welded cold plates designed for maximum thermal performance.

CPU Water Block: Directly replaces traditional heat sinks for processors.

Epoxy Resin Filling Liquid Cold Plate: Enhances structural durability and thermal conductivity.

FSW / Tube Liquid Cold Plate Parts: Precision components ensure safe, efficient coolant flow.

High Efficiency Liquid Cold Plate / Custom FSW Liquid Cold Plate / CNC Machined Liquid Cold Plate: Tailored designs meet unique heat loads, channel geometries, and form factor requirements.

Coolants include water-based mixtures (with glycol for corrosion prevention) or engineered dielectric fluids for leak-proof safety, essential in high-density or critical workloads.

Benefits of Direct Liquid Cooling

Adopting DLC provides numerous advantages:

Energy Efficiency & Sustainability: PUE can drop to 1.1, significantly reducing electricity usage and carbon footprint.

Performance Enhancement: Supports higher server density, quieter operation, and extended hardware lifespan.

Cost Savings: Despite higher initial CAPEX, lower operational energy costs deliver rapid ROI.

Maintenance & Safety: DLC systems are cleaner and easier to service compared to full immersion cooling.

DLC vs. Other Cooling Methods

Air Cooling: Simple but limited in high-power, high-density scenarios.

Immersion Cooling: Powerful but messy, expensive, and less flexible for retrofits. DLC offers precise, targeted cooling and easier integration into standard server racks.

Indirect / Hybrid Systems: Moderate improvements, still rely on air for final cooling, creating bottlenecks. DLC is the optimal choice for AI/HPC workloads and high-density racks.

Future Trends

DLC is evolving rapidly:

Advanced Coolants: Biodegradable, high-performance fluids.

AI-Optimized Systems: Real-time thermal management and predictive cooling.

Edge Computing Integration: Compact DLC solutions for remote or rugged locations.

As computing demands continue to grow, DLC is poised to become the default cooling method for high-density, high-performance infrastructures.

Direct Liquid Cooling is not merely a thermal solution—it is a cornerstone of modern high-performance computing innovation. By leveraging Liquid Cold Plates, FSW Liquid Cold Plates, Tube Liquid Cold Plates, Brazed Liquid Cold Plates, CPU Water Blocks, Epoxy Resin Filling Liquid Cold Plates, and CNC Machined Liquid Cold Plates, DLC enables data centers to operate more efficiently, sustainably, and reliably. For organizations pursuing peak performance, energy savings, and scalable infrastructure, DLC is the future of high-density computing.