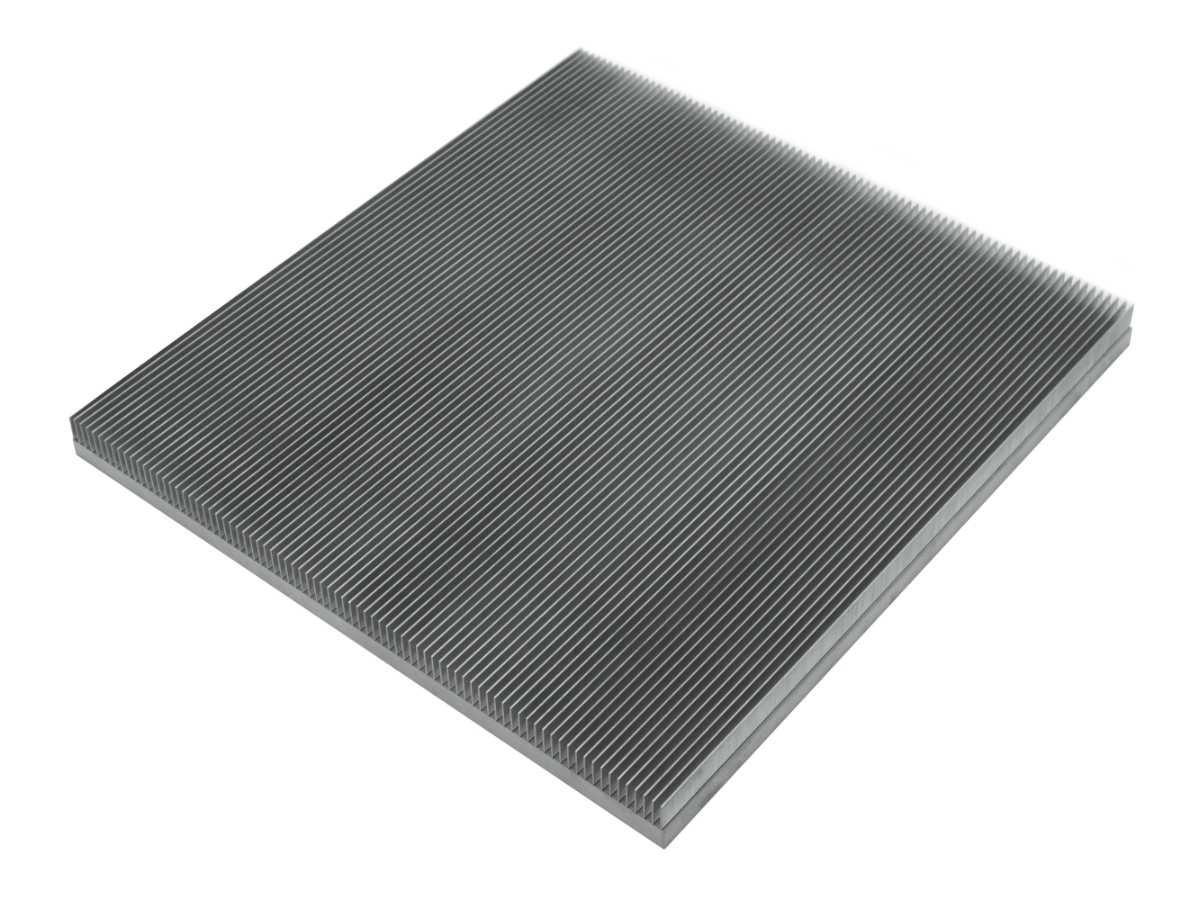

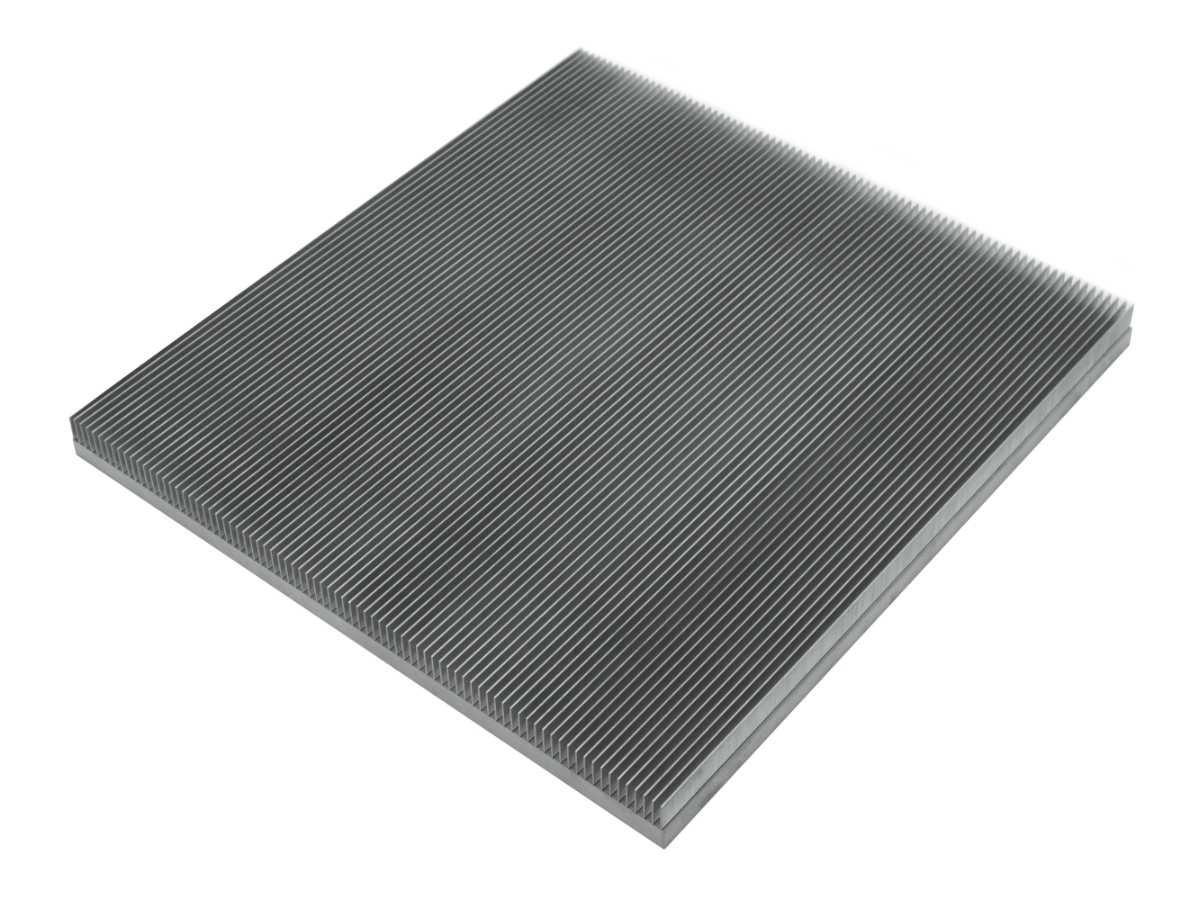

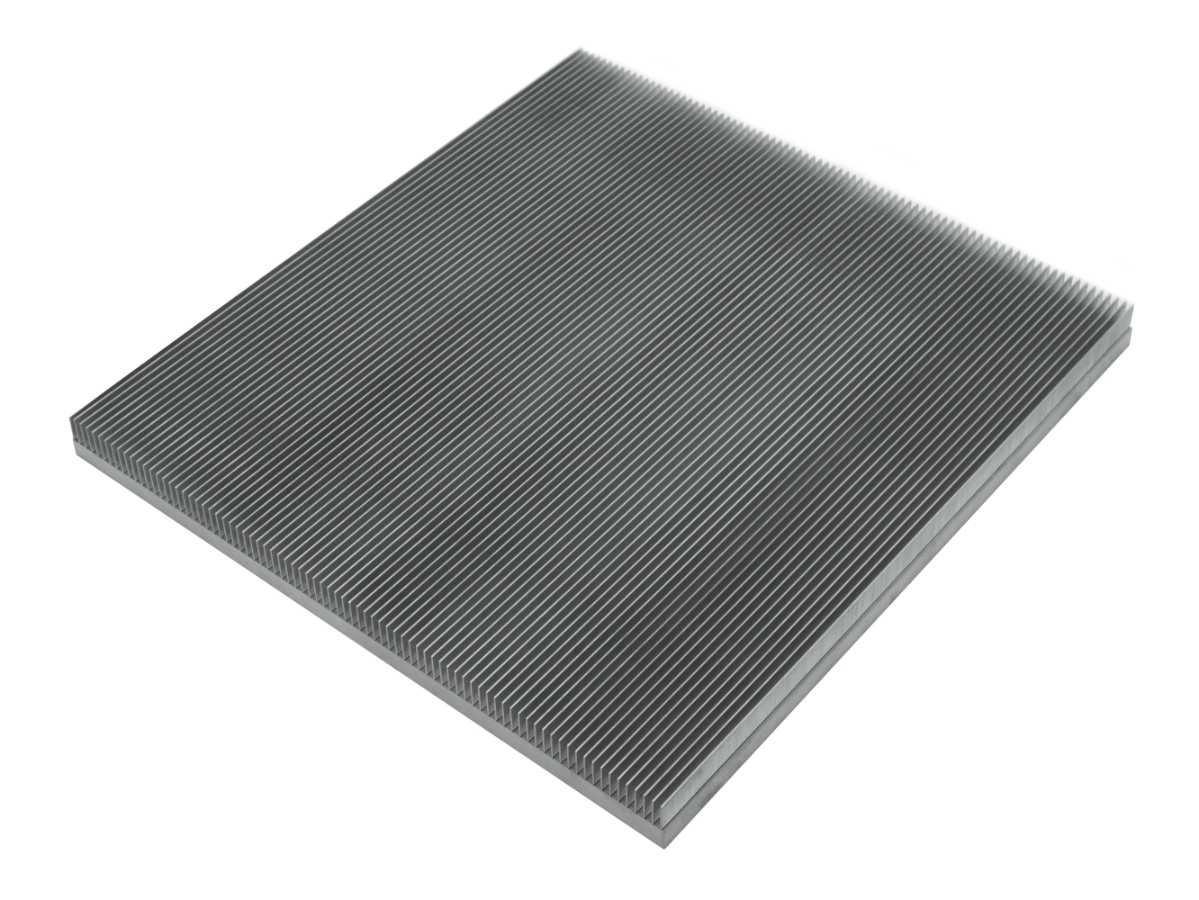

The Skived Fin Heat Sink is a highly efficient heat dissipation component designed to manage thermal energy in high-power electronic devices, automotive systems, aerospace equipment, and communication systems. Manufactured through Precision Skived heat sink Manufacturing techniques, it transforms metal plates into finely cut, high-density fins, dramatically increasing the heat dissipation area and improving thermal performance.

Available in both aluminum and copper, these components are offered as Aluminum skived fin Heat Sink or Copper Skived Fin Heat Sink, providing lightweight, corrosion-resistant, and high-conductivity solutions for demanding applications.

For specialized requirements, we also offer Custom Skived Fin Heat Sink solutions, tailored to meet specific dimensions, thermal loads, and design constraints.

The High-Performance Skived Heat Sink utilizes wire-cutting technology to produce finely skived fins, maximizing surface area and accelerating heat transfer from the heat source to the surrounding air. Compared to traditional heat sinks, Skived Heat Sink designs provide lower thermal resistance, ensuring stable operation of electronic, automotive, and aerospace equipment.

Aluminum Skived Fin Heat Sink is ideal for applications requiring minimal weight, such as aerospace and electric vehicles.

Copper Skived Fin Heat Sink offers superior thermal conductivity while maintaining structural stability.

High-quality metal materials ensure long-term corrosion resistance, extending the lifespan of the heat sink and reducing maintenance costs.

Through CNC Skived Fins and advanced wire-cutting processes, heat sinks can be precisely manufactured in various shapes and sizes. This flexibility allows for Custom Skived Fin Heat Sink solutions to meet unique application requirements.

Although the precision manufacturing process may have slightly higher initial costs, the exceptional heat dissipation performance and long service life of Skived Fin Heat Sink components make them highly cost-effective over time.

1. Electronic Devices

Widely used in computers, servers, routers, and other high-performance electronics.

Ensures stable operation by effectively dissipating heat generated during continuous operation.

2. Communication Equipment

Ideal for base stations, switches, and transmission devices.

Maintains stable performance even under heavy thermal loads.

3. Automotive Industry

Used in electric vehicle battery packs, motor controllers, and power electronics.

Ensures efficient heat dissipation while contributing to lightweight design.

4. Aerospace

Perfect for satellites, spacecraft, and other weight-sensitive equipment.

Provides reliable heat management while reducing overall weight.

5. Medical Equipment

Applied in CT scanners, MRI machines, and large diagnostic devices.

Maintains optimal operating temperatures for safety and precision.

Precision Skived Heat Sink Manufacturing primarily uses wire cutting, stamping, and extrusion techniques.

Wire-cutting technology produces high-density fins with exceptional dimensional accuracy.

Material selection includes aluminum and copper, chosen for excellent thermal conductivity, corrosion resistance, and lightweight characteristics.

Custom designs are available to meet specific device requirements, including unique fin geometries and thermal performance specifications.

Regular Cleaning – Remove dust and debris to maintain optimal heat dissipation performance.

Avoid Impact – Prevent deformation or damage from dropping, squeezing, or transportation.

Check Connections – Ensure heat sinks are properly installed and connected in multi-unit assemblies.

Our Skived Fin Heat Sink, whether as an Aluminum Skived Fin Heat Sink, Copper Skived Fin Heat Sink, or fully Custom Skived Fin Heat Sink, provides high-efficiency, lightweight, and corrosion-resistant thermal management solutions. Leveraging CNC Skived Fins and Precision Skived Heat Sink Manufacturing, these components are ideal for electronics, automotive, aerospace, communication, and medical applications, delivering reliable performance and extended service life.

Q1: What is a Skived Fin Heat Sink?

A: A Skived Fin Heat Sink is a high-efficiency thermal management component manufactured through Precision Skived Heat Sink Manufacturing. It features finely cut, high-density fins that increase the surface area for heat dissipation, ensuring stable operation of electronic and high-power devices.

Q2: What materials are used for Skived Heat Sinks?

A: Common materials include aluminum and copper. Aluminum is lightweight and corrosion-resistant (Aluminum Skived Fin Heat Sink), while copper provides superior thermal conductivity (Copper Skived Fin Heat Sink).

Q3: What are the main advantages of Skived Fin Heat Sinks?

A: The High-Performance Skived Heat Sink offers:

Efficient heat dissipation due to high-density fins

Lightweight design suitable for aerospace and automotive applications

Corrosion resistance for harsh environments

Long service life and low maintenance costs

Q4: Can Skived Fin Heat Sinks be customized?

A: Yes. We provide Custom Skived Fin Heat Sink solutions tailored to specific dimensions, thermal loads, and device requirements. Advanced manufacturing processes like CNC Skived Fins allow for precise fin geometries and high thermal efficiency.

Q5: Where are Skived Fin Heat Sinks commonly used?

A: Applications include:

Electronic devices: computers, servers, routers

Communication equipment: base stations, switches, transmitters

Automotive industry: battery packs, motor controllers, EV electronics

Aerospace: satellites, spacecraft

Medical equipment: CT scanners, MRI machines

Q6: How is a Skived Heat Sink maintained?

A: To ensure optimal performance:

Regularly clean to remove dust and debris

Avoid mechanical impact or deformation during handling and transportation

Check multi-unit connections to ensure stability and proper thermal contact

Q7: How does it compare to other heat sinks?

A: Compared to traditional heat sinks, a Skived Fin Heat Sink provides:

Higher thermal conductivity

Increased heat dissipation area

Lightweight and compact design

Longer lifespan, reducing overall maintenance costs

Q8: What manufacturing processes are involved?

A: Precision Skived Heat Sink Manufacturing typically uses wire cutting, stamping, and extrusion. The wire-cutting process creates high-density fins with exceptional accuracy, producing Aluminum Skived Fin Heat Sink or Copper Skived Fin Heat Sink designs suitable for high-performance applications.

Kingka Tech Industrial Limited

We specialize in precision CNC machining and our products are widely used in telecommunication industry, aerospace, automotive, industrial control, power electronics, medical instruments, security electronics, LED lighting and multimedia consumption.

Address:

Da Long New Village, Xie Gang Town, Dongguan City, Guangdong Province, China 523598

Email:

Tel:

+86 137 1244 4018