The design of liquid cooling plates, commonly used across electronics, data centers, and industrial applications, plays a pivotal role in efficient heat dissipation. However, while focusing on thermal performance, it is crucial to address the potential risk of liquid leakage to ensure the system’s reliability and longevity.

Understanding the Design of Liquid Cooling Plates

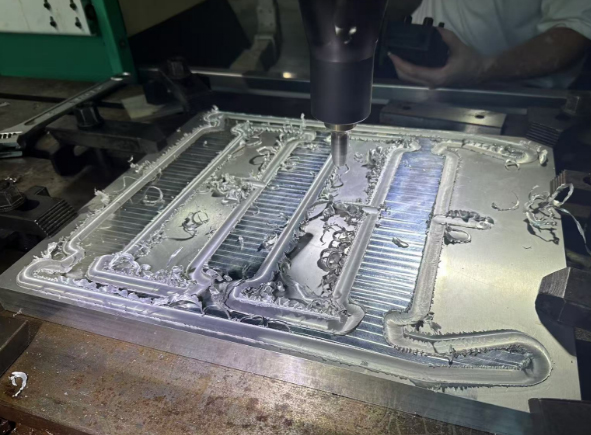

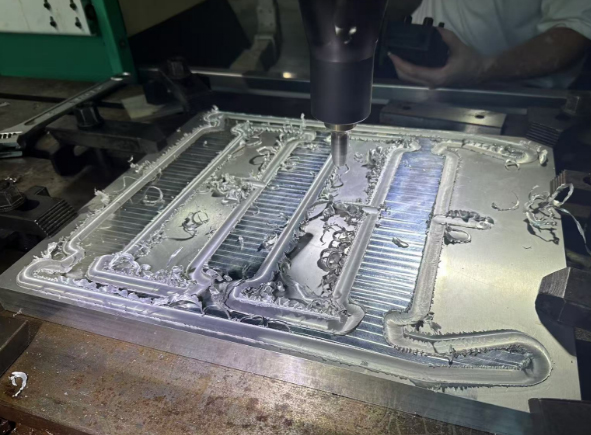

A typical Liquid Cold Plate consists of an aluminum substrate embedded with copper tubes. The manufacturing process often begins with CNC Milling, where grooves are precisely cut into the aluminum base. Pre-bent copper tubes are then pressed onto the aluminum using a punching machine, and any gaps are filled with epoxy resin to minimize thermal resistance. This combination leverages aluminum’s lightweight nature and copper’s high thermal conductivity for optimal cooling efficiency.

Alternatively, engineers may employ Friction Stir Welding (FSW) or Vacuum Brazing to join materials, ensuring stronger bonds and reducing potential leakage points. Once assembled, inlets and outlets are installed to allow circulation of the liquid refrigerant—typically water or a water-alcohol mixture. Water is an ideal cooling medium due to its high thermal conductivity and specific heat capacity, while the alcohol mix prevents freezing in low-temperature environments.

Why Liquid Leakage is a Concern

Liquid leakage in a cooling plate can compromise the system in several ways:

Reduced Cooling Efficiency: Leakage lowers heat dissipation performance.

Component Damage: Liquid infiltration can damage sensitive electronics.

Corrosion and Safety Risks: Leakage can corrode circuits, potentially causing system failures or fire hazards.

Therefore, preventing leakage is essential for both performance and safety.

Common Causes of Liquid Leakage

Several factors can contribute to leakage in cold plates:

Material Stress and Surface Tension:

Welding and joining processes can introduce stress or minor cracks in materials, creating microscopic paths for coolant seepage.

Installation and Process Deficiencies:

Poor assembly, inadequate sealing, or aging silicone rings can compromise the integrity of the liquid cooling plate, especially if the aluminum plate’s flatness is not maintained.

Environmental Factors:

Thermal and cold shocks, as well as pressure fluctuations, may cause seals to fail. Leakage may not appear during initial testing but can manifest under real-world conditions.

Wettability Issues:

Coolants interact differently with surfaces. Rough or defective surfaces increase the risk of leakage by allowing coolant to penetrate microscopic gaps.

Testing for Potential Leakage Risks

Comprehensive testing is critical to ensure leak-proof design. KINGKA, a trusted manufacturer of custom cold plates, uses advanced instruments such as differential pressure and holding pressure testing equipment. Holding pressure tests can last 30 minutes to 2 hours, simulating real-world operating conditions by adjusting liquid temperatures. Additional tests include:

Helium Mass Spectrometry: Detects micro-leaks in liquid cooling plates.

Infrared Thermography: Validates thermal performance.

Material Composition Analysis: Ensures structural integrity of aluminum and copper components.

By integrating these tests into the design and production process, engineers can significantly reduce leakage risks, ensuring better efficiency, reliability, and durability of the cooling system.

One-Stop Solutions by KINGKA

KINGKA is a leading provider of liquid cold plates and thermal management solutions with 15 years of experience. Our capabilities include:

1. R&D and Design Expertise

Advanced CFD Simulations & 3D Modeling: Optimize thermal structures, reducing thermal resistance by up to 20%.

End-to-End Collaboration: From concept to validation, ensuring seamless system integration.

2. Advanced Manufacturing

Precision CNC Machining: ±0.01 mm tolerance for critical components, high-speed 5-axis machining for complex geometries.

High-Precision Sheet Metal Forming: Flatness tolerance <0.1 mm, ensuring optimal thermal contact.

Complete Thermal Product Manufacturing: Integrated machining and forming for heatsink assemblies and tubed cold plates with leak-proof designs.

3. Rigorous Quality Control

Certified Manufacturing Processes: ISO 9001:2015, IATF 16949 compliance.

Advanced Inspection Technology: 3D optical projection, high-precision CMM, and surface roughness testing.

Comprehensive Testing: Leak testing, thermal performance validation, and material verification.

4. Custom Packaging and Logistics

Precision Component Protection: CNC-milled foam inserts, anti-static packaging, and shock absorption.

Sustainable Solutions: Recyclable, biodegradable, and reusable packaging options.

Optimized Logistics: Barcode/RFID tracking, MIL-STD-883 drop tests, and assembly-ready kitting.

Core Products and Services

KINGKA offers a wide range of Custom Cold Plates and related thermal management solutions:

Custom Heat Sinks: Aluminum, copper, and other materials, fully customizable.

Custom Water Cooling Solutions: Heat sinks, water blocks, pumps, reservoirs, and tubing.

Precision CNC Parts: Milling, turning, drilling, and tapping with ±0.01 mm tolerance.

Liquid Cold Plate Parts: FSW and epoxy resin-filled options, leak-proof design.

Our production process involves cross-cutting, stamping, CNC machining, skiving, polishing, sandblasting, tapping, drilling, grinding, sealing tests, silkscreening, and assembly, all meticulously controlled for precision and reliability.

Effective liquid cooling plate design is a delicate balance of thermal efficiency, material selection, precise manufacturing, and rigorous testing. By addressing common causes of leakage and leveraging advanced production technologies, engineers can create robust, leak-free cooling solutions. KINGKA’s one-stop customization services, combined with decades of expertise, ensure that clients receive high-performance liquid cold plates, cool plates, and complete thermal management solutions tailored to their specific needs.