Imagine a world where your laptop, smartphone, or data center stays cool without noisy fans. That’s the magic of fanless cooling technology. It’s a quiet, efficient way to manage heat in electronics, transforming how devices work. In this article, we’ll explore what fanless cooling is, why it’s awesome, and how Kingkatech leads the way with over 10 years of expertise.

Key Takeaway Table: Fanless Cooling at a Glance

| Aspect | Details |

|---|

| What is it? | A method to cool devices without fans, using heat sinks or liquid cold plates. |

| Why is it great? | Silent operation, durability, energy savings, and longer device life. |

| Who uses it? | Industries like new energy, data servers, and solar power systems. |

| Kingkatech’s role | Experts in custom cooling solutions for over a decade. |

1. Introduction: What is Fanless Cooling Technology?

Fanless cooling technology keeps electronics cool without the hum of a fan. It uses smart designs like heat sinks and liquid cold plates to pull heat away from devices. Fans can be loud, break easily, and consume a lot of power—fanless cooling avoids all that. It’s a silent, reliable choice appearing in homes, offices, and factories.

Breaking Down the Basics

Instead of pushing air with blades, fanless systems use materials that absorb and spread heat. A heat sink acts like a sponge, soaking up heat from a chip and letting it dissipate naturally. Liquid cold plates use fluids to carry heat away. These methods keep devices cool quietly, perfect for noise-sensitive environments.

Why is Fanless Cooling Important?

Think about your laptop fan roaring when it’s working hard. Now picture it staying cool without that noise. That’s fanless cooling in action. It’s not just for gadgets—big systems like solar panels, electric vehicles, and factory machinery need it too. Fans struggle in dusty or harsh environments, but Kingkatech’s liquid cold plates and heat sinks excel, built to handle any challenge.

A Growing Trend

More industries are switching to fanless cooling. Why? It saves energy and reduces repair costs. Kingkatech’s solutions, like their Skived Fin Heat Sinks, power everything from solar inverters to cloud servers. It’s a quiet revolution that’s impossible to ignore.

2. Why Fanless Cooling Technology Matters

Fanless cooling isn’t just neat—it’s transforming how we handle heat in technology. Here’s why it’s so important.

Benefits of Fanless Cooling

Silence: No more fan buzz disrupting focus in libraries or offices.

Durability: Fewer moving parts mean fewer breakdowns and longer device life.

Efficiency: Lower energy consumption saves money and reduces environmental impact.

Kingkatech’s thermal designs deliver all these advantages, ensuring devices perform optimally while staying quiet.

Industries That Rely on It

Who uses fanless cooling? Plenty of sectors:

New energy systems: Inverters stay cool for optimal performance.

Data centers: Fanless cooling maintains server stability.

Solar power systems: Inverter heat sinks prevent overheating.

Kingkatech builds solutions for all these applications, keeping devices safe under pressure.

Real-World Impact

Imagine a data center running nonstop. Fans would clog with dust or fail, but a Kingkatech Liquid Cold Plate keeps it humming. Or consider electric vehicles—battery cooling without fans improves range and provides quieter rides. Fanless cooling is critical for today’s innovations.

3. How Fanless Cooling Technology Works

How does fanless cooling achieve its magic? It’s simple yet ingenious, with heat sinks and liquid cold plates as the stars.

Heat Sinks: The Heat Sponges

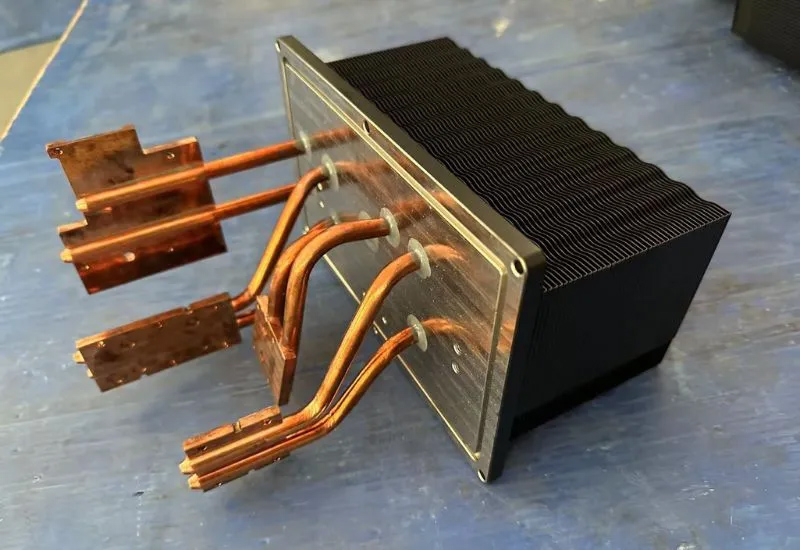

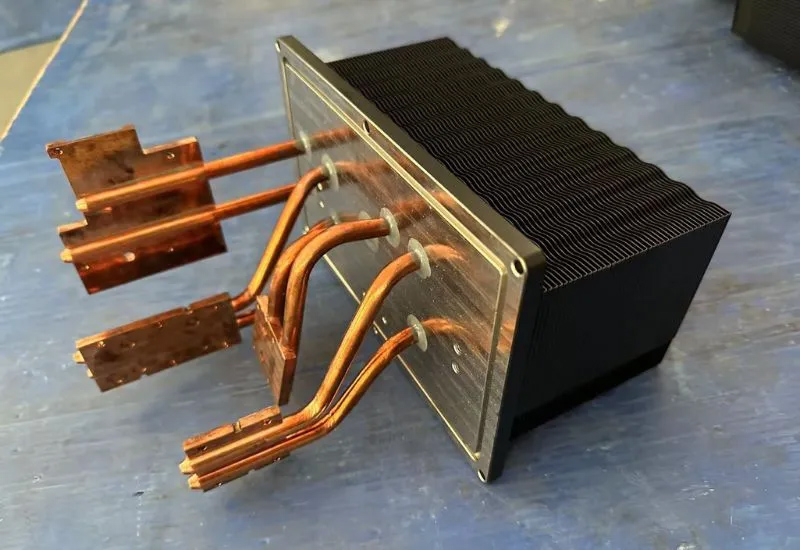

Heat sinks are metallic heroes, often aluminum or copper, that absorb heat from devices and spread it out for natural cooling. Kingkatech produces cold forged, extruded, and skived fin heat sinks, each tailored to specific applications. Adding a heat pipe accelerates heat transfer.

Suggested carousel: Side-by-side images of a skived fin heat sink and a cold forged one.

Captions: “Skived Fin Heat Sink: Precision Cooling” and “Cold forged heat sink: Built Tough.”

Liquid Cold Plates: The Silent Water Coolers

Liquid cold plates take cooling a step further. Fluid flows through channels, carrying heat away efficiently. Kingkatech’s IGBT cold plates handle high-heat devices like 5G telecom systems, providing silent, reliable cooling.

How Heat Moves Away

Heat naturally flows from hot to cold. In fanless cooling, it transfers from the device to a vapor chamber heat sink or liquid cold plate, then disperses into the air or fluid. Kingkatech excels in designs like brazed cold plates, maximizing this natural process.

4. Kingkatech’s Role in Fanless Cooling Technology

Who is Kingkatech?

Kingkatech Industrial Limited, based in China, has over a decade of experience in thermal management. Their team includes engineers from industry leaders like AAVID and Foxconn, delivering expert thermal solutions through custom heat sinks, liquid cold plates, and more.

What Does Kingkatech Offer?

Heat Sinks: 350W heat pipe designs, bonded fin models, and more.

Liquid Cold Plates: High-power FSW plates for demanding applications.

CNC Parts: Precision machined components.

Design Services: End-to-end thermal solutions.

OEM/ODM: Customized to client needs.

Quality You Can Trust

With certifications like ISO9001:2015 and IATF 16949:2016, Kingkatech guarantees top quality and eco-friendly practices. Each product undergoes rigorous testing, with lead times as fast as 3-4 weeks.

5. Real-World Applications of Fanless Cooling Technology

Powering Solar Energy

Solar inverters heat up quickly. Fans often fail in dusty or wet conditions. Kingkatech’s skived fin inverter heat sinks keep them cool and reliable in all environments.

Keeping Data Centers Quiet

Servers generate heat and require constant cooling. Fans consume energy and are noisy. Kingkatech’s liquid cold plates provide quiet, efficient cooling, reducing energy costs by up to 20%.

Electric Vehicles: Silent and Efficient

EV batteries get hot during driving. Fans often don’t fit in tight spaces, so Kingkatech’s battery cooling plates protect batteries and extend their life, offering quieter rides.

A Short Story: The Silent Server Room

A tech company’s server room sounded like a windstorm from fans. After installing Kingkatech’s IGBT cold plates, the noise vanished, servers stayed cool, and maintenance dropped significantly.

6. Why Choose Kingkatech for Fanless Cooling Technology?

Experienced Engineers

The Kingkatech team brings expertise from industry leaders, providing solutions for 5G telecom, medical devices, EVs, and more.

Quick Turnaround and Competitive Prices

Custom heat sinks delivered in 3-4 weeks, at wallet-friendly prices, make Kingkatech stand out.

Certified Quality

ISO9001:2015 and IATF 16949:2016 certifications ensure reliable, eco-conscious products, tested rigorously from CNC components to Peltier modules.

Comparison: Kingkatech vs. Competitors

| Feature | Kingkatech | Generic Competitors |

|---|

| Customization | Fully tailored solutions | Limited options |

| Lead Time | 3-4 weeks | 6-8 weeks |

| Certifications | ISO9001, IATF 16949 | Basic ISO only |

| Industry Focus | New energy, EVs, data centers | General electronics |

The Future of Fanless Cooling Technology

Fanless cooling is here to stay—quiet, energy-efficient, and versatile. Kingkatech leads the industry with over 10 years of experience, delivering smart, affordable cooling solutions.

Looking Ahead

As solar power, EVs, and large-scale data centers expand, fanless cooling adoption grows. Kingkatech continues innovating with TEC cooling and vapor chambers, constantly improving performance.

Final Takeaway

Kingkatech is your partner for silent, reliable tech. Whether it’s solar systems, EVs, or servers, they have the perfect solution. Ditch noisy fans—switch to fanless cooling with Kingkatech today!